5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

1.5.8 Adjustment of Ignition Time for Fuel Injection

(1)Dismantle the pipe mounted on the injection pump (fuel and lubricating oil).

(2)Loosen the mounting bolts for the injection pump.

(3)Adjust towards the direction far away from engine in the “Advance” case, and adjust

towards the direction near to engine in the “Delay” case, at the same time while ignition time

is being confirmed according to the key points of 1.5.7.

(4)Tighten all the bolts assembled for injection pump, and confirm the ignition time again,

after adjustment is completed.

(5)Assemble the oil drain valve used for the first cylinder, and assemble the respective pipes

at their original separate positions.

1.5.9 Determination of Compression Pressure (Refer to Fig 1-18.)

(1)Detach the heating spark plug and injection pipes totally.

(2)Fit on the pressure gauge in the assembling part for heating spark plug of the first cylinder

(calibrated value as 500N/㎝

2

).

(3)Use fully charged battery to allow the rotation of starting device, and measure the pressure

at this point.

(4)Measure up to the 6

th

cylinder with the same method, and measure for more than two times,

respectively. Then figure out their respective average values, Compression Pressure: 304N/㎝

2

(Limit Value 255N/㎝

2

)

Fig 1-18

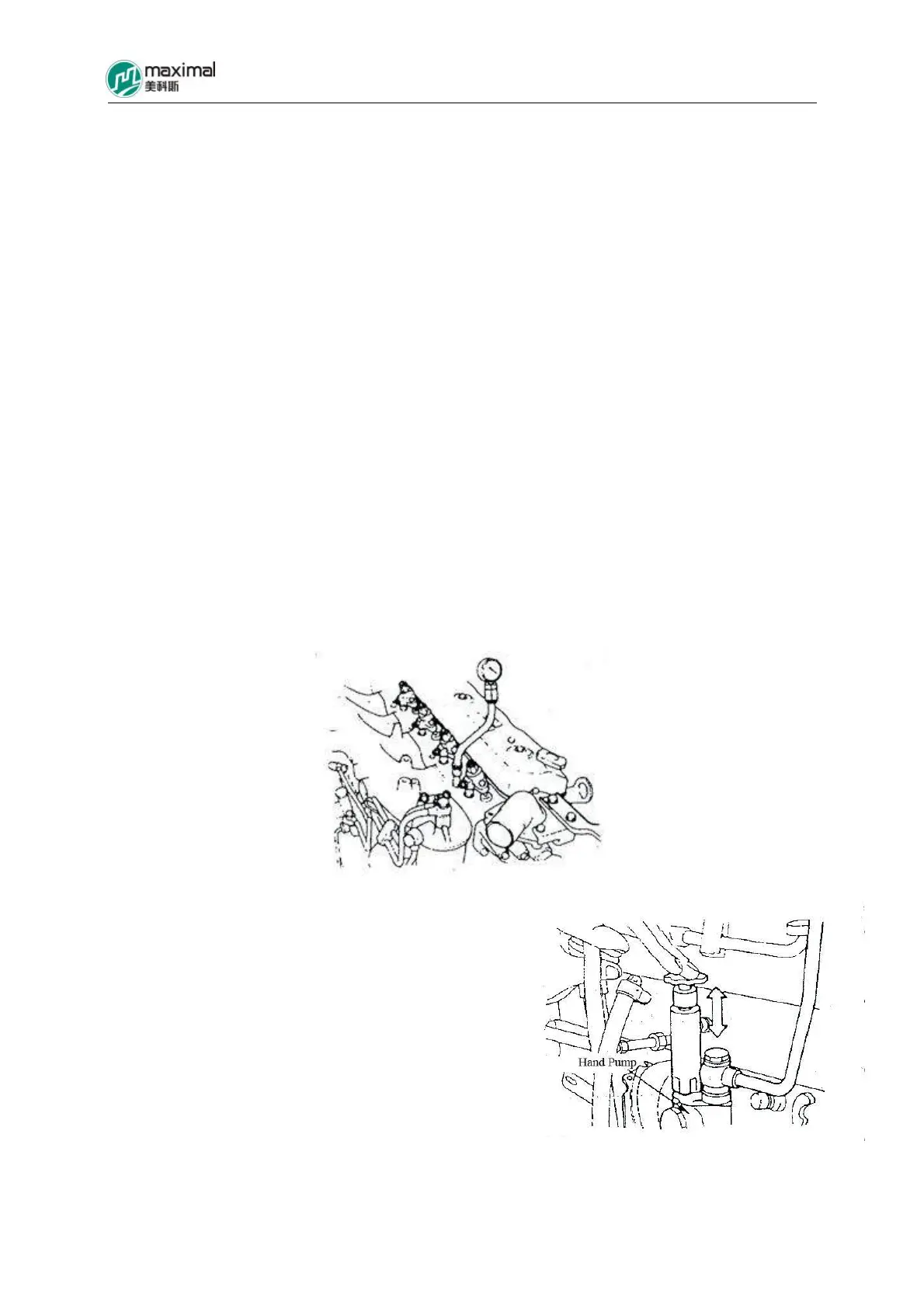

1.5.10 Exhaust of Injection Pump (Refer to Fig

1-19.)

(1)Loosen the exhaust plug for injection pump.

(2)Operate the hand pump slowly, until no air

bubble appears in the place of exhaust plug.

(3)Then tighten the exhaust plug.

Fig 1-19

Loading...

Loading...