5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

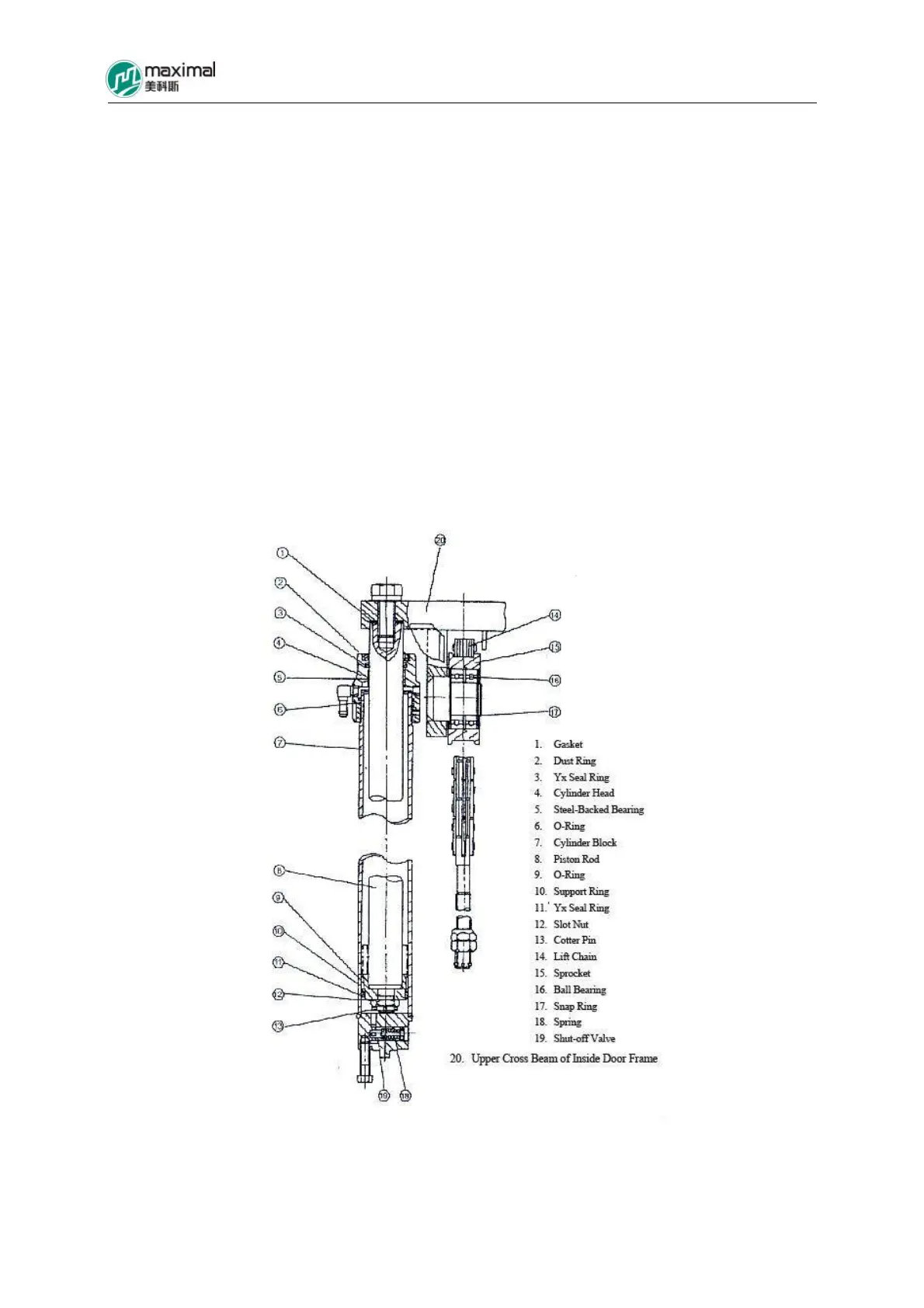

The piston and the piston rod are fixed together using slot nut, cotter pin, and o-ring, while Yx seal

ring, retainer ring, and support ring are mounted on the external circumference of the piston. For the

action of HP oil, the piston moves upward along the internal surface of the cylinder block. Dust ring

and steel-backed bearing are installed on the cylinder head that is screwed into the cylinder block

depending on thread. The steel-backed bearing is used to support piston rod, while dust ring is to

prevent the entry of dust into the cylinder. On the top of the cylinder, the tail part of the piston rod

and the upper cross beam of the inner mast are fixed using bolts.

When lift control lever is pulled backwards, the HP oil is introduced into the cylinder through the oil

inlet port of the lift cylinder and drives the piston rod and the walking beam, for the Fork to rise

through chain. When the inner mast just begins to rise, the height from the ground to the position of

Fork is called the free lifting height, and the height of mast does not change, within this range.

While the lift control lever moves forward, due to the deadweights of piston rod, Fork Carriage,

cargo stop frame, and Fork, the piston is dropped, and drain the oil under the position out of the

cylinder block. The speed of the oil drained from the cylinder block is controlled by the limiting

valve (throttle valve), and the oil returns to oil tank through multi-way valve.

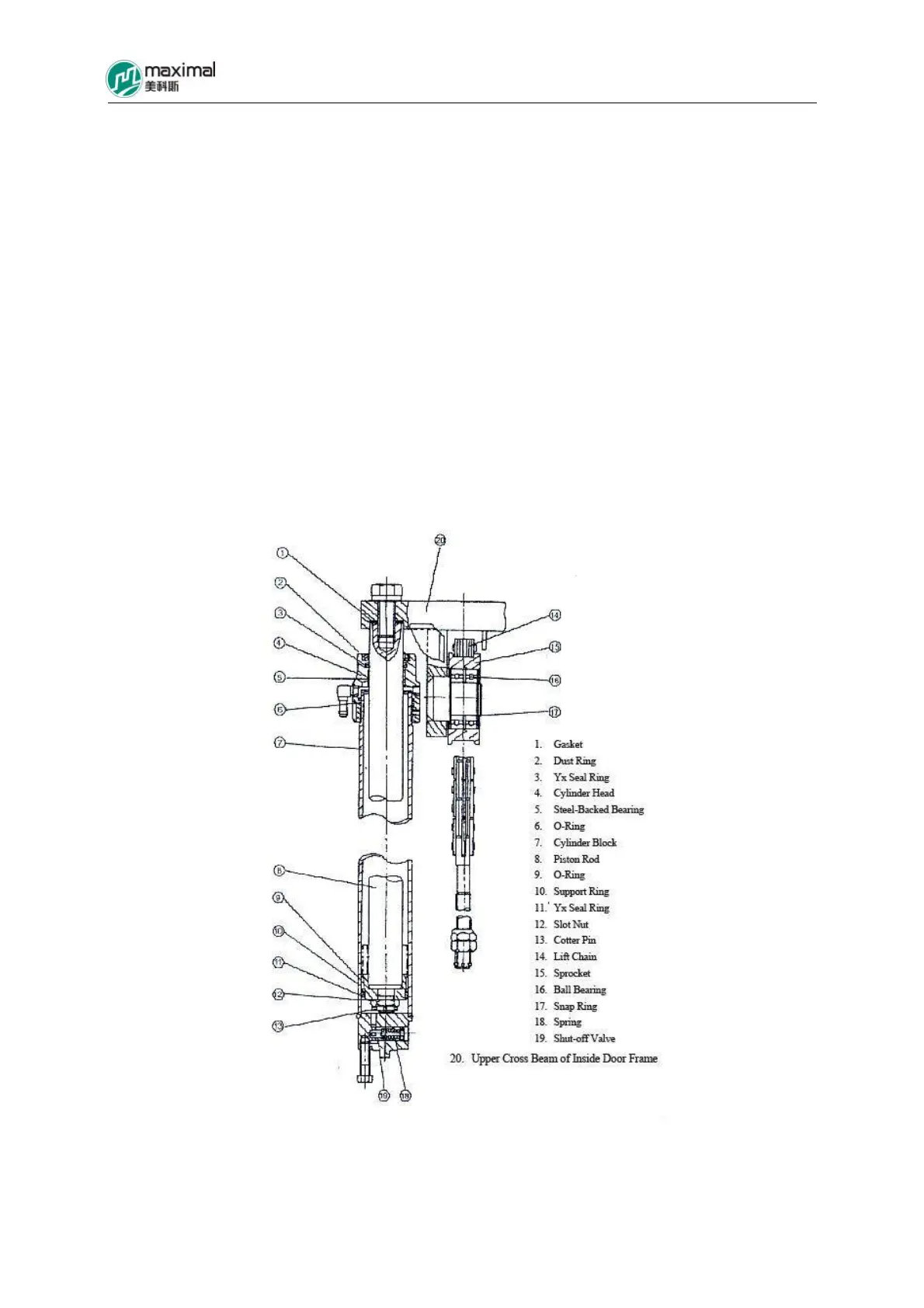

Refer to Fig 8-1 for the structure of lift cylinder for 5-8t forklift trucks. Refer to Fig 8-2 for the

structure of lift cylinder for 10t forklift truck.

Fig 8-1 Lift Cylinder (5-8t Forklift Trucks)

Loading...

Loading...