38

Replacing Tracks

Tracks must be changed when only 10mm of tread remains, or before if they show signs of

excessive cuts or cracks.

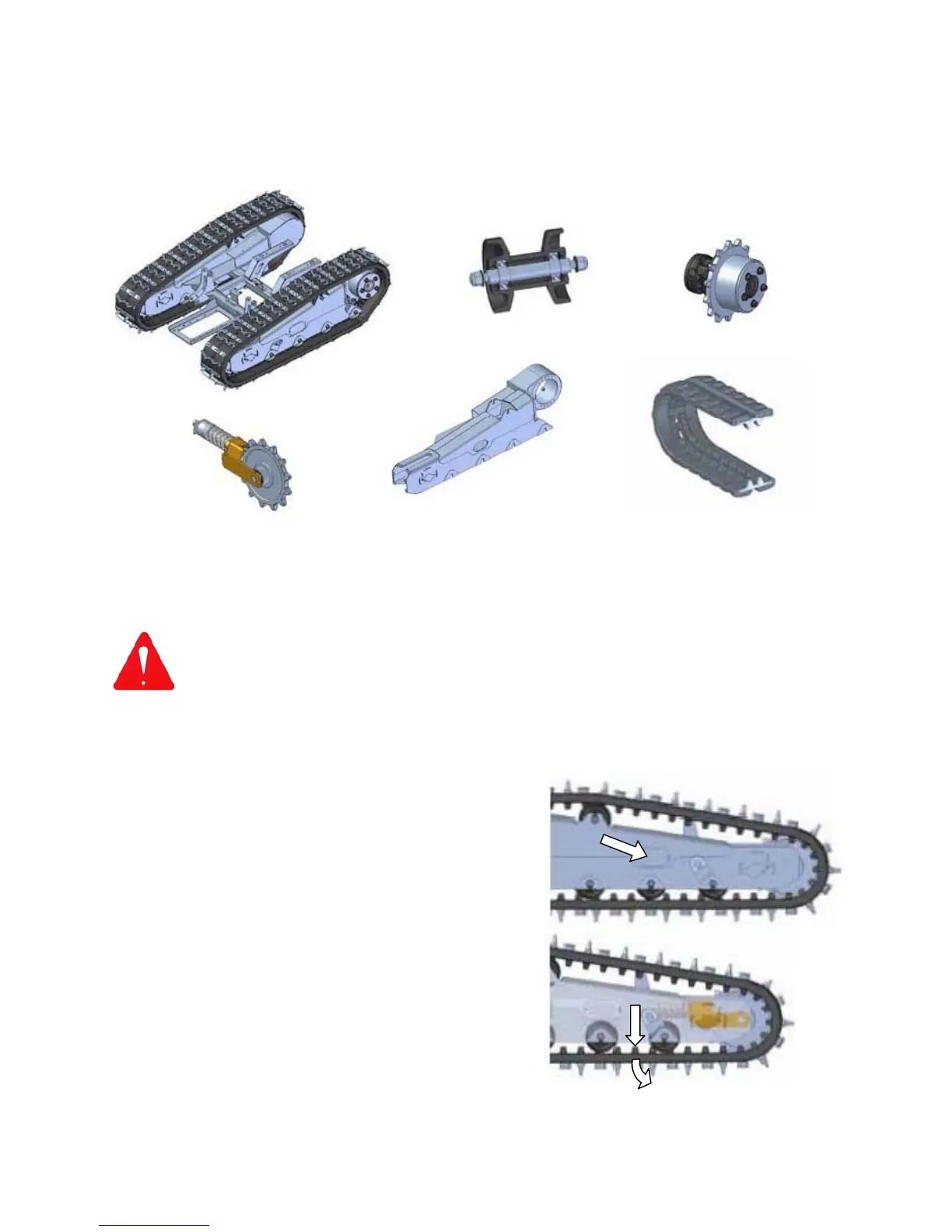

The components shown below are constituent parts of the track system illustrated here for

identification purposes.

The procedure for changing the tracks is as follows;

WARNING: Never attempt to work on any machine that it not safely supported and chocked using

suitable equipment specifically designed for the task and capable of supporting its

weight. Ensure suitable safety gear is worn at all times when performing maintenance

tasks. Beware, there is ‘pinch risk’ when working on these components.

Raise the machine off the ground to a height of approximately 30-40cm; ensure the machine

is stable and suitably supported.

Clean undercarriage components and their surrounding area prior to performing

maintenance on them.

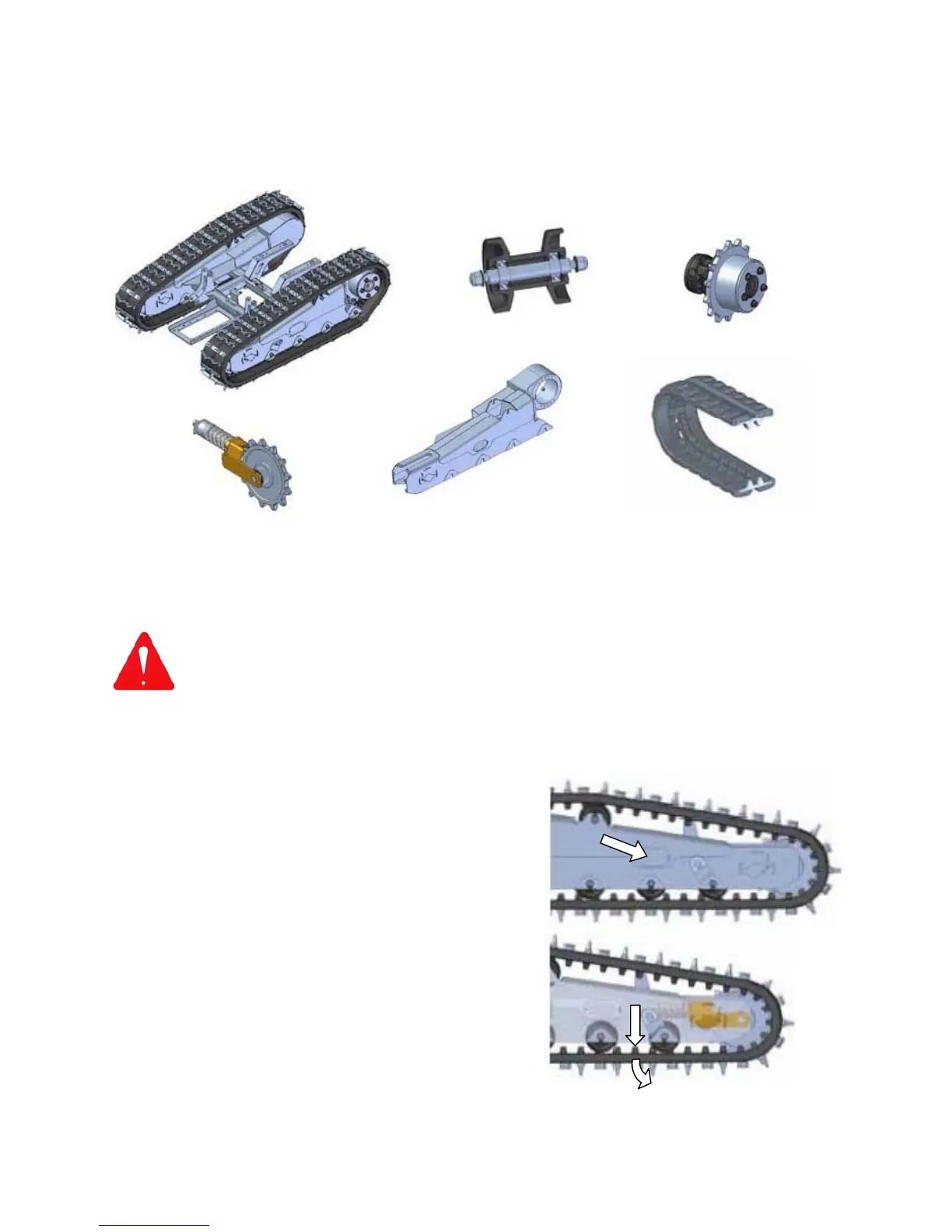

Remove backstay side cover ►

Loosen valve on the tensioner unit to release the

grease pressure.

Once pressure has been fully released the valve

can be removed.

Compress the idler roller; this can be done by using

your foot to press the track back.

Draw the track down and outwards at its mid point

on the lower run to pull it off its seating, levering

between the track and the idler roller until it is free

enough to be removed. Take care to keep clear of

the track as it falls to the ground.

Installing the new track is basically a reversal of the above – tension the track by pumping

grease into the tensioner unit to a pressure of 130 Bar. (Max. 150 Bar).

Lower Roller Unit

Sprocket Assembly

Tracked Undercarriage

Backstay

Idler Roller Rubber Track

Loading...

Loading...