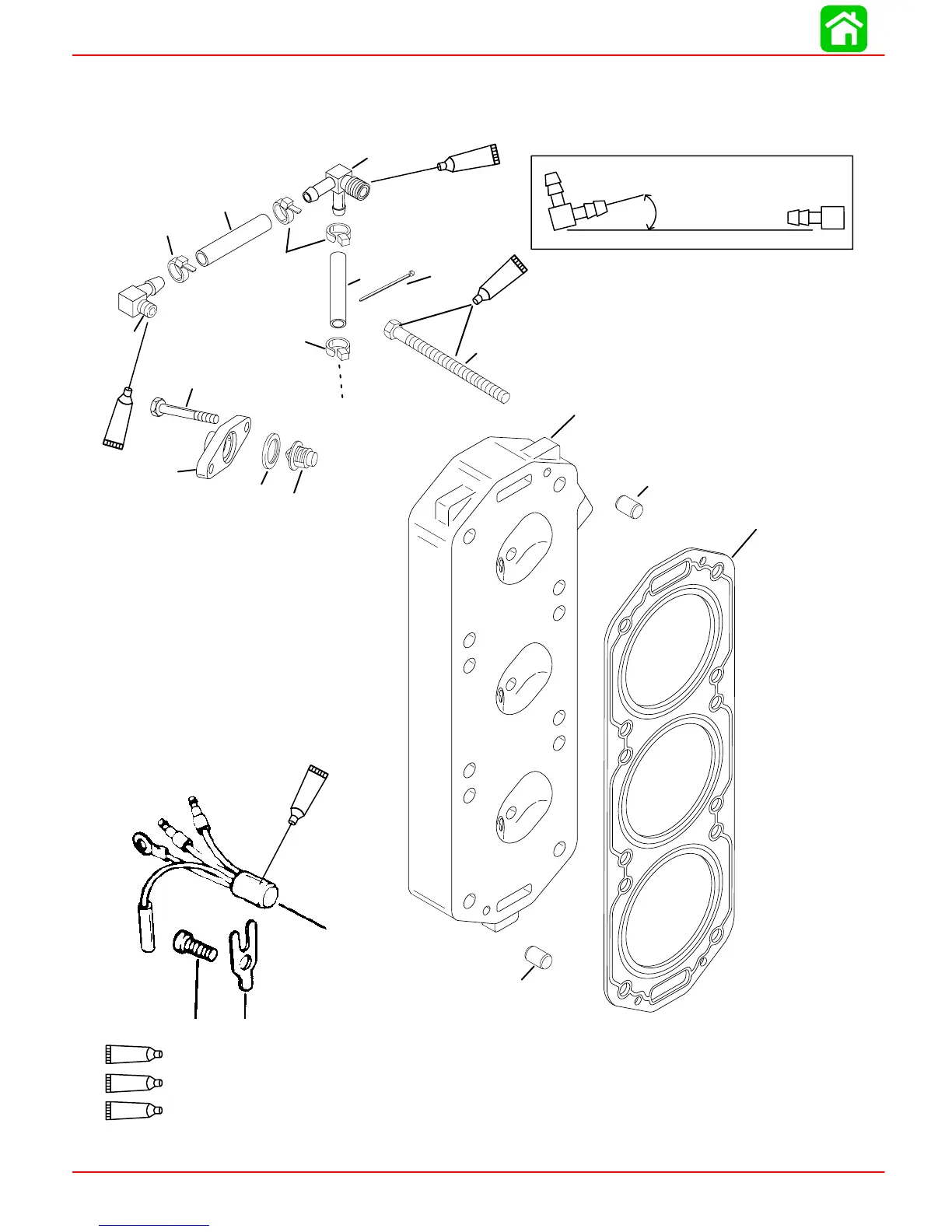

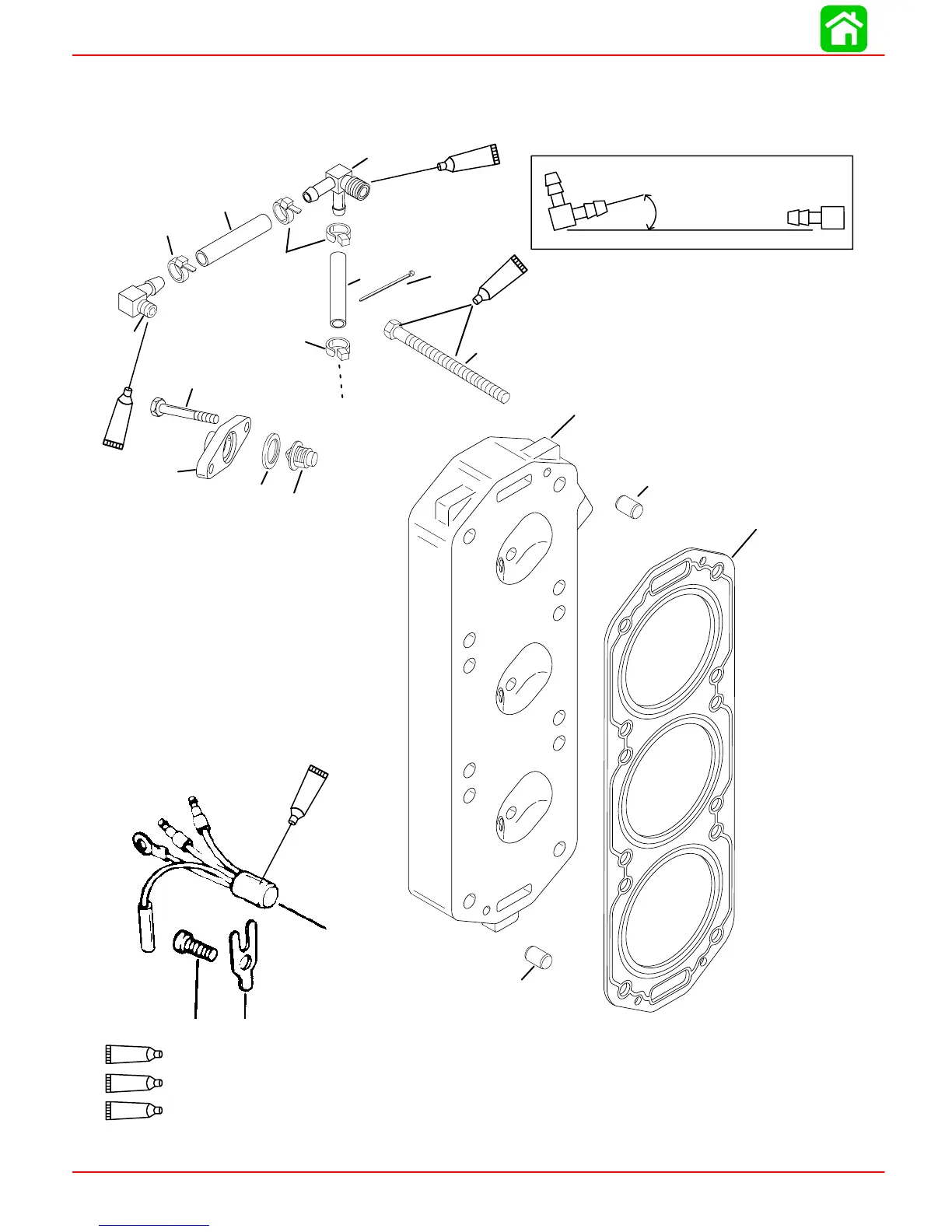

POWERHEAD

Page 4A-8 90-855347R1 JANUARY 1999

Cylinder Head

3

4

5

6

7

8

9

11

10

14

1516

1

2

13

4

12

13

A

13

13

9

9

6

14

15°

Back of Engine

Water Fitting Orientation

Looking Down at Top of Block

Dielectric Grease (92-823506--1)

6

Loctite PST Pipe Sealant (92-809822)

9

14

2 Cycle Outboard Oil (92-13249A24)

A = TO STRAIGHT FITTING ON BACK OF EXHAUST PLATE

Loading...

Loading...