5 - 7

Oil Jaw Pivot Pin

Occasionally, add a drop of light oil to the jaw pivot pin.

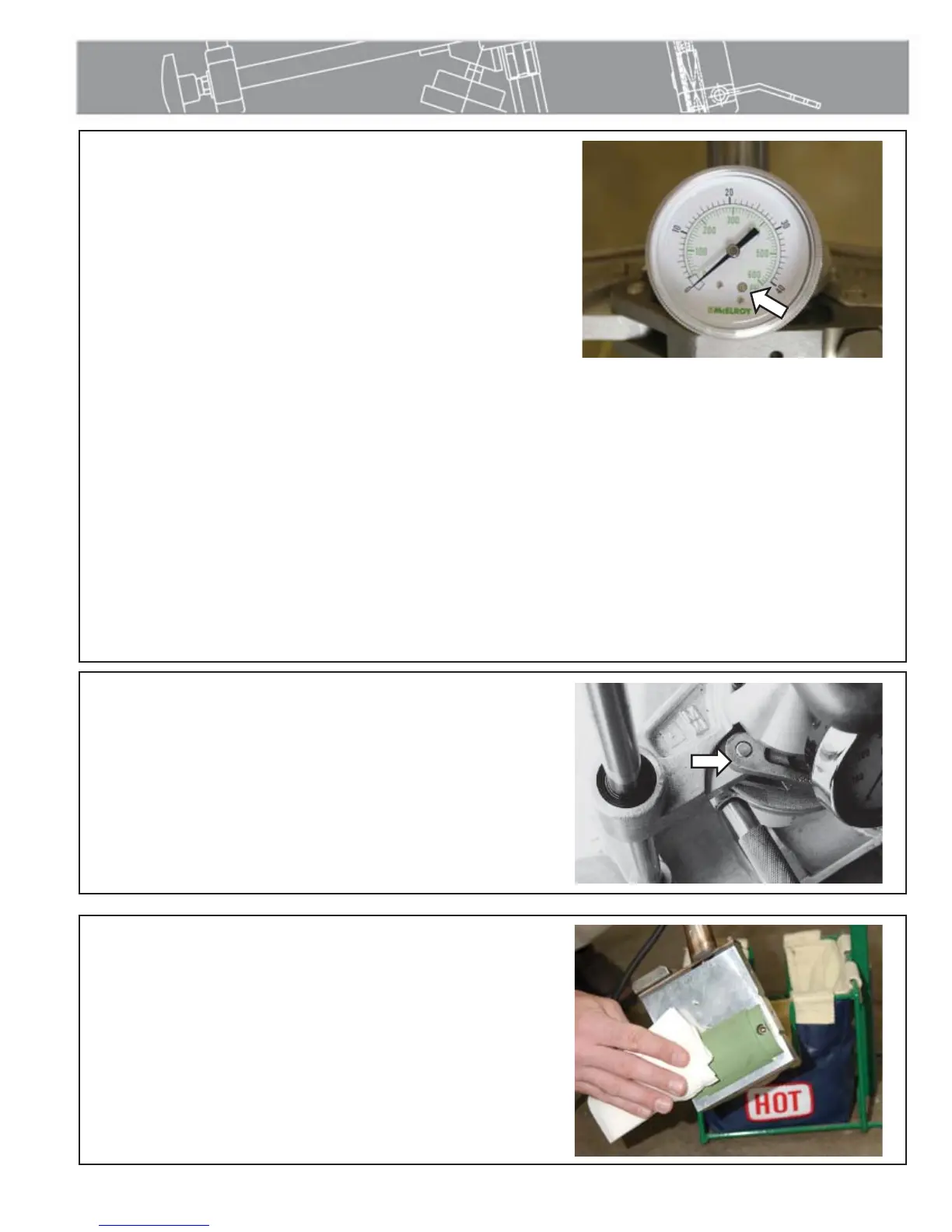

Clean Heater Surfaces

The heater adapters must be kept clean and free of any plastic

build-up or contamination.

Before each fusion is made, the surface of the heater adapters

must be wiped with a clean, non-synthetic cloth.

Maintenance

PH00837-5-6-96

PH02324-4-29-02

TX00946-5-10-96

TX00867-6-15-10

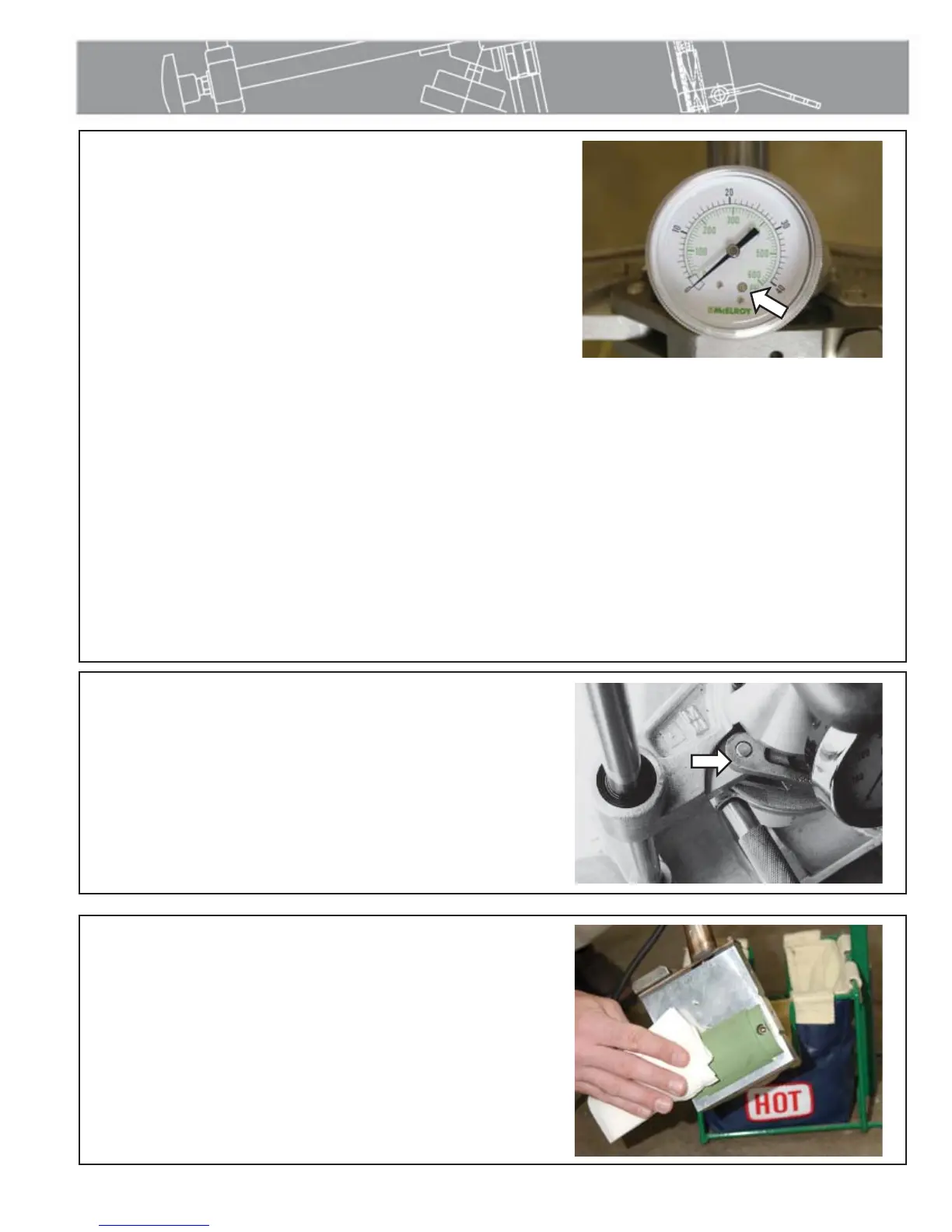

Dry Gauge Calibration

To calibrate the gauge you will need the following:

1. Pressure calibration equipment

2. Adjustable or open end wrench

3. Flat head screwdriver

4. Pliers

Attach gauge to pressure testing apparatus.

Zero the Pointer

With no pressure applied, verify that the pointer is located inside the

zero box area. If the pointer is not within the box, rotate the external adjustment screw pictured until the pointer is in

the center of the box area as shown.

Calibrating Gauge

Using pliers, pull the needle off the gauge, making sure to pull the needle straight out.

Pressurize calibration equipment to a major increment in the operating range of the Sidewinder. Place the needle on

the gauge at the known increment, making sure the needle has snapped into place.

Example: For a Sidewinder with a 300 psi gauge using fittings that require 250 psi, pressurize calibration equipment

to 250 and adjust the needle to 250 psi.

Replace bezel

NOTICE: Applying excess pressure will permanently damage the gauge. Never apply pressure that is greater than the

maximum indication on the pressure gauge. The calibration procedure will not correct a damaged gauge.

TX02498-6-15-10

PH03044-5-27-05

Loading...

Loading...