National Crane Published 03-18-2019 Control # 582-04 2-5

NBT30H-2 OPERATOR MANUAL SAFETY PRECAUTIONS

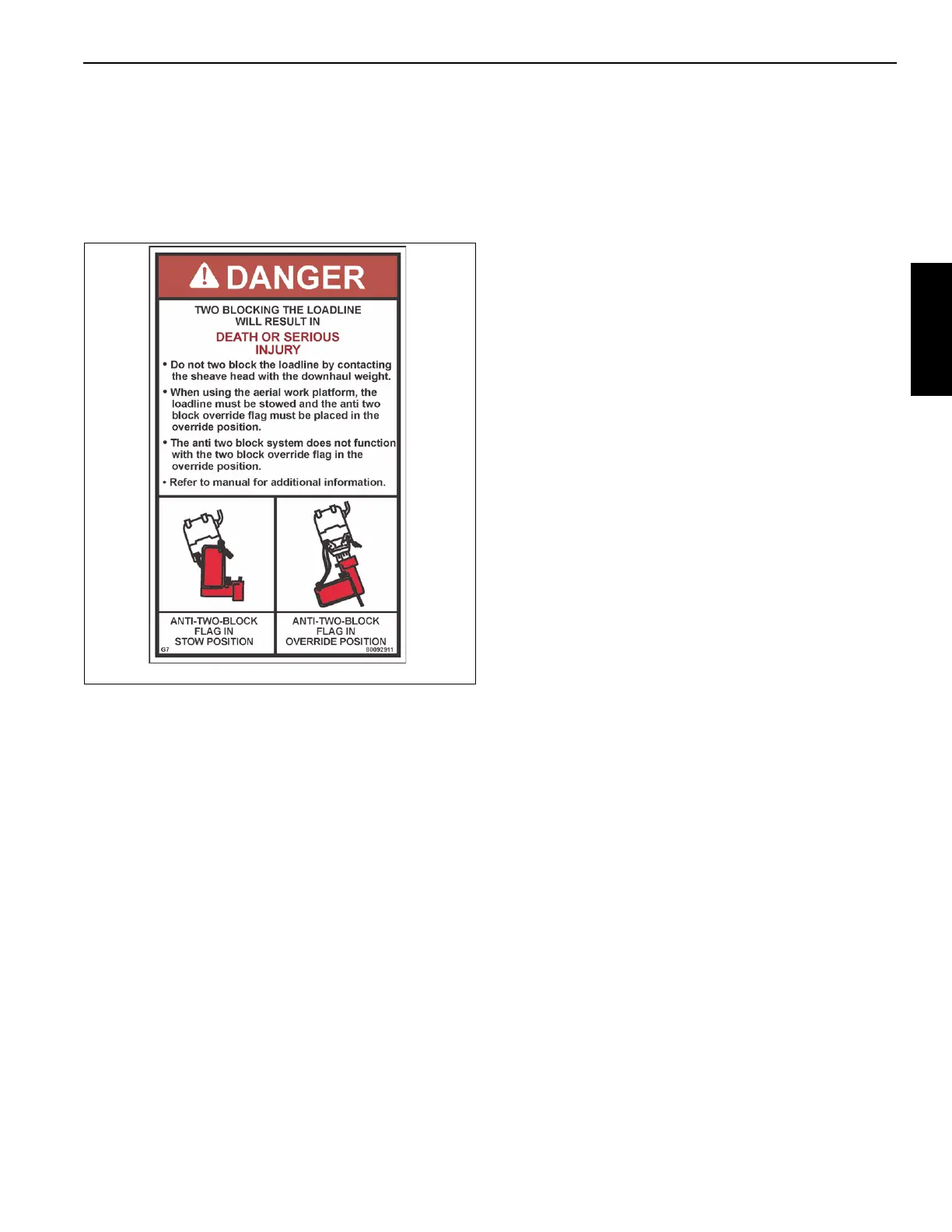

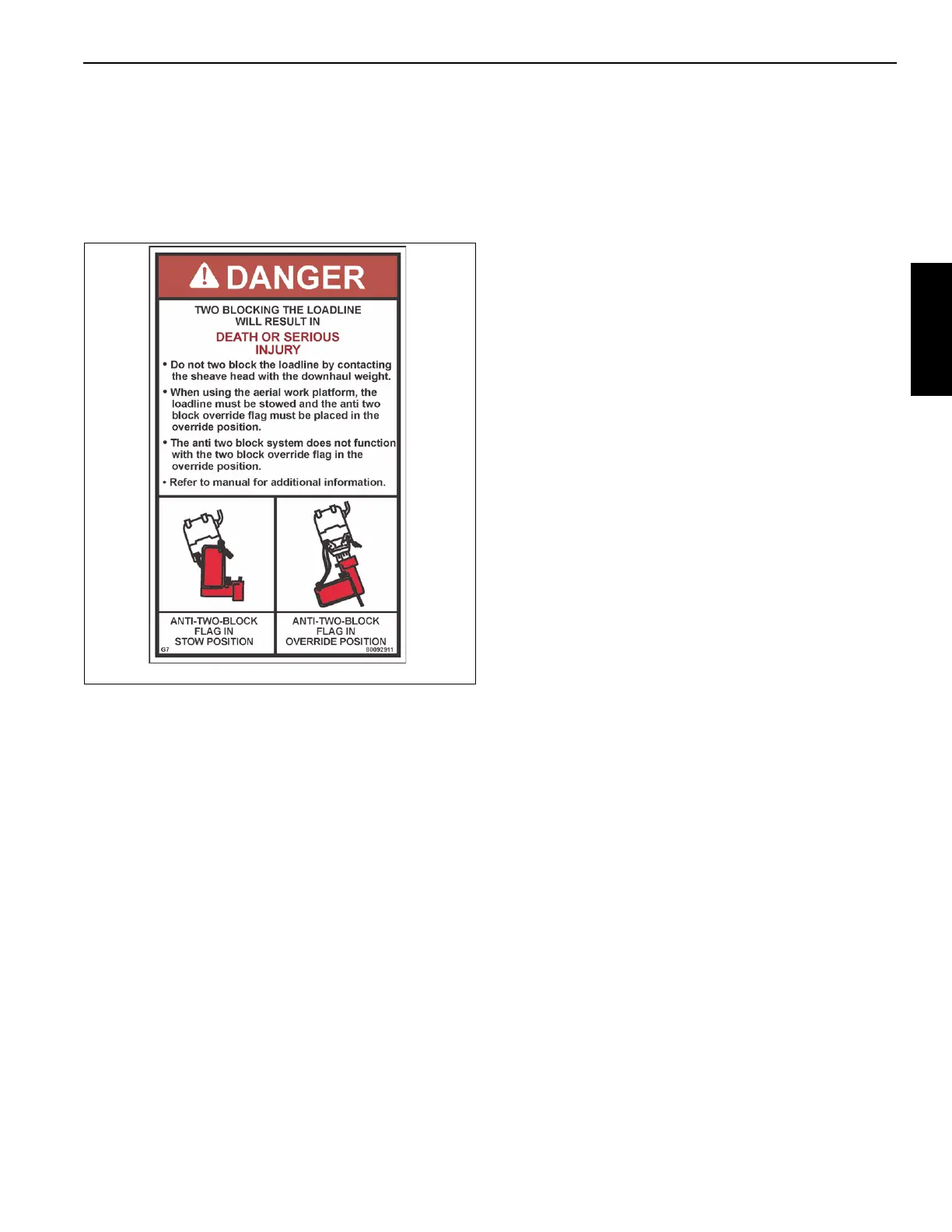

Two-blocking occurs when the load block (hook block,

headache ball, rigging, etc.) comes into physical contact with

the boom (boom nose, sheaves, jib, etc.). Two-blocking can

cause hoist lines (wire rope), rigging, reeving, and other

components to become highly stressed and overloaded in

which case the rope may fail allowing the load, block, etc. to

free fall.

Two-blocking is more likely to occur when both the main and

auxiliary hoist lines are reeved over the main boom nose and

jib nose respectively. An operator, concentrating on the

specific line being used, may telescope or lower the boom

allowing the other hoist line attachment to contact the boom

or jib nose, thus causing damage to the sheaves, or causing

the rope to fail, dropping the lifting device to the ground and

possibly injuring personnel working below.

Caution must be used when lowering the boom, extending

the boom or hoisting up. Let out load line(s) simultaneously

to prevent two-blocking the boom tip(s) and the hook block,

etc. The closer the load is carried to the boom nose the more

important it becomes to simultaneously let out hoist rope as

the boom is lowered. Keep load handling devices a minimum

of 107 cm (42 in) below the boom nose at all times.

Two-blocking can be prevented. Operator awareness of the

hazards of two-blocking is the most important factor in

preventing this condition. An Anti-Two-Block System is

intended to assist the operator in preventing dangerous two-

block conditions. It is not a replacement for operator

awareness and competence.

Never interfere with the proper functioning of operational

aids or warning devices.

Working Area Limiter (If Equipped)

This equipment may be equipped with a working area limiter

as part of the RCL system, designated as either Work Area

Definition System (WADS) or Working Range Limiter (WRL).

You must read and understand the operator manual before

operating the working area limiter system. Become familiar

with all proper operating procedures and with the

identification of symbol usage.

The working area limiter is intended to be used as an aid to

the operator. It is not a substitute for safe equipment

operating practices, experience, and good operator

judgments.

EQUIPMENT STABILITY/STRUCTURAL

STRENGTH

To avoid death or serious injury, ensure that the equipment is

on a firm surface with load and equipment’s configuration

within capacity as shown on the equipment’s Load Chart and

notes.

Ensure all pins and floats are properly installed and outrigger

beams are properly extended before lifting on outriggers. On

models equipped with outriggers that can be pinned at the

mid-extend position (vertical stripe, if applicable), the

outriggers must also be pinned when operating from the mid-

extend position.

Use adequate cribbing under outrigger floats to distribute

weight over a greater area. Check frequently for settling.

Read and follow the following safety decal for equipment

with a single front outrigger.

9250

Example decal. For reference only.

Loading...

Loading...