3 - 2

Machine Setup

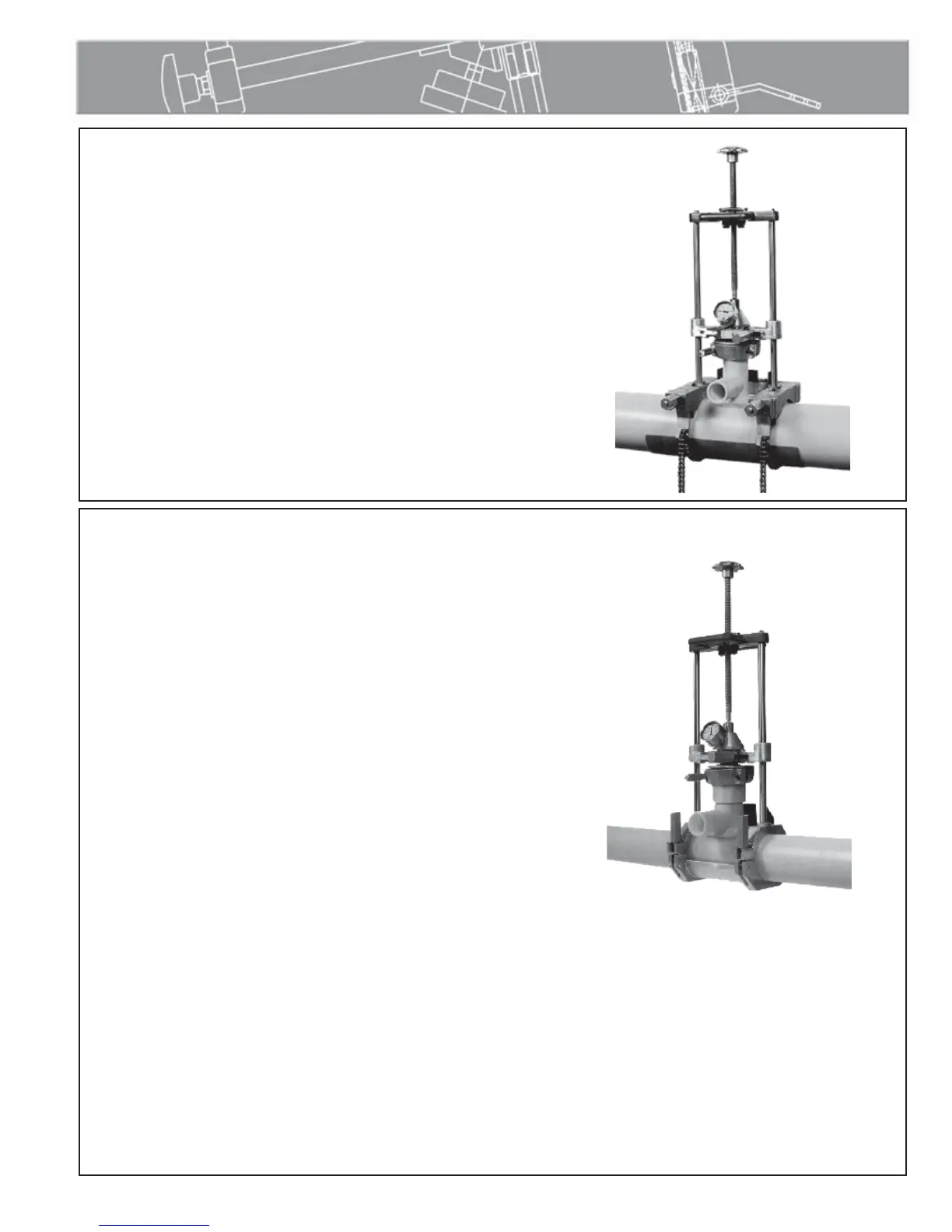

Chain Clamp Procedure

Loosen the sidewall clamp knobs and remove the chains from the

chain hooks.

Place the Sidewinder on the pipe in the desired vertical or

horizontal position. Center the line bolster on the pipe opposite

the Sidewinder.

Bring the chains around the pipe and bolster and lock in the

chain hooks. Tighten the sidewall clamp knobs until the pipe

conforms to the clamping inserts and line bolster.

TX00905-6-21-10

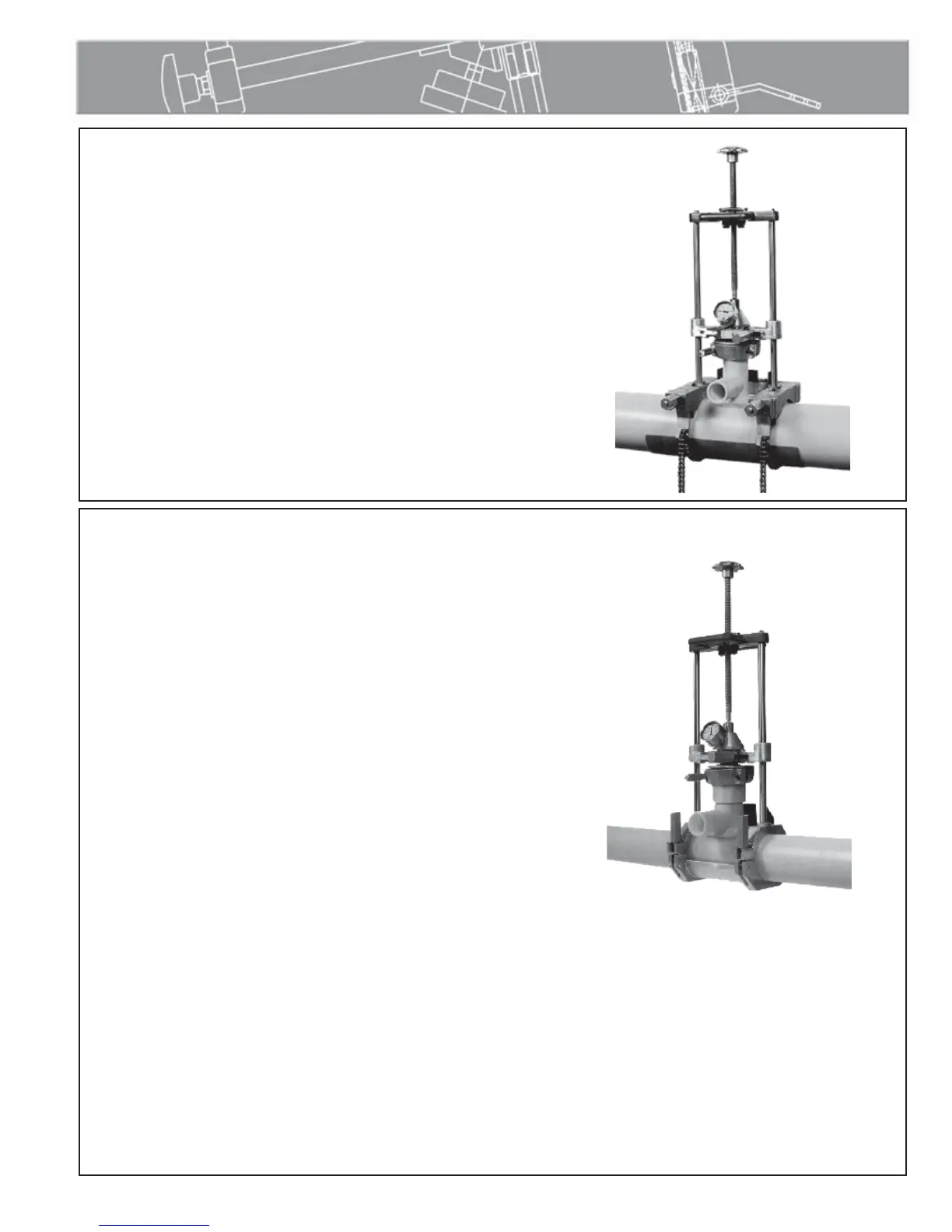

Cold Weather and Coiled Pipe Clamping Procedure

Coiled polyethylene pipe becomes very stiff and hard to handle

when cold. In these conditions, sidewall fusion with the sidewinder

becomes more difficult and requires extra procedures in setting up

the machine.

More clamping force than usual will be needed to straighten

the pipe, caution must be taken not to exceed maximum gauge

pressure.

NOTICE: Exceeding the maximum gauge pressure could damage

the gauge.

Back the clamp knobs out to within 1-1/2 or 2 threads left on the

eye bolt and place the machine on the pipe.

It is more difficult to install the machine on the inside curvature of the

pipe than the outside. For this reason, it may be necessary to

rotate the machine slightly to get the clamp knobs in the proper

position. When the clamp knobs are in the proper position, the

machine can be rotated to the desired position and the clamp

knobs tightened.

Install a fitting in the pivot release master. The fitting will exert

pressure and help straighten the pipe.

Use the drive screw to help straighten the pipe and tighten one

side of the pipe clamp. An 8' crescent clamp may be necessary to

achieve full rounding and straightening. Do not exceed maximum

gauge pressure.

Back the drive screw off as the clamp knobs are tightened, so

maximum gauge pressure is not exceeded.

After clamping one side, continue this process on the opposite

side, making sure the gauge pressure is not exceeded.

TX01444-6-21-10

PH00783-5-3-96

PH00821-5-3-96

Loading...

Loading...