20

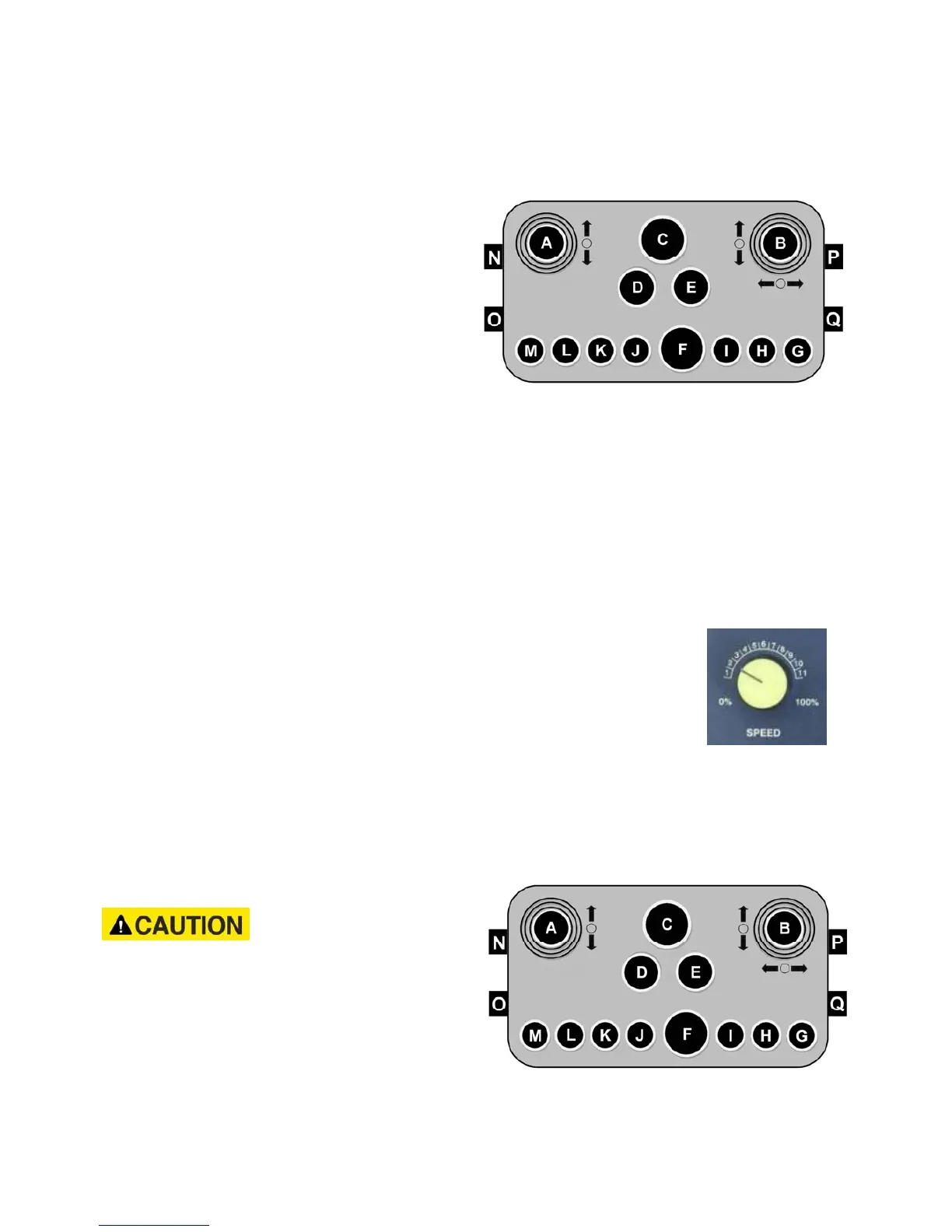

Flail Hood Control (Machines Operating with Flailhead Attachment)

The flail head is equipped with hydraulically operated front hood allowing the operator to

remotely adjust its opening position to suit differing materials and conditions. The hood, which is

powered by a hydraulic ram, is controlled by up and down operation of switch ‘I’; the switch is

self-centering so operation of the hood in either direction only occurs when the switch is held in

the up or down ‘on’ positions, on release of the switch hood operation stops.

Engine Speed Control (RPM)

The speed of the engine is adjusted using control buttons ‘P’ and ‘Q’; pressing button ‘P’ will

increase engine revs and pressing button ‘Q’ will decrease the revs.

Gear Control

The machine has 2 gears to provide a choice of travel speeds; in addition to the gear selected

the travel speed will be managed by operation of the travel joystick which itself is directly

proportional to the speed setting of the potentiometer – see below.

When in work it is recommended that the machine is operated in gear 1 and speed limited

especially when working on steep slopes. Gear 2 is primarily for use when driving the machine

between work areas on smooth even terrain where it is safe to use higher speed.

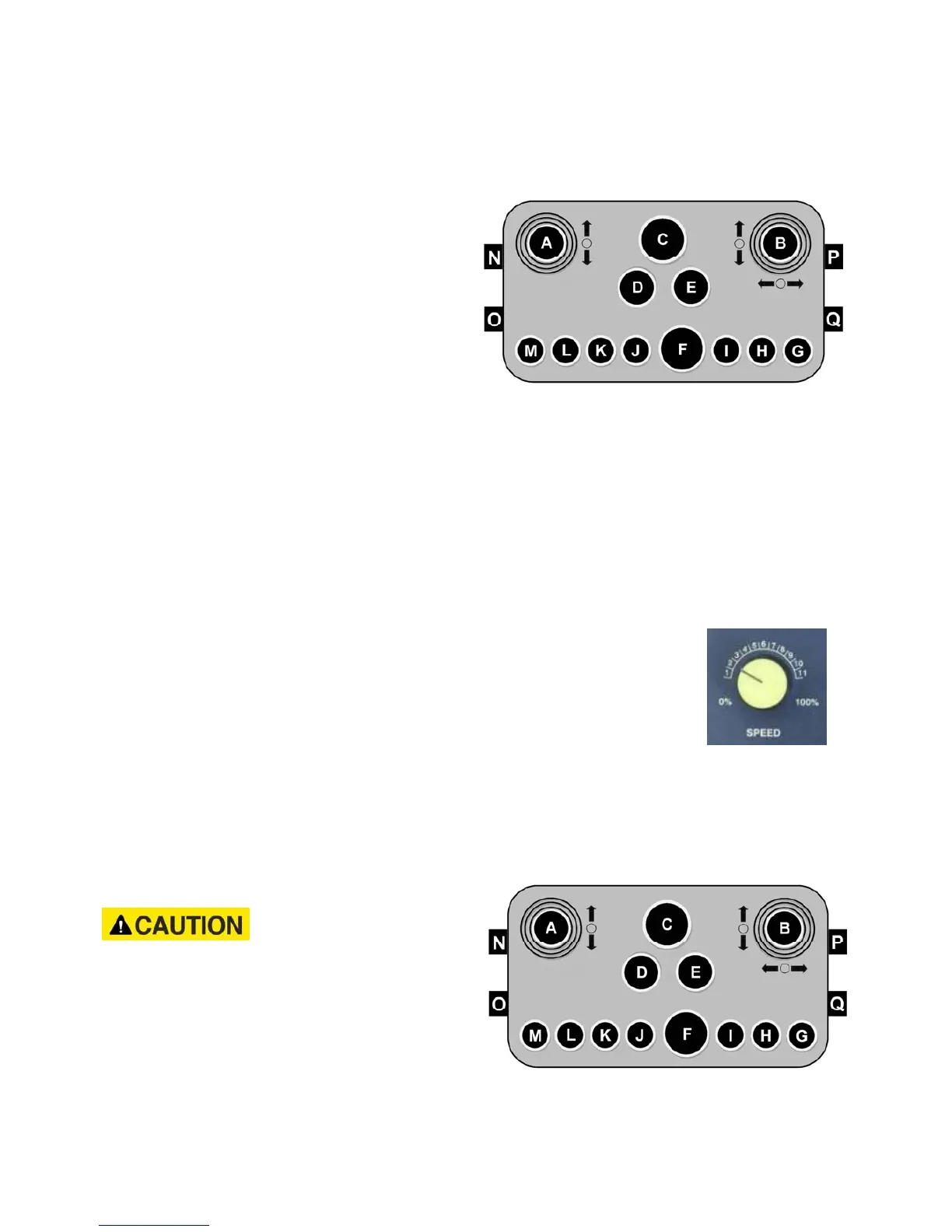

Potentiometer

The potentiometer control (rotational switch ‘D’) determines the maximum

travel speed capability of the machine, from 0 – 100%, when operating the

travel joystick - it is in effect an adjustable speed governor.

Adjustment is by rotating the switch to the required speed (%) position; the

setting chosen will depend on numerous factors but should always be at a

setting that allows the operator optimum control of the machine in work.

Engine Shutdown

Before shutting down the engine all machine movements must be halted, engine revs reduced

to minimum and the rotor switched off. Allow the machine to run at this level for about 1 minute

to stabilize pressures and temperatures - shutting down the engine is then performed by

pressing button ‘N’ which will stall the engine. When the engine has stopped the procedure is

completed by switching off the ignition key on

the machine.

Always turn ignition key OFF after stopping the

engine; failure to observe this risks possible fuel

pump damage due to electric pump overheating.

If the machine is to be left unattended the key

should be removed and control unit and key

placed in a secure safe location.

Engine Start

Engine start from the remote control unit is by use of button ‘O’ – refer to ‘Starting Engine’

section for details of this procedure.

Loading...

Loading...