3 - 3

Operation

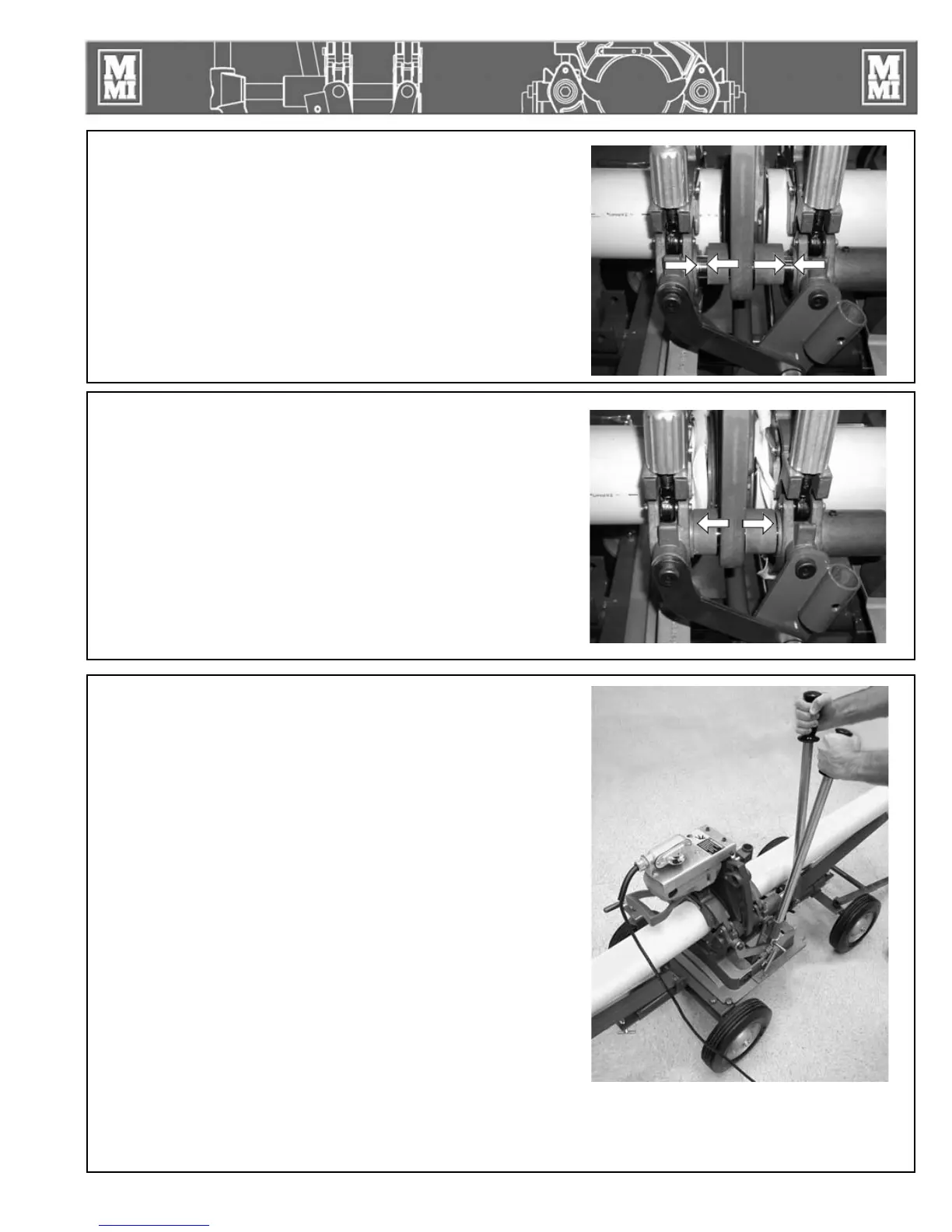

Positioning Pipe in Machine

Position the facer on the guide rods and lock into position. Using

lever handle, bring pipe ends together against the facer, watching

the gap between the facer stops and the pipe clamping jaws. Leave

enough gap so that proper face-off will be achieved when the facer

stops are bottomed out against the clamps. Tighten the pipe clamp

knobs by hand until firm resistance is felt. Do not over-tighten.

NOTICE: Thoroughly clean all dirt and debris from pipe ends before

facing.

TX00839-1-5-96

Facing the Pipe Manually

Turn facer handle counterclockwise and apply firm pressure on lever

handle. Continue facing until facer stops have bottomed out against

the clamping jaws. Stop rotation of facer. Move jaws apart.

Unlatch and remove facer. Remove shavings from pipe ends and

machine. Do not touch faced pipe ends.

Inspect both pipe ends for complete face off. If the face off is

incomplete, return to Loading Pipe Into Machine.

TX01848-7-25-00

PH01870-7-25-00PH001869-7-25-00

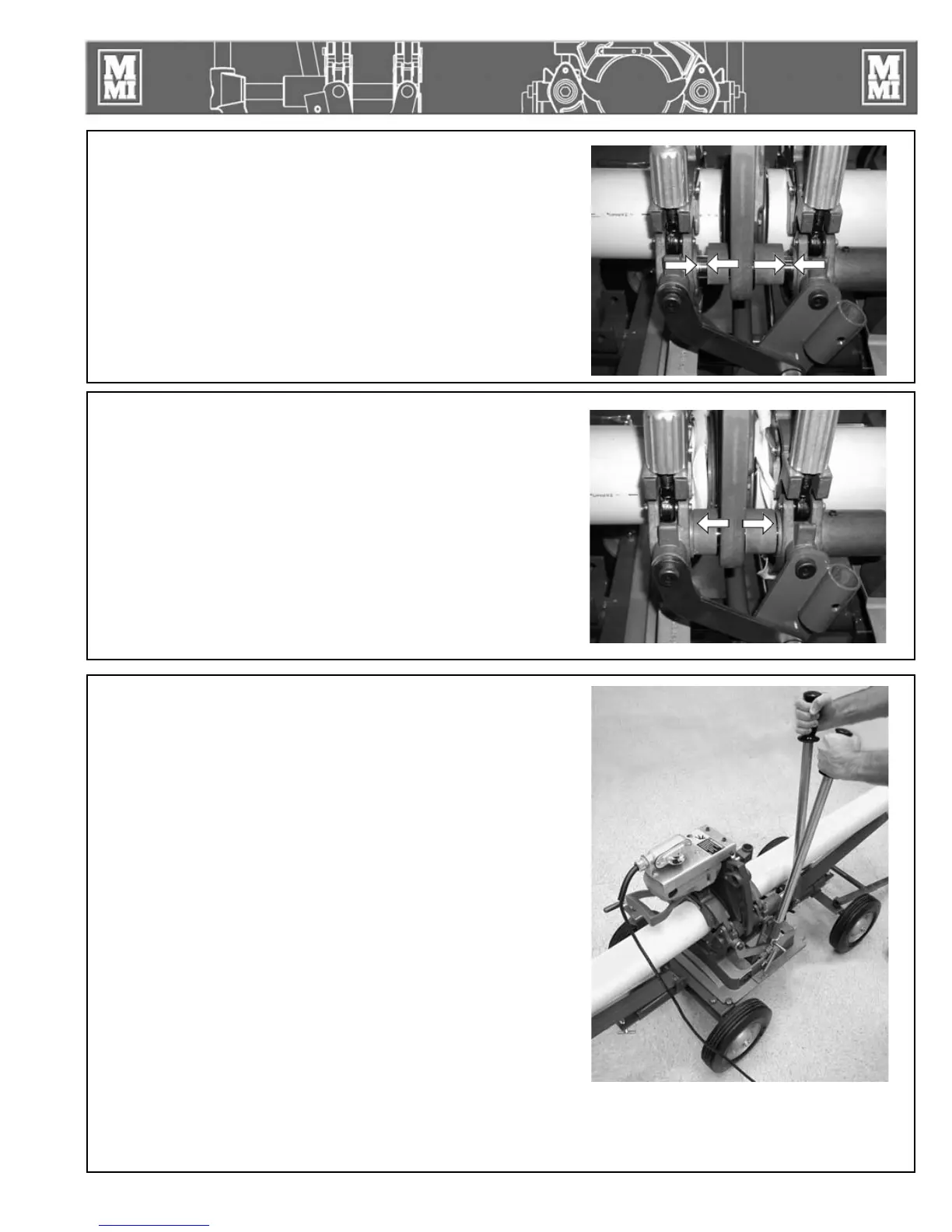

Electric Facer

The electric facer should be started before the pipe is pushed into

contact with the blades. Continue facing until the facer stops are

against the jaws then turn off the facer while continuing to hold

pressure closed on the lever until the facer stops completely.

Reverse force to the lever handle to move the pipe ends away

from the facer. Unlatch and remove the facer taking care not

to touch the pipe ends. Remove shavings from pipe ends and

machine. Do not touch faced pipe ends as this may contaminate

them.

If after facing any imperfections are visible on the ends of the pipe

move the pipe inward and reface.

Any time clamp knobs are tightened pipe ends should be refaced.

TX01851-7-25-00

PH01886-7-25-00

Loading...

Loading...