39

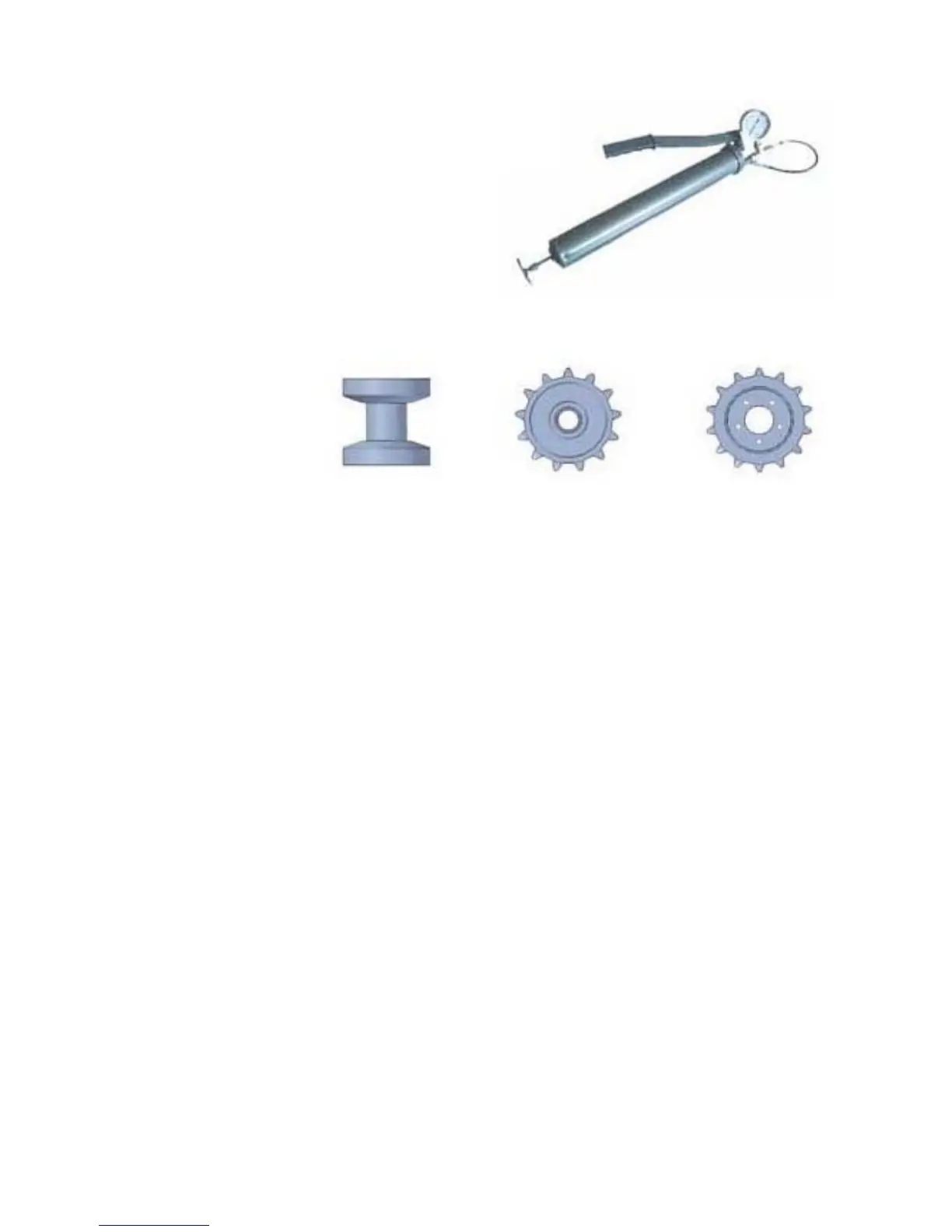

Lower Rollers Front Cogs Drive Cogs

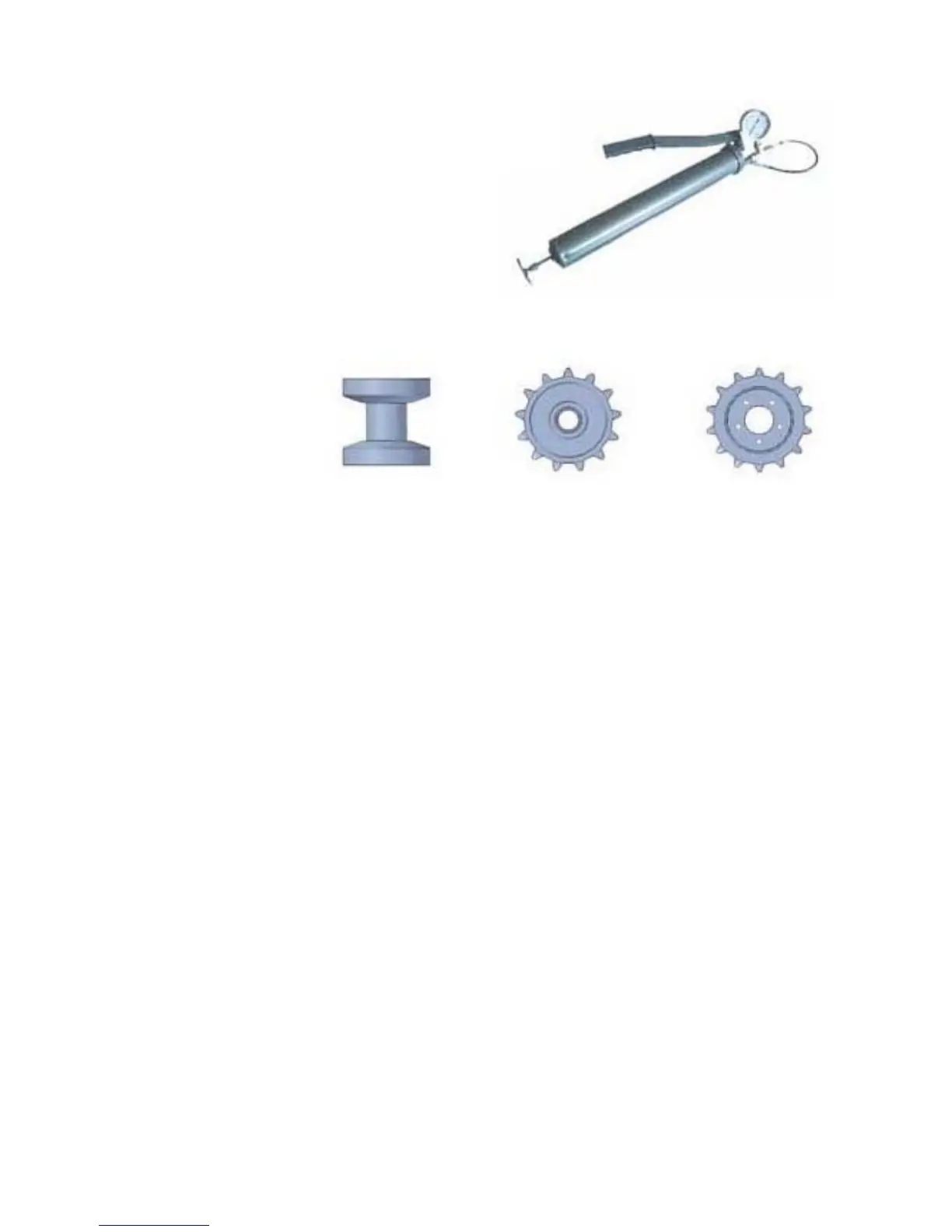

Track Tension Kit (4000271)

Track Tension Kit (Optional)

A grease tensioner system controls the track

tension on the machine. Keeping the tracks

correctly tensioned is an important duty that must

be carried out at the intervals stated in the

maintenance schedule; failure to observe the

correct tension can result in the tracks coming off

the machine during operations.

A Tension Kit, comprising of a grease pump

equipped with a manometer, is available as an

option for use in correctly checking and setting

the pressure. The correct pressure is 130 Bar.

(Max. 150 Bar).

Wear Limits

The track components

shown opposite must be

replaced when they reach

their maximum wear limit,

corresponding to 100% in

the figures stated below;

Ø when new ►

130.0mm 264.0mm 290.0mm

Ø at 25% wear ►

128.0mm 263.0mm 289.0mm

Ø at 50% wear ►

126.0mm 261.5mm 287.5mm

Ø at 75% wear ►

124.0mm 259.5mm 285.5mm

Ø at 100% wear ►

121.0mm 257.0mm 283.0mm

Lubrication of Undercarriage Components

Components of the tracked undercarriage (rollers, pins, bushings etc.), must be greased every

20 working hours.

Loading...

Loading...