19

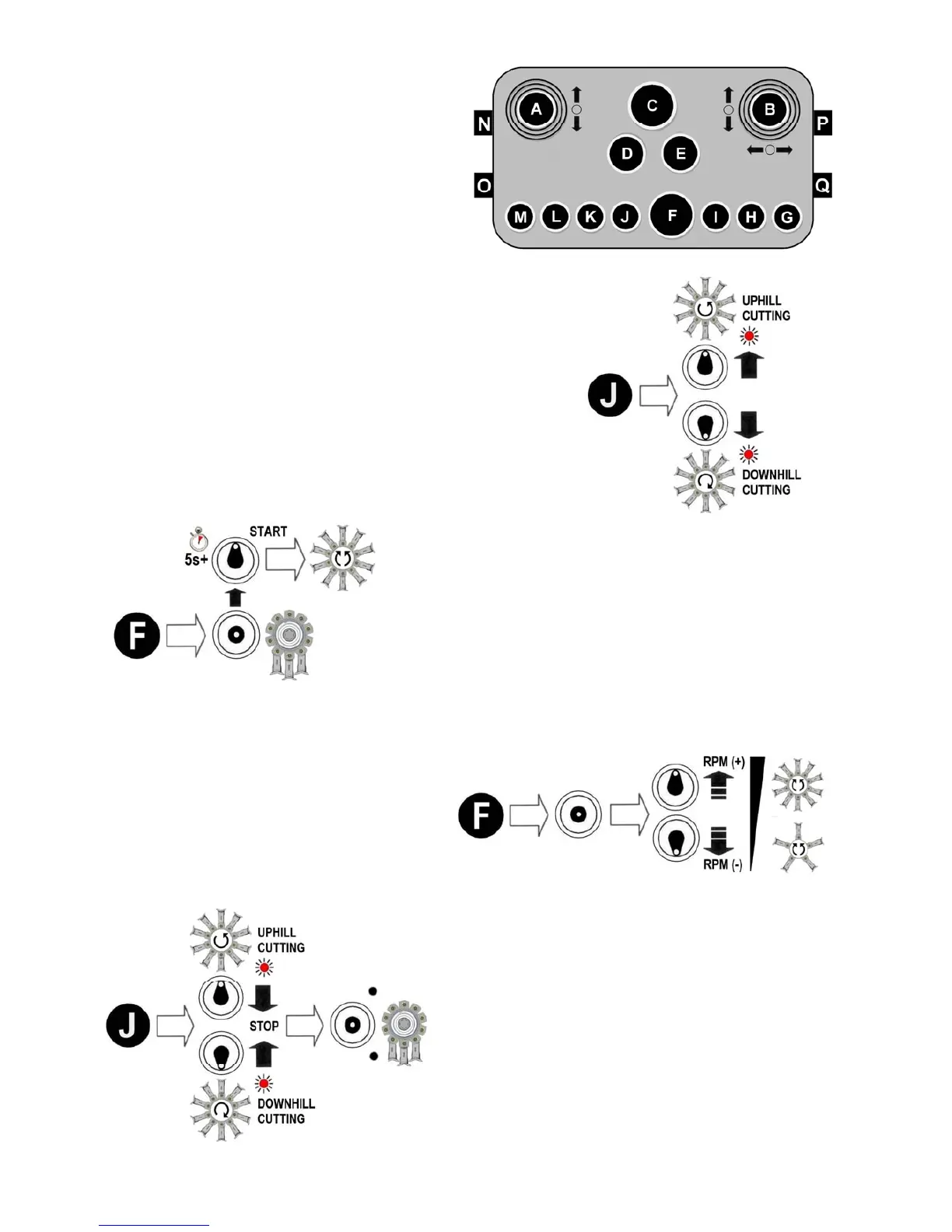

Flail Head Rotor Controls

Operation of the rotor is controlled by using

switches ‘J & ‘F ’. Each of the switch es

performs a dual function; switch ‘J’ is for pre-

setting the rotor cutting direction and for

switching the rotor off, and switch ‘F’ is for

starting the rotor and adjusting its speed.

Refer below for specific details of each

function.

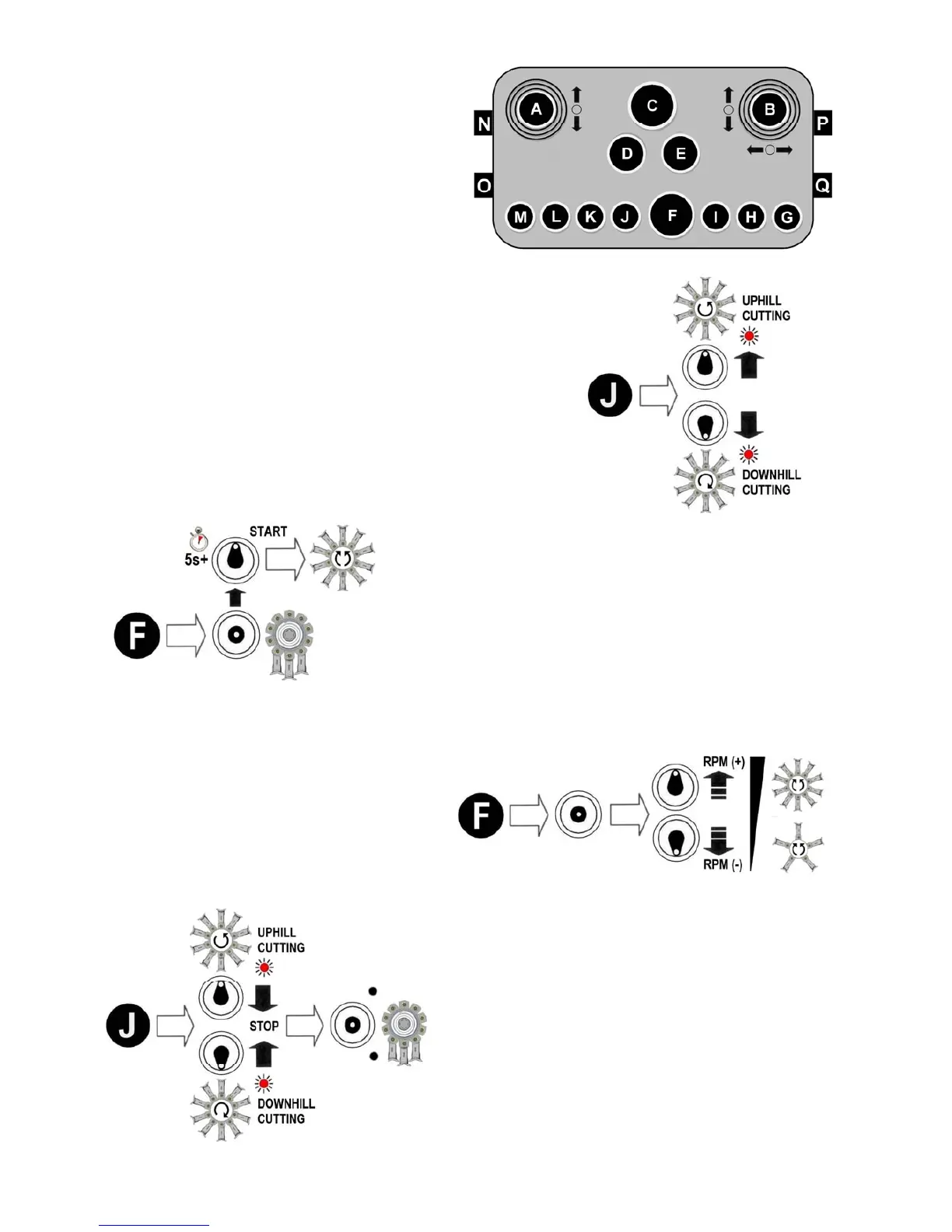

Selection of Rotor Cutting Direction ►

Switch ‘J ’ is for pre-selection of the rotor cutting direction;

move the switch to the up posit ion for uphill cutting or to th e

down posit ion for downhill cutti ng - an led light will be

illuminated to indicate the di rection selected. Starting the

rotor is performed by operation of switch ‘F’ – see below.

◄ Rotor Start

Starting the rotor is by operatio n of switch ‘F’; set engine

speed to run at minimum revs before pressi ng the switch

upwards – the switch has a built in time delay to a void

unintentional rotor operation and must be held in pos ition

for at least 5 seconds ; release the switch as soon as the

rotor starts to run. Engine revs can now be increas ed

according to requirements.

Rotor Speed (RPM) ►

Once the rotor is running its speed can be

increased or decreased as required by

subsequent operations of switch ‘F’; eac h

upward or downwar d operation of the

switch will respective ly speed up or slow

down the rotor by a determined amount.

◄ Rotor Stop

To stop the rotor, first reduce the rotor speed to its

minimum using switch ‘F’ as des cribed above, then

move Switch ‘J’ into the central ‘off’ position.

Note (Pre-June 2015 machines only);

In an emergency situation the rotor can be stopped

by use of the Emergency Stop Button ‘C’; this will

immediately switch off and deactivate all machine

functions completely, including the engine.

This feature is not applicable to later machines.

Loading...

Loading...