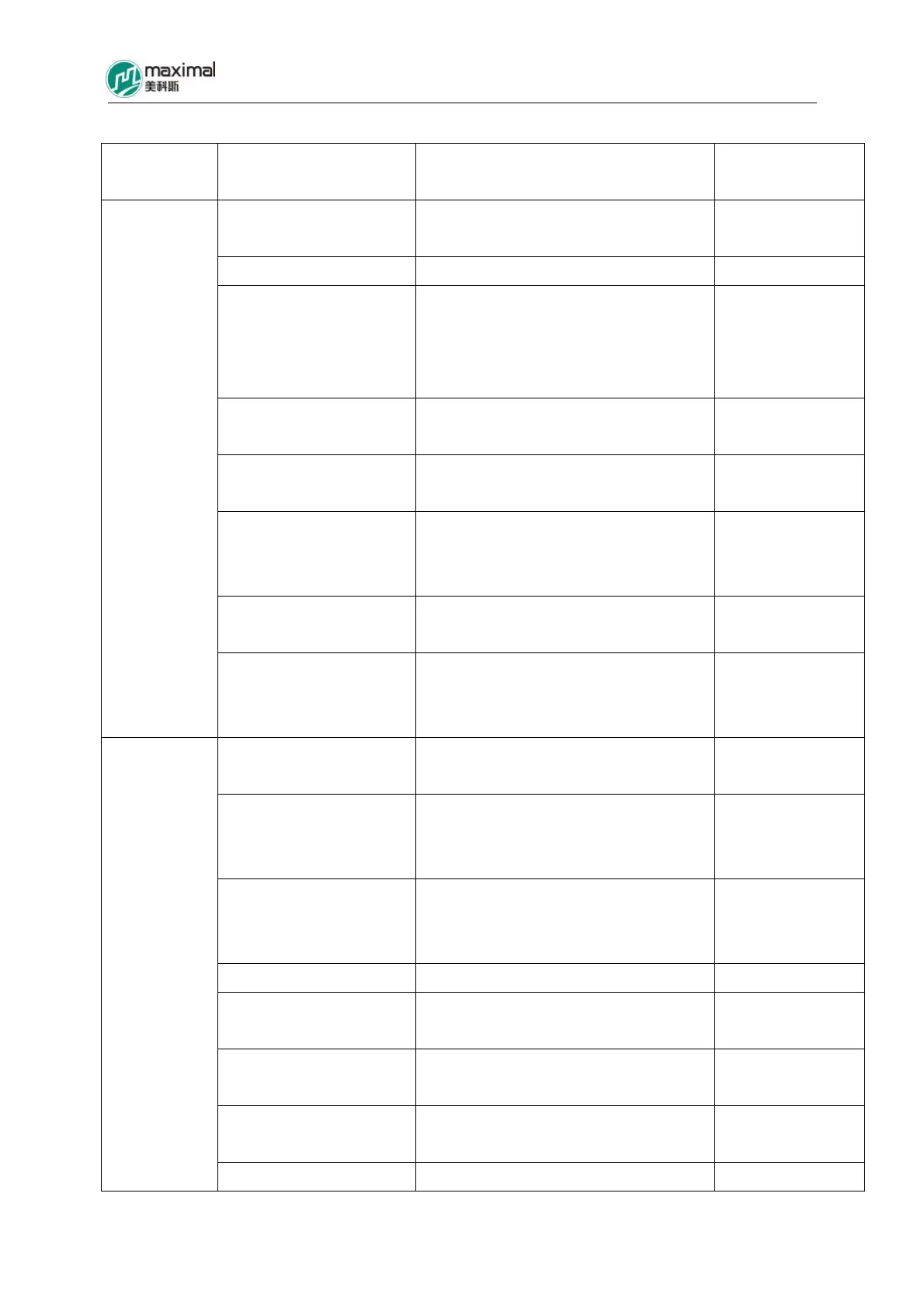

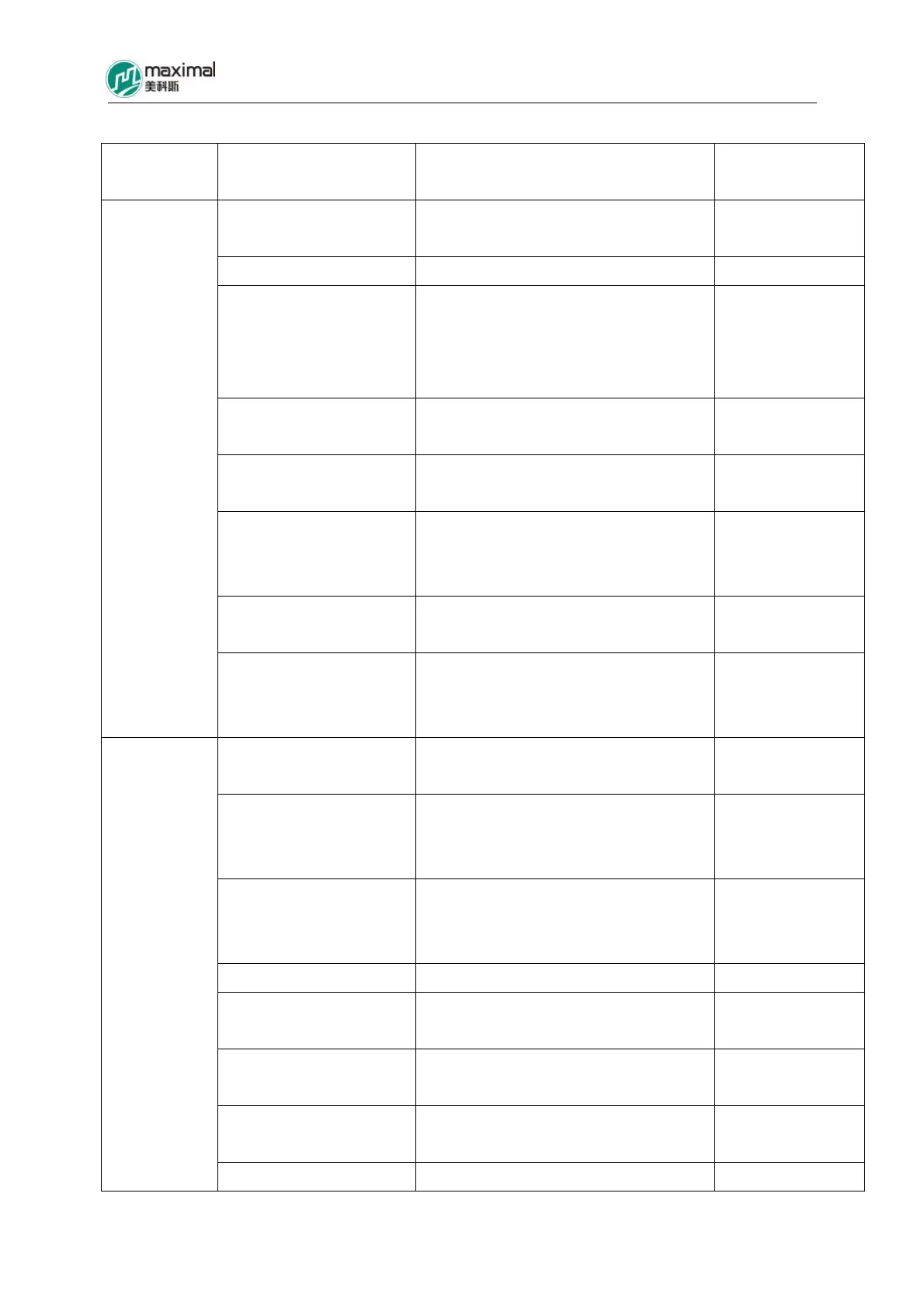

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

Table 3-2 Insufficient Power

Part

Cause for Failure

Generation

Examination Method Removal Method

A. Too Low Oil

Pressure

(1)Oil Level Low Examining oil level Oil to be added

(2)Air Sucked at the Oil

Suction Side

Examining joint and oil pipe Joint to be

re-tightened and

sealing part to be

replaced

(3)Oil Filter Blocked Disassembling and examining To be cleaned or

replaced

(4)Displacement of Oil

Feed Pump Insufficient

Disassembling and examining To be replaced

(5)Main Overflow

Valve Disc Spring

Distorted

Examining spring tension

(6)Seal Ring or O-Ring

Damaged or Worn out

Disassembling and examining To be replaced

Torque

Converter

B. Flywheel Damaged

or Other Parts in

Collision

Extracting a small quantity of oil and

examining whether or not extraneous

substance exists

To be replaced

A. Improper Use of Oil

or Blistering

Examining

(1)Air Sucked at Oil

Suction Side

Examining joint and oil pipe Joint to be

re-tightened or

replaced

(2)Oil Pressure of

Torque Converter too

Low or Blistering

Measuring pressure Pressure to be

adjusted

B. Clutch Skidding

(1)Oil Pressure Low Measuring Pressure Pressure to be

adjusted

(2)Seal Ring Worn out Disassembling, examining, and

measuring

To be replaced

(3)Clutch Piston Ring

Worn out

Disassembling and examining

Transmission

(4)Friction Plate Worn Disassembling and examining start To be replaced

Loading...

Loading...