5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

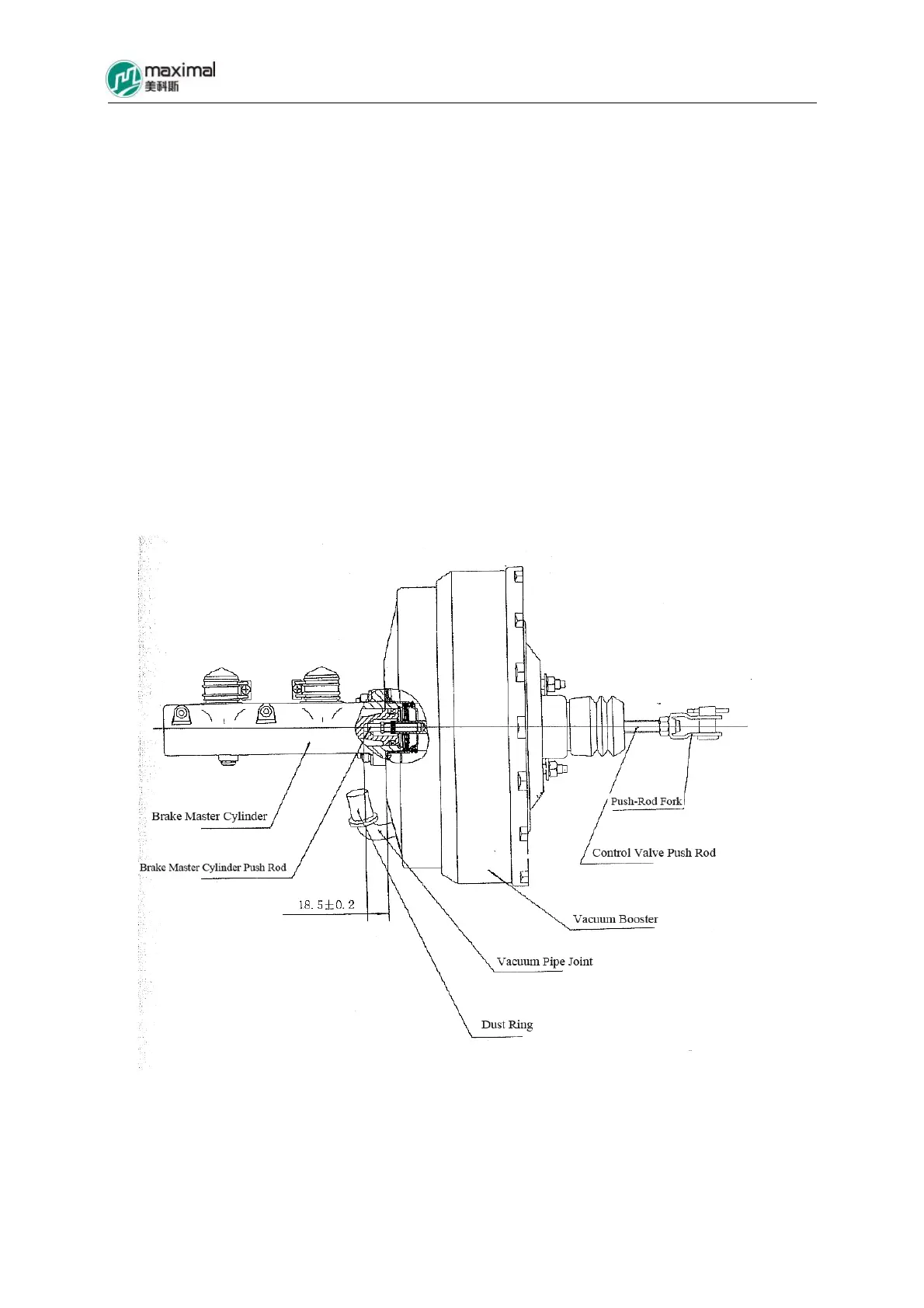

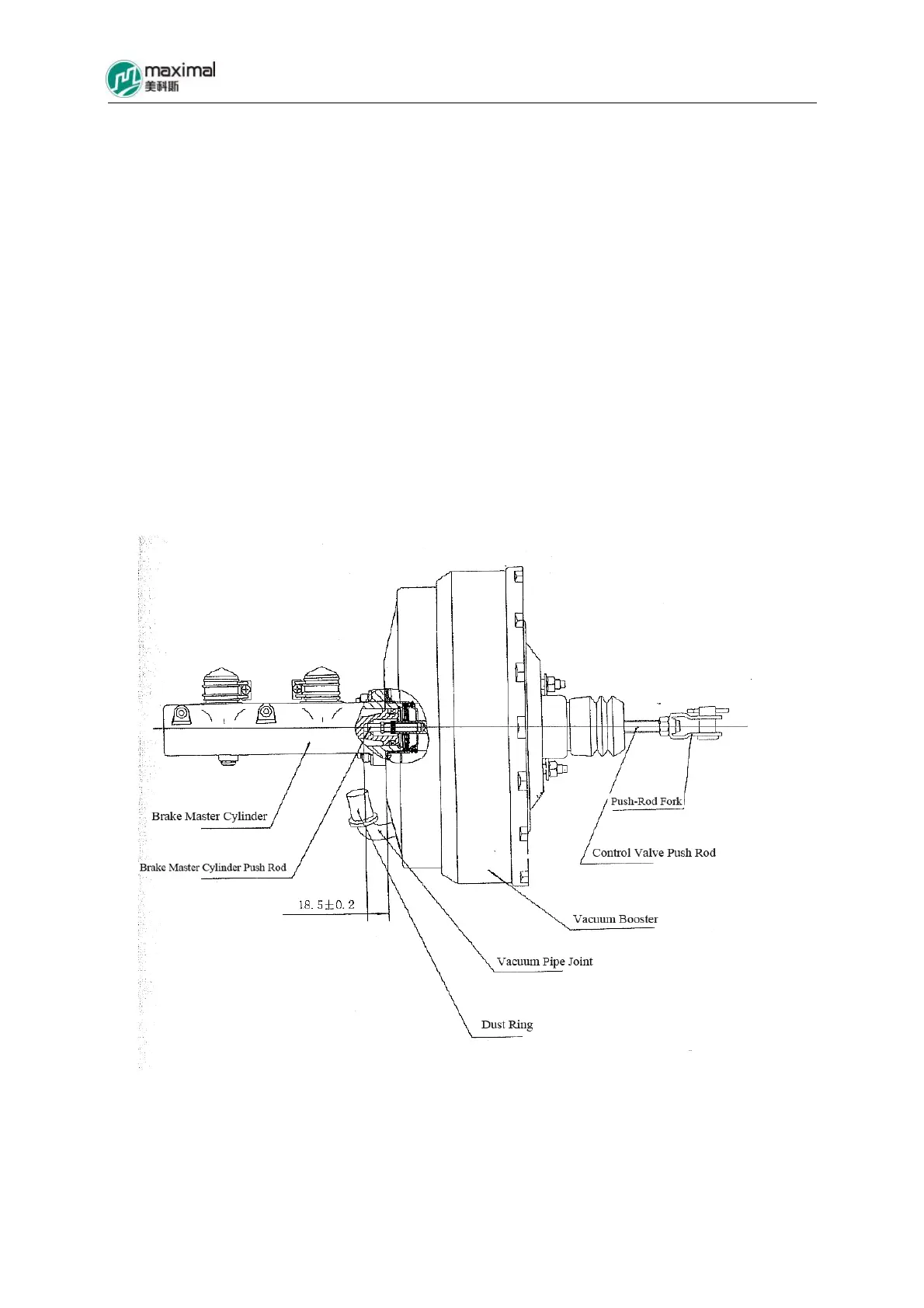

5.3.1 Vacuum Booster and Brake Master Cylinder

Refer to Fig 5-5 for the outside drawing and Fig 5-6 for the internal structure of 9’’+10’’

double-diaphragm vacuum booster and brake master cylinder used for 5-7t forklift trucks,

and the operating status of the assembly is briefly described as follows:

(1)Non-Working Status

When vacuum booster is under non-working status, the tapered large spring 3 will push

the control valve push rod 1 together with the control valve piston 5 to the limiting

position on the rear end, while the control air valve 4 is pressed tightly on part 5 by

tapered small spring, thus to close the air valve port. At this point, both front and rear

cavities of power-assisted air chamber are interlinked through the passage and the control

valve cavity with passage B, and cut off from atmosphere. When engine and vacuum

pump work, certain vacuum degrees are available in both front and rear cavities of

power-assisted air chamber.

Fig 5-5 Outside Drawing of Vacuum Booster and Brake Master Cylinder

Loading...

Loading...