20

3. Lower the back end of the rip fence

onto the guide surfaces of the rear

rail.

4. Push the locking lever down in order

to automatically align and secure the

fence.

USING THE MITRE GAUGE (See Fig.

18)

The mitre gauge provides greater

accuracy in angled cuts. For very close

tolerances, test cuts are recommended.

There are two mitre gauge channels, one on either side of the blade. When

making a 90° crosscut, you can use

either mitre gauge channel. When

making a bevel crosscut (the blade tilted

in relation to the table), the mitre gauge

should be located in the slot on the right

so that the blade is tilted away from the

mitre gauge and away from your hands.

The mitre gauge can be turned 60° to the right or left. Positive stops at 0° and

45° can be located by pushing in the stop pin.

1. Loosen the locking knob

2. With the mitre gauge in the mitre gauge slot, rotate the gauge until the

desired angle is reached on the scale.

3. Retighten the locking knob.

To check the angle indicator:

Loosen the locking knob, place a 90º square against the mitre gauge rod and

the mitre gauge base, and verify that the angle indicator is at 0º. If it is not,

loosen the locking screw under the rod in order to adjust the angle indicator

to 0º, and then retighten the locking screw.

USING THE SLIDING EXTENSION TABLE (See Fig. 19)

Increase the length of the saw table by

using the extension table.

1. Set the rip fence to 12 1/2” (31.8

cm).

2. Push the extension table locking

lever toward the back in order to

unlock the lever.

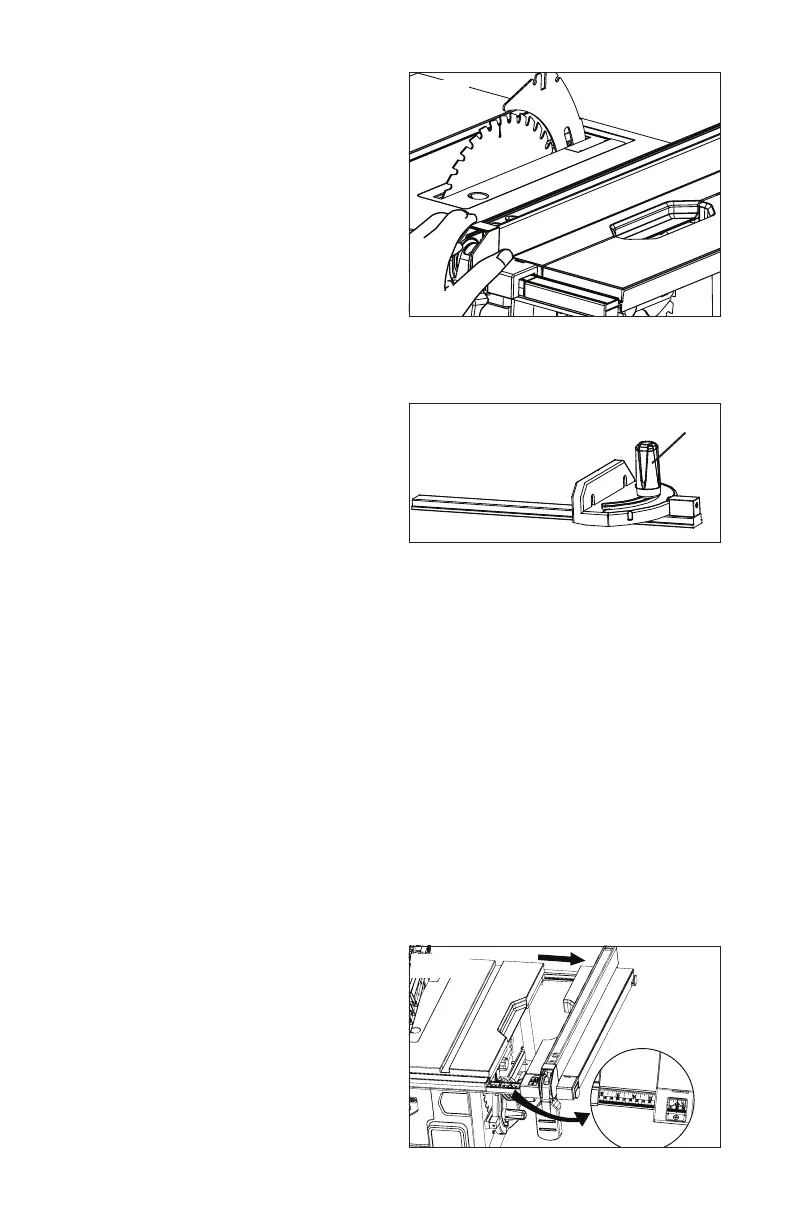

Fig. 17

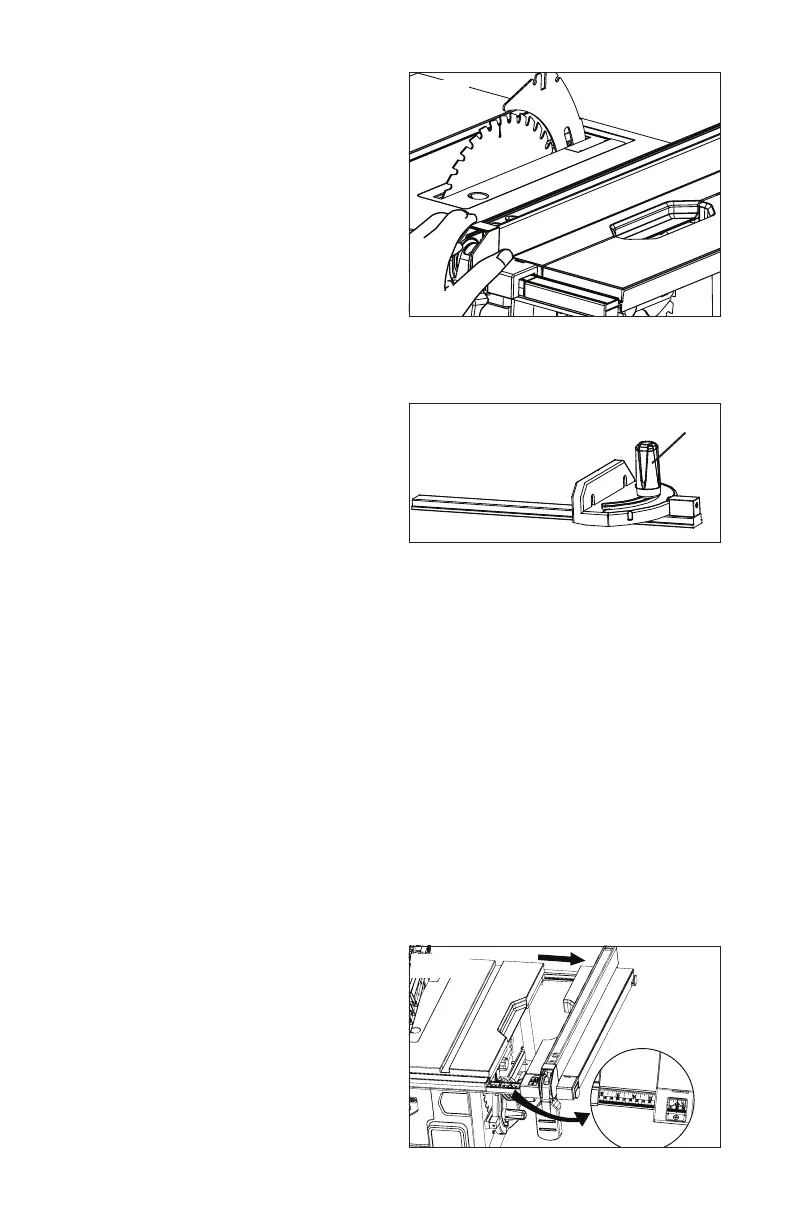

Fig. 19

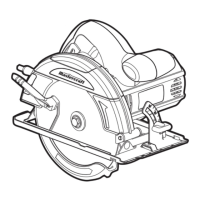

Fig. 18

LOCKING KNOB

EXTENSION

TABLE

Loading...

Loading...