29

Maintenance Scheme (Track Components)

Daily Checks

Check track tension.

Check condition of gear motors.

Check track condition; replace tracks when there is less than 10mm of tread remaining or

sooner if there are visible signs of deep cuts or cracks.

Check there are no stones or foreign bodies within the tracks, rollers, gears or sprockets.

Monthly Checks

Check oil level in gear unit.

Check rollers are correctly fastened.

Check there is no slack in the bearings.

Six Monthly Checks

Check wear and tear and overall condition of connections, pinions and lower rollers – these

must be replaced when they reach their maximum wear limit; refer to ‘wear limits’ page.

Check brakes are working correctly.

Check all nuts and bolts for tightness.

Periodic Checks

Check brakes and safety warning decals are in good condition.

Make sure the machine is thoroughly cleaned on a regular basis.

Check all fastenings, supports, steel structural parts, welds and pins etc. are in good condition.

Ensure paintwork is kept in good condition.

Lubricate the tracked undercarriage every 20 working hours.

Hydraulic Hoses

Hoses and hydraulic connections should be inspected for signs of wear or damage on a regular

basis, damaged or worn components must be replaced immediately. The working life of

undamaged hoses is approximately six years, they should be replaced after this period.

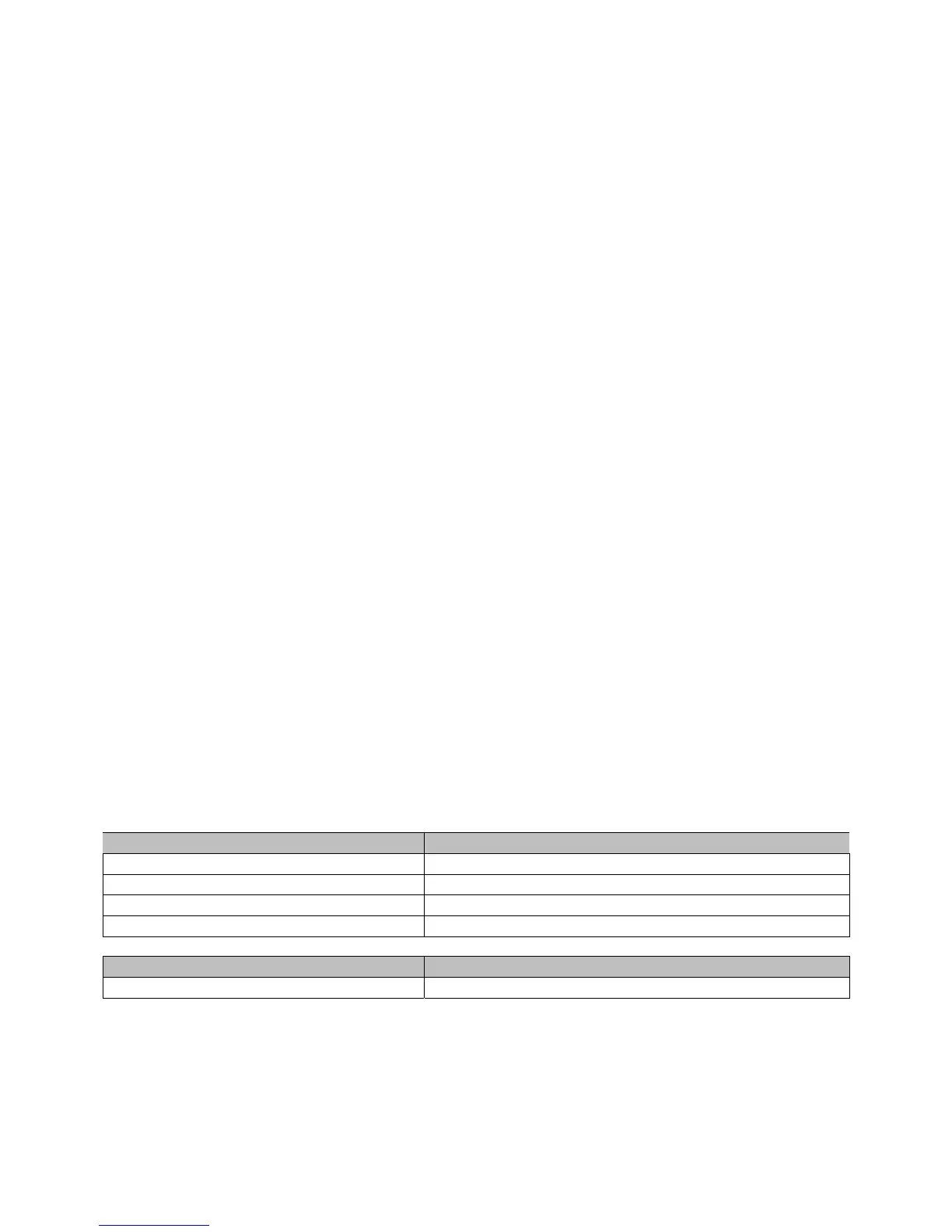

Recommended Lubricants / Coolant

Always use the recommended lubricants/coolants taken from the chart below or a good quality

equivalent product.

Machine Component Recommended Lubricant

Hydraulic System (Biodegradable) PANOLIN HLP SYNTH E 46

Hydraulic System (Mineral) Q8 ELI 1298 L

Engine MOBIL SUPER 3000 X1 5W-40

Pins / Bushes / Bearings GREENPLEX EP GREASE

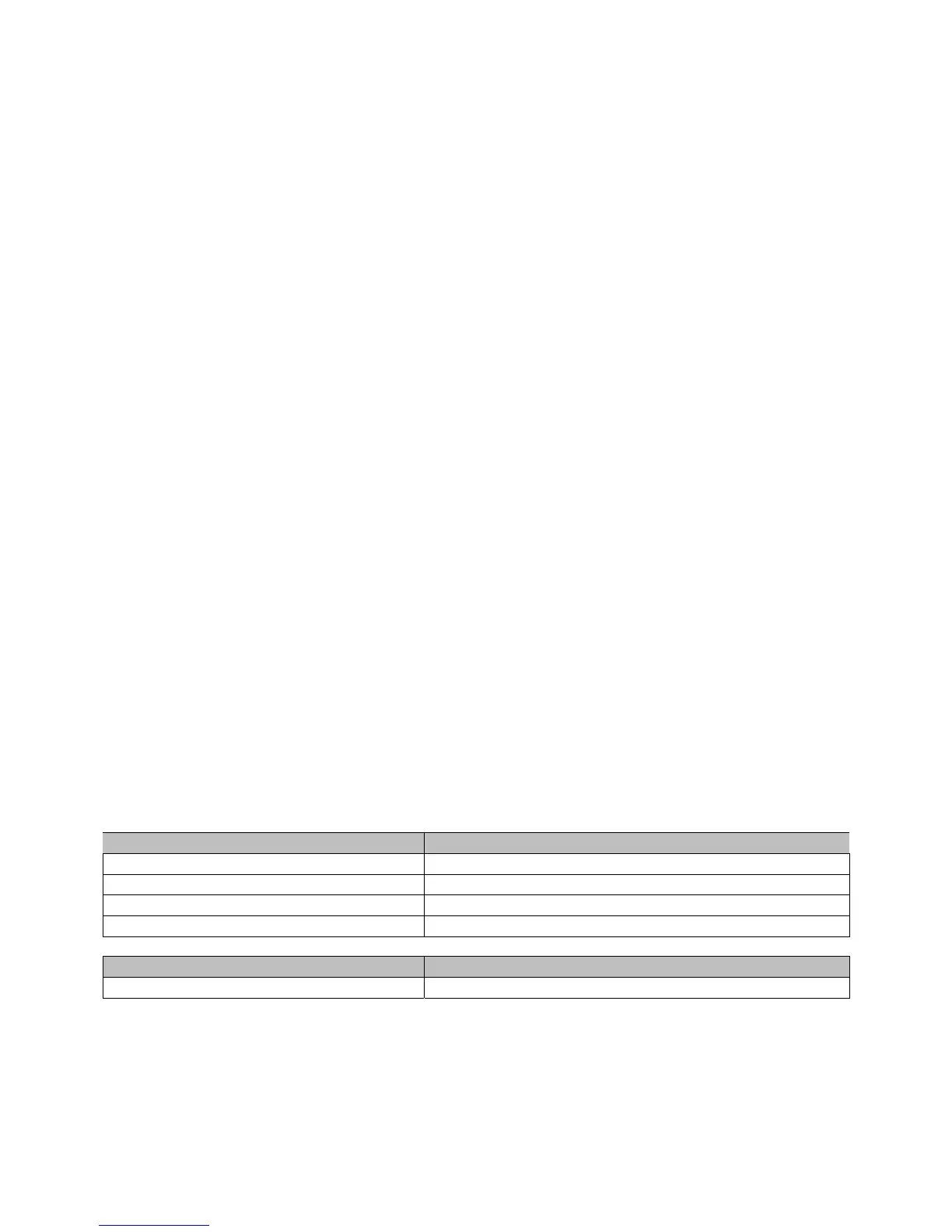

Machine Component Recommended Coolant

Cooling System PERMENANT SUPER ANTIFREEZE LF (50% Dilution)

Loading...

Loading...