5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

(4)Fix the o-ring and the rubber cut onto the head of the slide valve, and screw down the sealing plate

using bolts, at a tightening torque of 4.6~5.8N·m.

(5)Fit in the one-way valve, spring, and o-ring into each one-plate valve, after being assembled, and

then use three connecting bolts to tighten it up according to the specified torques (103N.m for one

bolt, and 66N.m for the other).

7.10.3 Notices

The pressure for respective safety valves in multi-way valve has already been properly adjusted

before factory delivery of the forklift truck, and user shall not make adjustment at discretion during

use, to avoid damage of hydraulic system and hydraulic components due to too high pressure

adjustment. Adjust the pressure for respective safety valves correctly according to the requirements

of the manual after maintenance.

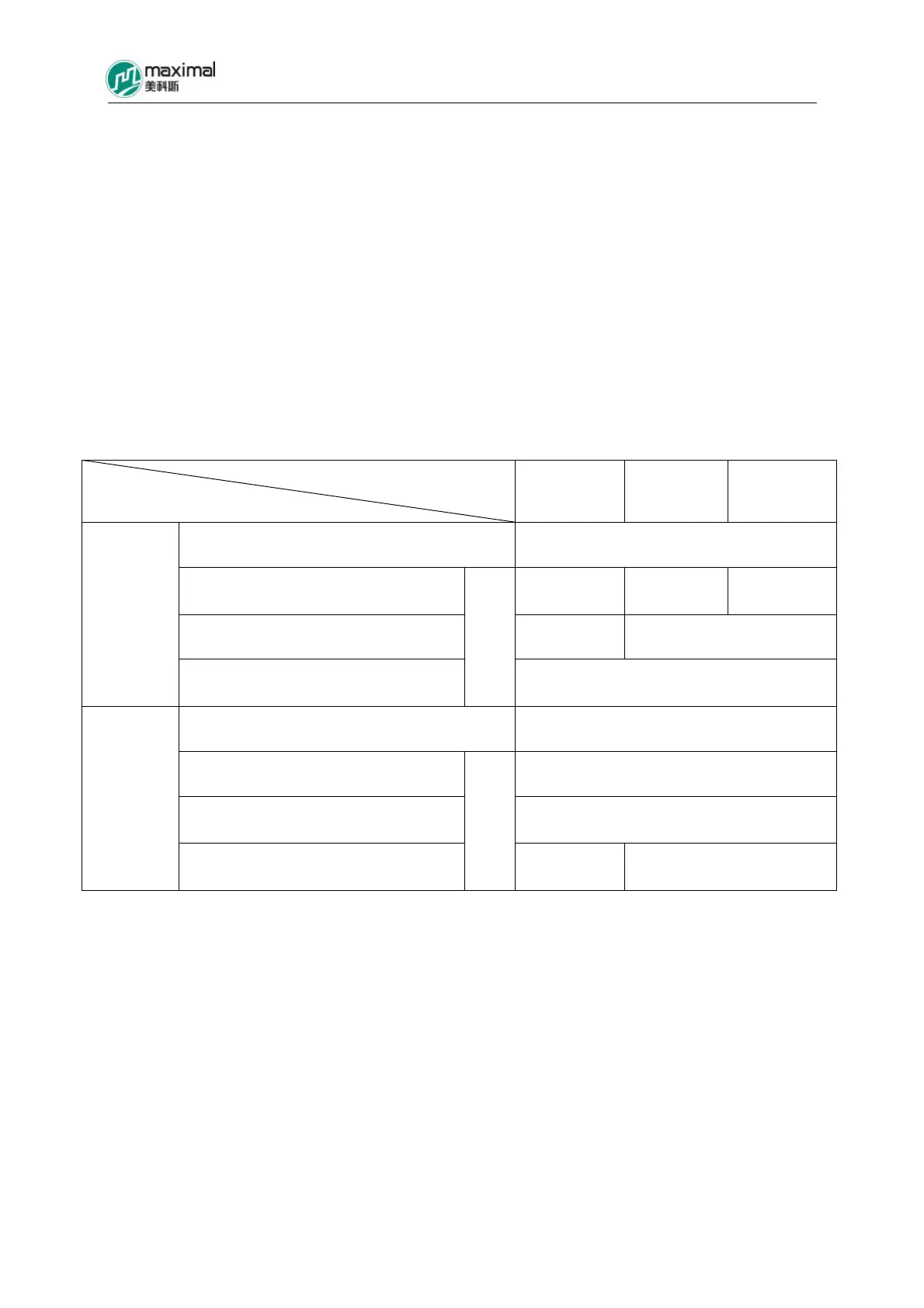

8. Lift Cylinder and Tilt Cylinder

Refer to Table 8-1 for main technical parameters.

Table 8-1

Forklift Truck Tonnage

Item

5-7t 8t 10t

Type Single-Action Piston Type

Inner Diameter of Cylinder Φ80 Φ90 Φ100

Outer Diameter of Piston Rod Φ60 Φ70

Lift Cylinder

Cylinder Stroke

㎜

1495

Type Double-Action Piston Type

Inner Diameter of Cylinder Φ115

Outer Diameter of Piston Rod Φ50

Tilt Cylinder

Cylinder Stroke(6°/12°)

㎜

227 242

8.1 Lift Cylinder

Two single-action lift cylinders are respectively fixed in the rear area of the both sides of the outer

mast. The bottom of cylinder is fixed on the bracket for the cylinder on the outer mast, while the top

part of the cylinder, or the tail part of the piston rod is connected with walking beam using bolts. The

strokes for the two lift cylinders shall be consistently adjusted, for the two cylinders to be

synchronous. They shall be adjusted through bolt if not synchronous (Refer to Fig 8-1).

The lift cylinder is mainly comprised of cylinder block, piston, piston rod, and cylinder head. There

is one oil inlet port in the lower part of the cylinder block, and the HP oil enters therefrom. In the

upper part of the cylinder block, there is an oil outlet port under the Yx seal ring of the piston, and

the LP oil is drained therefrom (The oil outlet port is connected with oil return pipe.).

Loading...

Loading...