PAGE 19

FOR SERVICE TECHNICIAN’S USE ONLY

DO NOT REMOVE OR DESTROY

8. Measure the resistance across each of the

outermost contacts and the center terminal

(ground connection).

If a resistance less than infinity is

measured, replace the sensor harness.

9. If the moisture sensor diagnostic test

passes, check the outlet thermistor: TEST #4a,

page 15.

If the problem persists after replacing the

moisture sensor and thermistor, consider

adjusting the dryness level (see TEST #5a:

Adjusting Customer-Focused Dryness Level).

10. If the preceding steps did not correct the

problem, replace the CCU.

TEST #5a: Adjusting Customer-

Focused Dryness Level

NOTE: If the customer complains about the

clothes being damp and the moisture sensor

passes TEST #5: Moisture Sensor, step 3, the

total dry time can be lengthened (or shortened)

by changing the factory preset dryness setting.

1. Turn the cycle selector knob to an

automatic cycle.

2. From the Automatic Cycle Main Screen,

press and hold the dryness level button

(~3 seconds) until the “custom dryness

level” screen appears.

3. Select the desired dryness setting:

“factory preset” (standard auto cycle),

“15% More”, “30% More, “15% Less”, or

“30% Less”. The following screen will confirm

your selection. The selection will be stored on

the CCU and will be retained—even after a

power loss.

NOTE: If dryness setting is not selected within

6 seconds, it will time out and exit to the Main

Screen.

TEST #6: User Interface (UI)

This test is performed when any of the

following situations occurs during the “Service

Diagnostics ➔ Component Activation ➔ UI

Component Test.” (See page 5.)

3None of the indicators or display turn on

3Some buttons do not light indicators

3No beep sound is heard

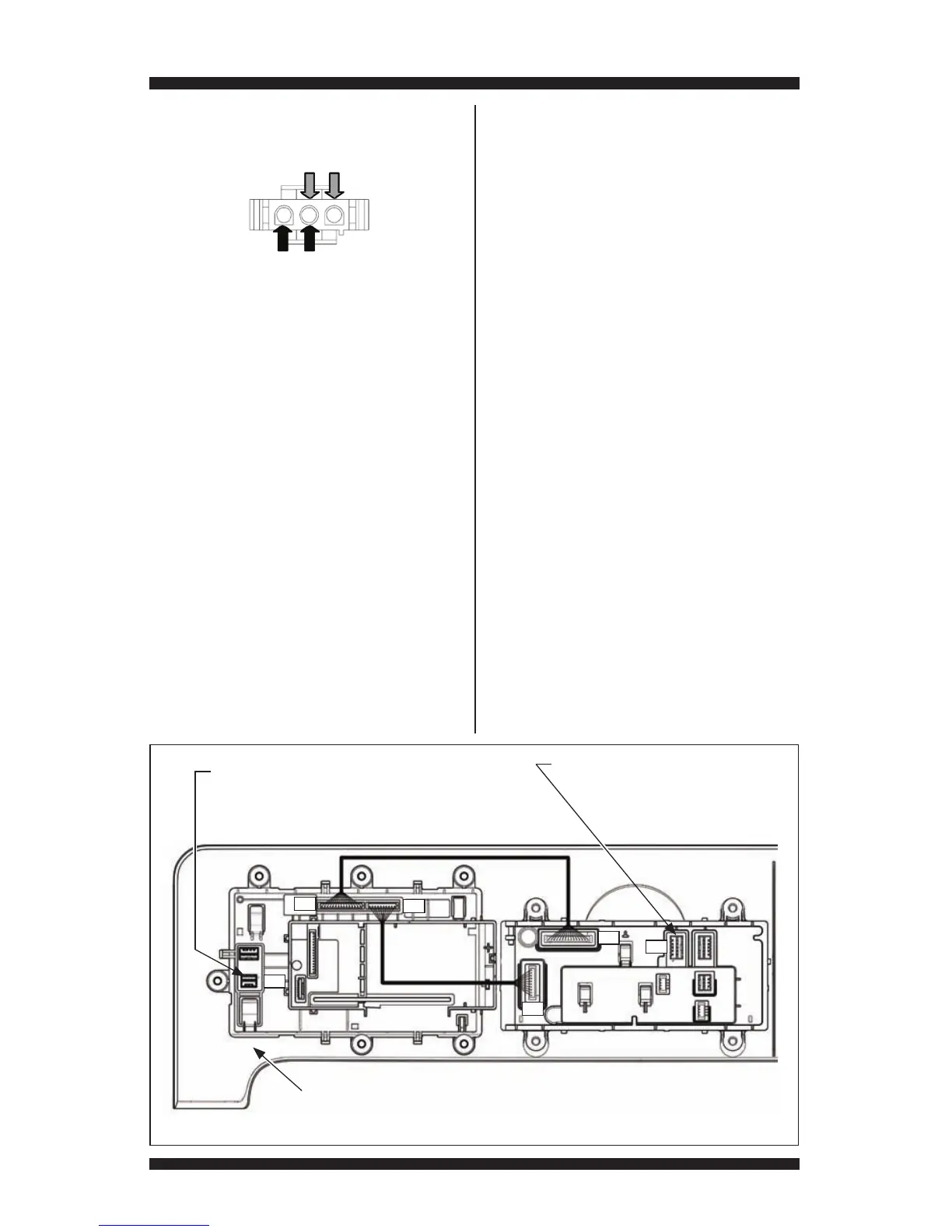

NOTE: The User Interface, which includes the

Console, Modifier, and Center PCBs, must be

diagnosed and replaced as a single component.

None of the indicators or display turn on:

1. Unplug dryer or disconnect power.

2. Remove top panel to access the CCU.

3. Visually check that ALL CCU connectors

are fully inserted into the CCU (see page 9).

Figure 22 - User Interface (UI)

P07

P06

P02

P08

P09

P13

Center PCB

Console Assembly

P02 (from CCU):

Pin 1: Open

Pin 2: Ground

Pin 3: Data (WIDE BUS)

Pin 4: (+5V)

Pin 5: Open

P13 (to Drum Light):

See TEST #8: Drum Light, page 20.

Pin 1: Drum_L_P

Pin 2: Open

Pin 3: Drum_L_N

NOTE:

The User Interface (UI) must be replaced

as a single assembly. The UI includes the

Console, Modifier, and Center PCBs.

Modifier

PCB

Loading...

Loading...