42

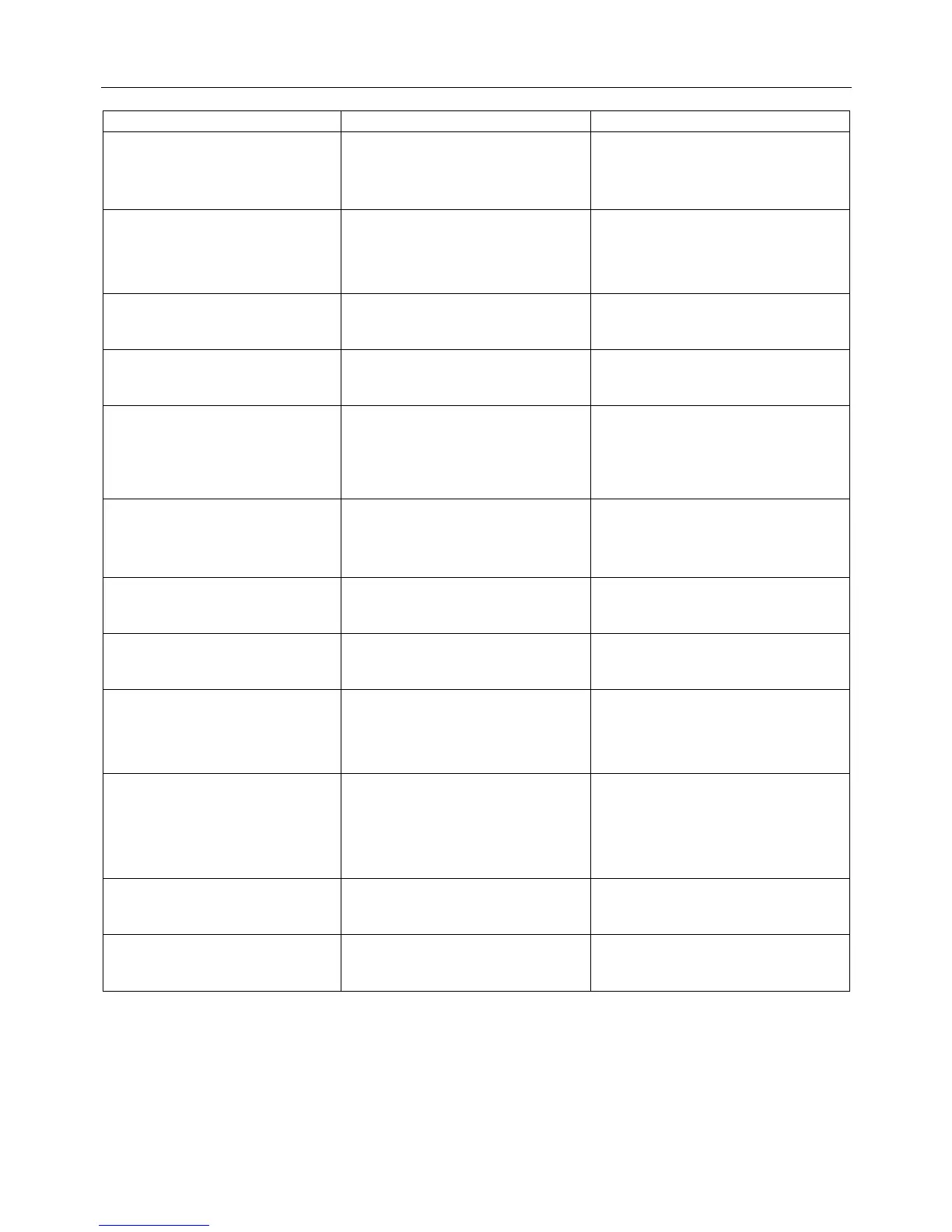

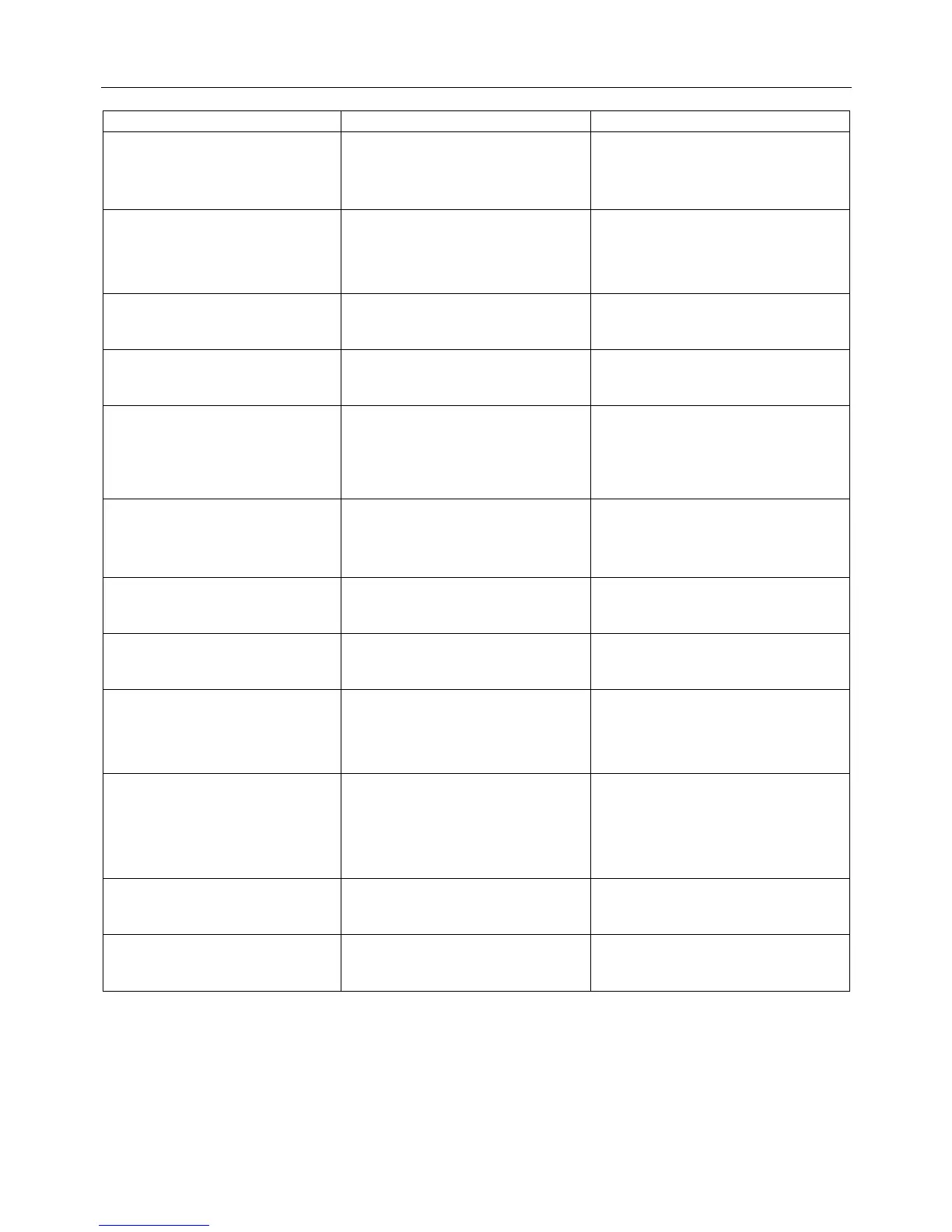

TROUBLESHOOTING

Symptom Possible Cause Solution

Track damage. Excessive tread wear;

Loosening/breaking of internal

structural steel rope.

Replace track.

Track slackens frequently. Faulty tensioner valve.

Damaged tensioner seal.

Worn tensioner components.

Replace valve.

Replace seal.

Replace worn components.

Upper track does not stay in

position.

Track slide worn.

Upper roller worn.

Replace slide.

Replace upper roller.

Lower track does not stay in

position.

Lower track guide worn.

Lower roller worn.

Replace lower track guide.

Replace lower roller.

Track ‘jams’ when the machine

is steering.

Material (stones, rocks, earth

etc.) trapped between rollers,

sprockets, idler roller and track.

Remove material by turning the

track in both directions while

slackening slightly, raise machine

at same time if possible.

Oil leakage Hardened seals.

Gasket/seals damaged or worn.

Clean around component and

recheck after a few days.

Contact dealer.

Excessive noise. Internal malfunction.

Worn seals.

Contact dealer.

Excessive vibration. Internal malfunction.

Worn seals.

Contact dealer.

Overheating Lack of oil.

Arduous conditions/hot climate.

Brakes binding.

Add oil.

Contact dealer.

Check brake release pressure.

Motor runs but gear unit not

working.

Motor wrongly assembled.

Internal malfunction.

Brake jammed.

Check coupling between motor

and gear unit.

Contact dealer.

Check braking system.

Brake not releasing. Lack of brake pressure.

Faulty brake seals.

Check brake connections.

Contact dealer.

Brakes not locking. Residual pressure in circuit.

Worn brake components.

Check hydraulic system.

Contact dealer.

Loading...

Loading...