Manitowoc Published 12-10-19, Control # 258-05 3-17

MLC90A-1/MLC100-1 OPERATOR MANUAL OPERATING CONTROLS AND PROCEDURES

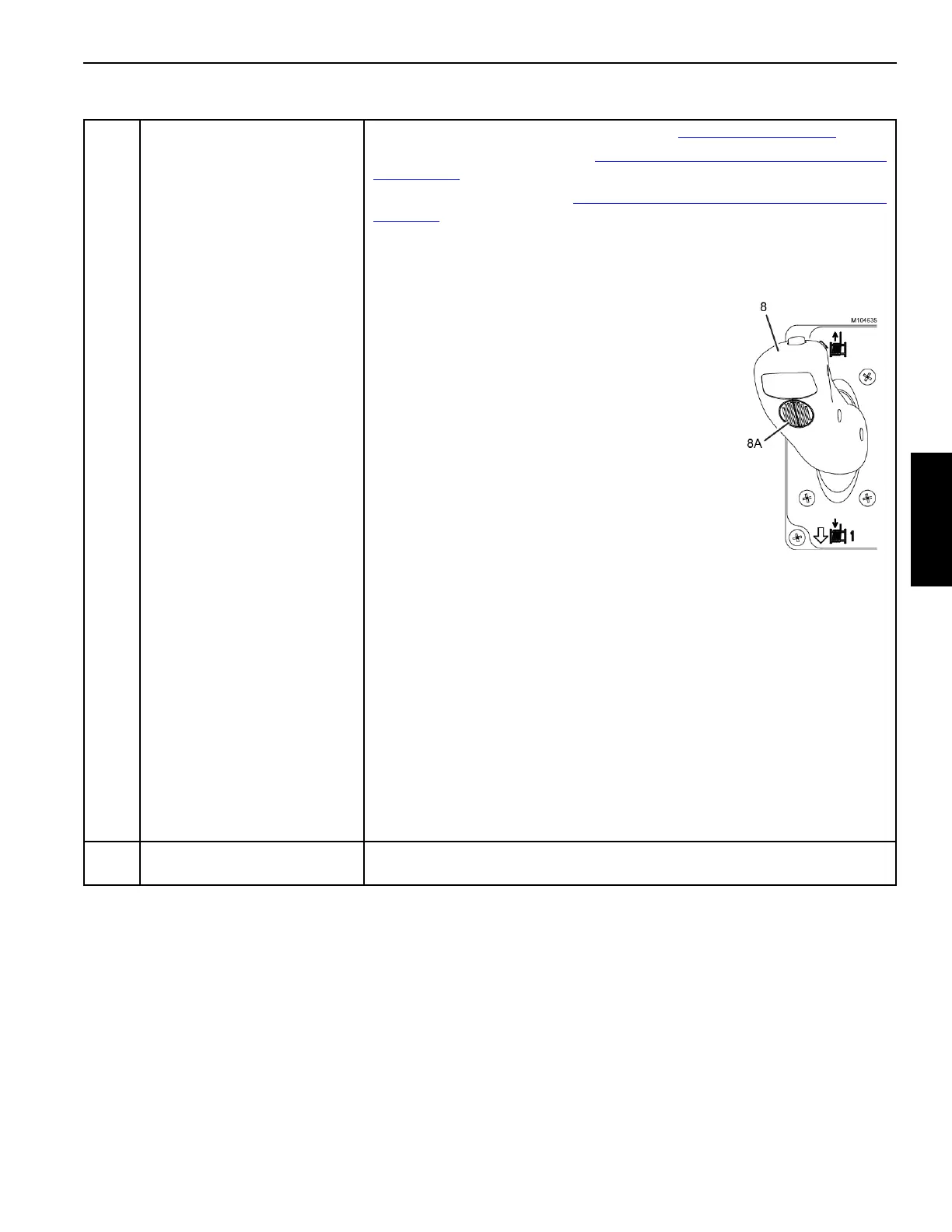

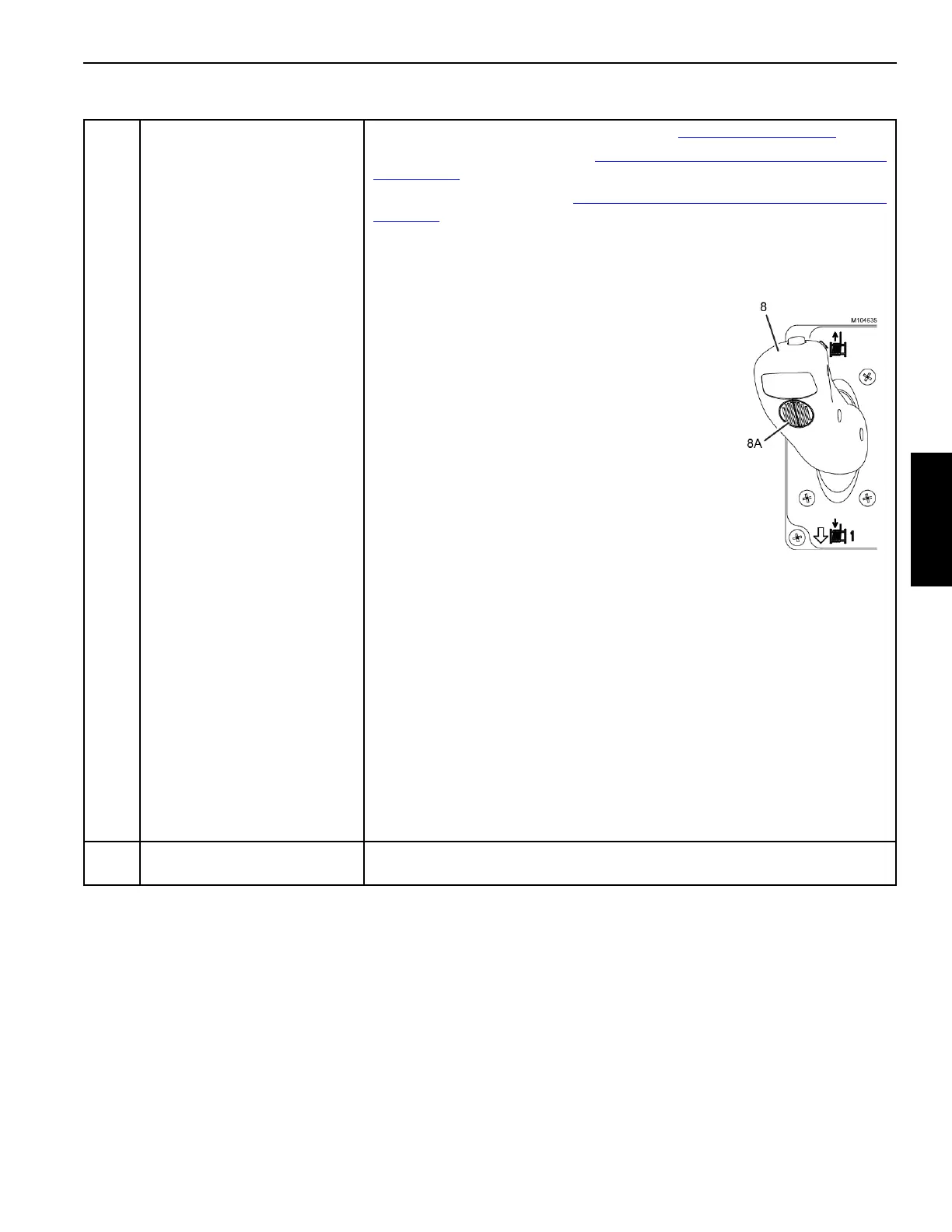

8 Load Drum Control Handles

For drum and control handle identification, see Figure 3-2 on page 3-16

.

For non-free fall load drums, see Load Drum Operation—Liftcrane Full Power

on page 3-40.

For free fall load drums, see Load Drum Operation—Liftcrane Free Fall on

page 3-41.

NOTE The free fall option is available only for Drums 1 and 2.

• Pull the handle BACK to RAISE the load. The

drum brake releases and speed increases in

relation to handle movement.

• Release the handle to OFF (center) to STOP the

load. Speed decreases to off and the drum brake

applies to stop and hold the drum in position. If

equipped with free fall, make sure the brake

pedal is depressed or the load will continue

to lower under its own weight.

• Push the handle FORWARD to LOWER the

load. The drum brake releases and speed

increases in relation to handle movement.

NOTE Drum 1 and 2 High Speed Operation with

CCM software Rev 0.073 and ODM software

Rev 1.010 or prior:

• If EITHER Drum 1 or 2 is un-parked, high

speed operation is enabled for that drum.

• If BOTH drums are un-parked, high

speed operation is disabled for both

drums.

Drum 1 and 2 High Speed Operation with CCM software Rev 0.074 and

ODM software Rev 1.011 or later:

• Drum 1 and 2 High Speed Operation is enabled by adjusting the

programmable speed limiter on the Speed and Torque Settings

Screen over 100% (see F2315 for Speed and torque Settings

Screen operation).

• If both drums are in use, high-speed operation is temporarily

disabled for both.

8A Drum Rotation Indicator

A pin-type actuator in the control handle for each load drum moves up and down

to signal the operator by feel that the drum is turning.

Table 3-5. Right Console

Loading...

Loading...