HYDRAULIC SYSTEM RT770E

2-26

Published 11/26/2014, Control # 447-05

Procedure E - Charge Air Cooler Valve Relief

Pressure

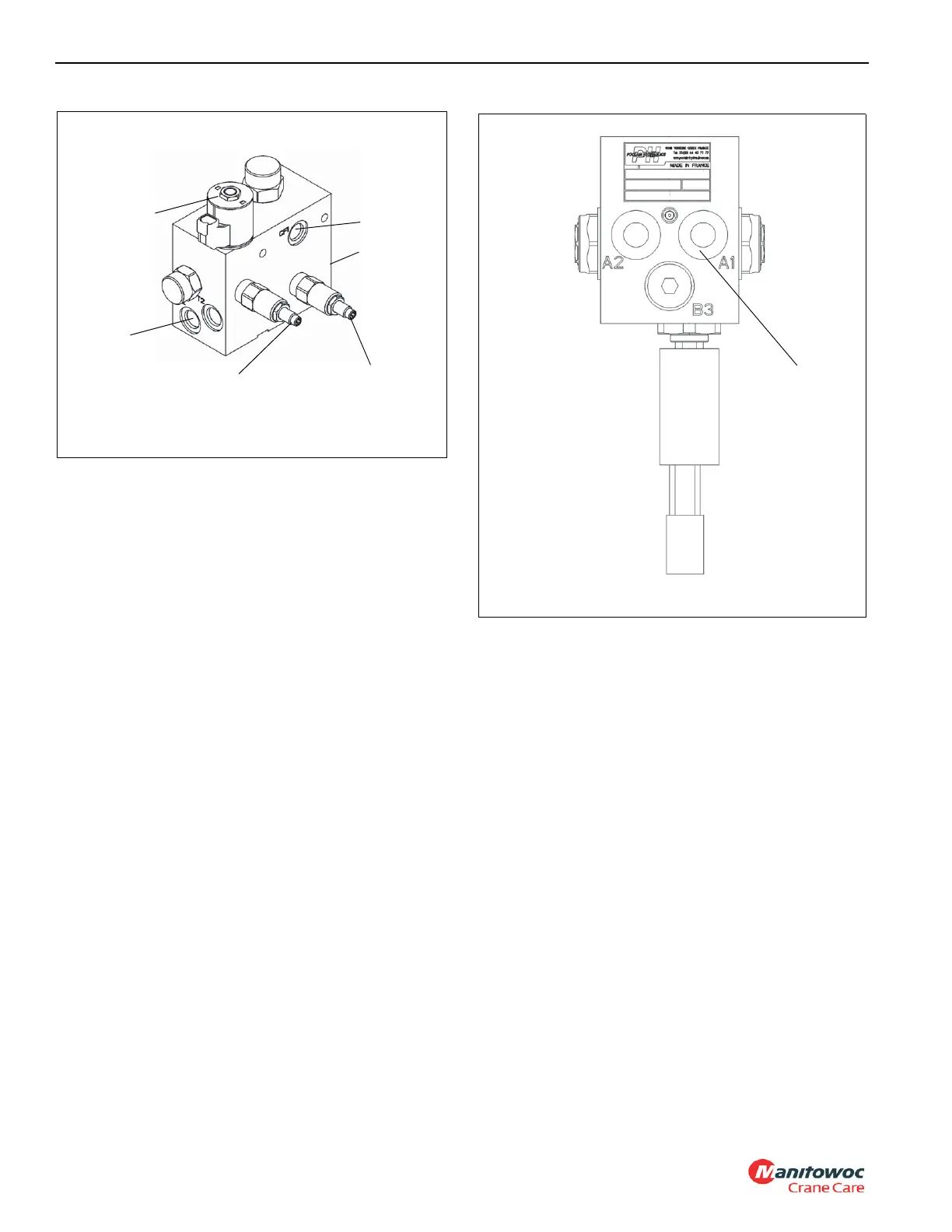

1. Install pressure check diagnostic quick disconnect

(Parker PD240) with gauge onto Test Port, Figure 2-9.

2. Unplug CAC Solenoid.

3. Start engine and operate at Full RPM. Adjust “CAC Fan

Relief Valve” to 69 bar +4/-0 (1000 psi +50/-0)

NOTE: Note: If brake valve begins charging accumulators,

test port pressures above 124.1 bar (1800 psi) may

be observed. Wait until charge is complete and

then adjust CAC Relief to 69 bar +4/-0 (1000 psi

+50/-0).

4. Remove pressure gauge from the Test Port, and

reconnect CAC Solenoid.

Procedure F - Brake Dual Accumulator

Charge Valve Pressure Limits

1. With the engine off, discharge all of the pressurized oil

stored in the accumulators by depressing the service

brake pedal on the cab floor 8-10 times.

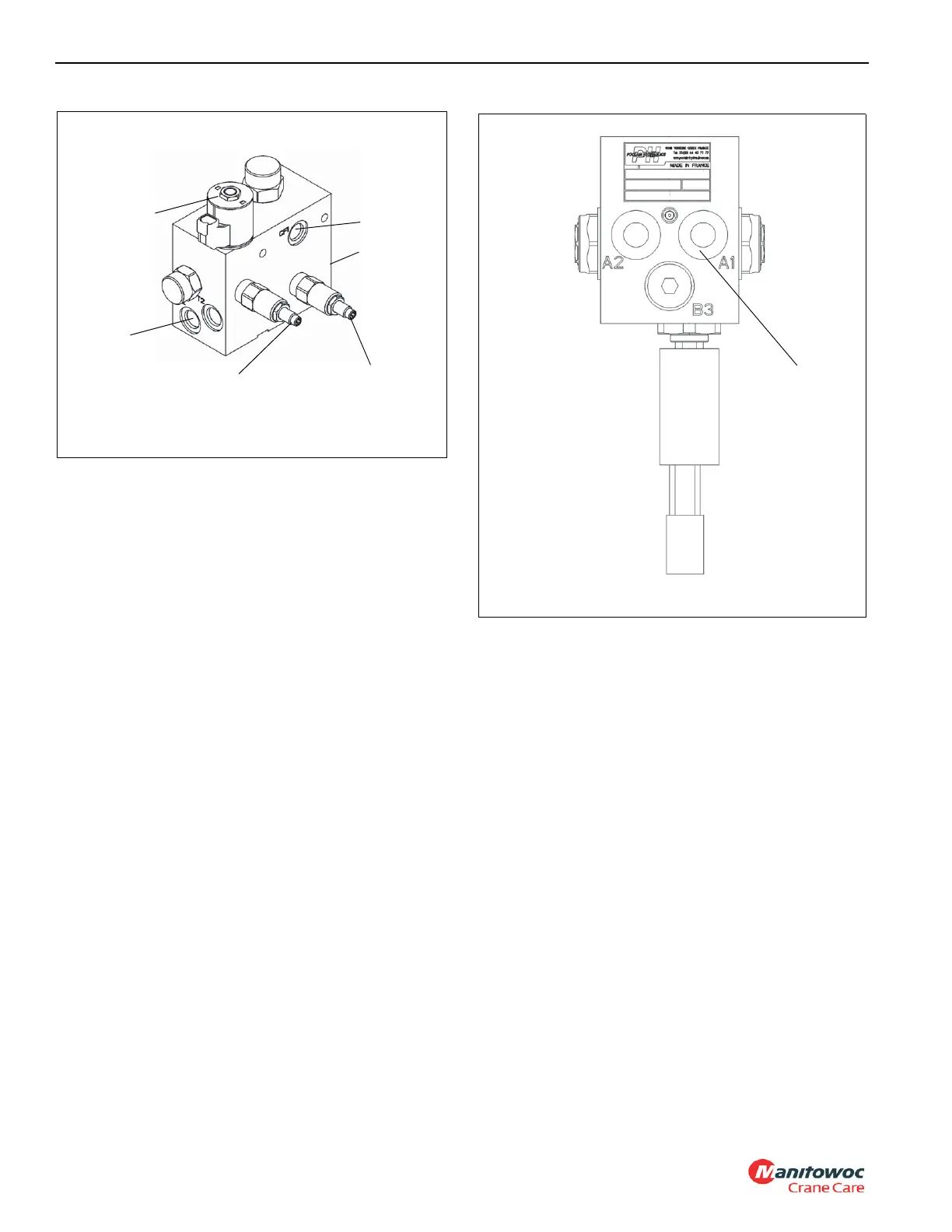

2. Install a pressure gauge at the service brake dual

accumulator charge valve “A1” pressure test port (1,

Figure 2-10).

3. Start and idle the engine. The charging valve will

immediately start to charge the accumulators. Watch the

pressure gauge. The high charge limit pressure should

read 174 bar +5/-10 (2320 psi +72/-145) when the valve

stops charging. The accumulator charge valve is non-

adjustable.

4. With the engine running, bleed off the hydraulic pressure

stored in the accumulators by pushing the service brake

pedal on the cab floor until the gauge reads about

134 bar (1950 psi). Listen to hear when the service

brake dual accumulator charge valve starts to recharge.

Push the service brake pedal once more; the valve

should start to recharge. Watch the pressure gauge. The

low charge limit should be 134 bar ±10 (1950 psi ±145)

when the valve starts to recharge. The accumulator

charge valve is non-adjustable.

5. Turn engine off. Remove the pressure gauge.

Procedure G - Accumulator Pre-Charge

Pressure

1. With the engine off, discharge all of the pressurized oil

stored in the accumulators by depressing the service

brake pedal on the cab floor several times. Remove the

gas valve guard and cap on the accumulator

Figure 2-11.

2. Before attaching the gas charging assembly Figure 2-11

onto the accumulator gas valve, back the gas chuck “T”

handle all the way out (counterclockwise).

3. Close the charging assembly bleed valve. Attach the

swivel nut onto the gas valve and tighten to 1.1 to

1.7 Nm (10 to 15 lb-in).

Tes t P or t

FIGURE 2-9

7798

CF1 Port

Adjustable Inlet

Relief Valve

CF2 Port

Adjustable

CAC Fan

Relief Valve

CAC Solenoid

Loading...

Loading...