5 - 6

Maintenance

Checking Installation

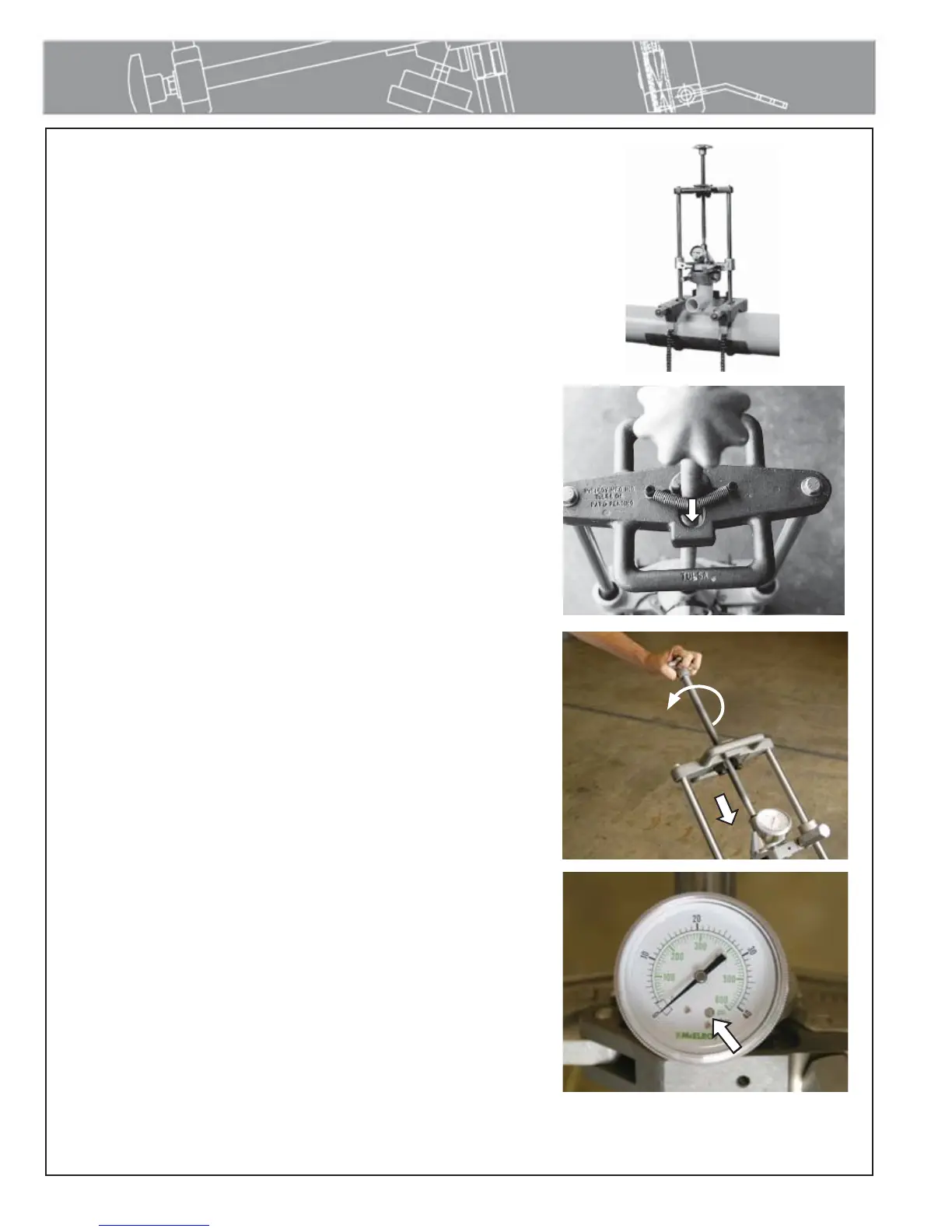

When the gauge is installed, return the Sidewinder to the vertical

position.

Disengage drive screw from threads and lower the saddle fitting

onto the pipe.

Turn the drive screw to move the piston down.

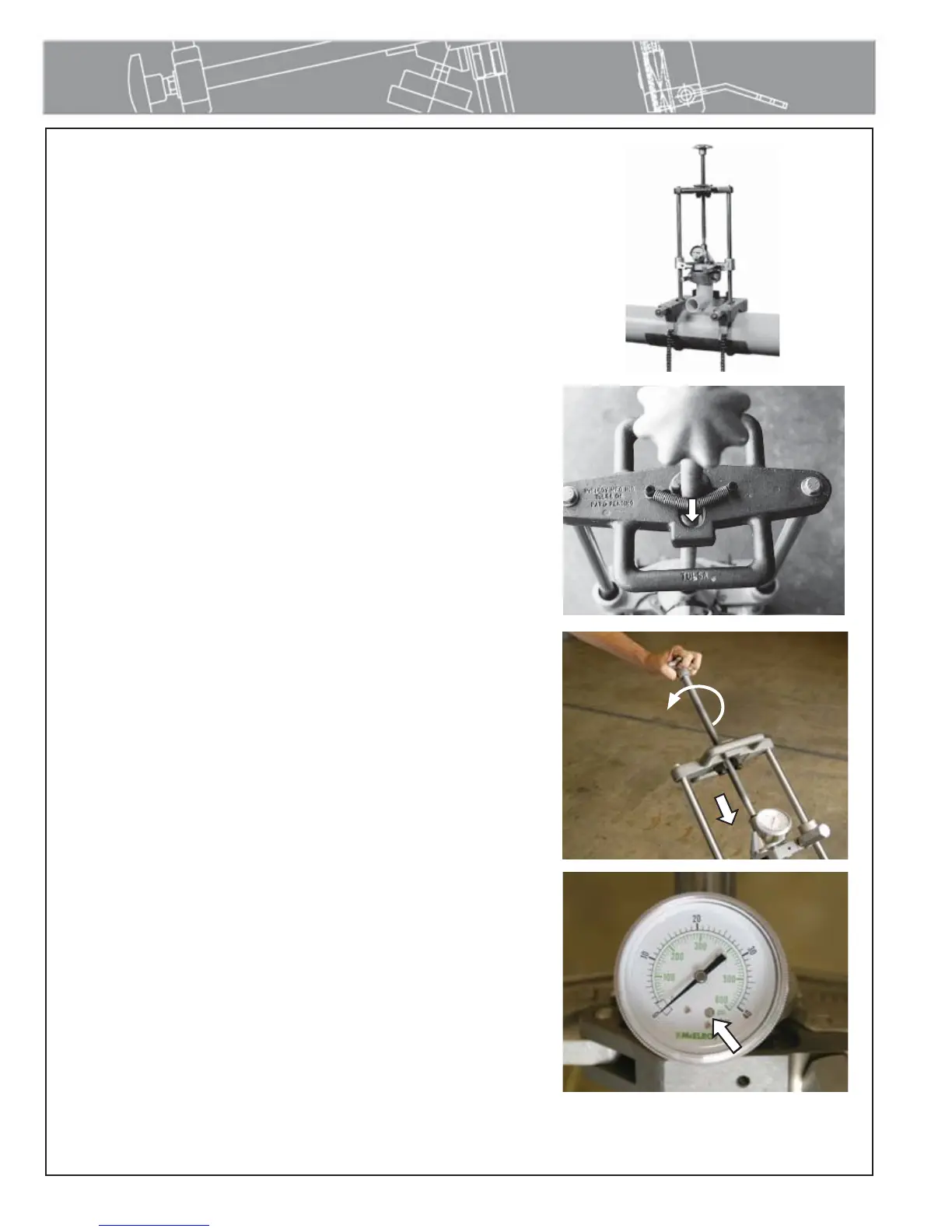

The gauge should indicate pressure within a half turn of the drive

screw knob. If more than a half turn is made with the knob and no

pressure is indicated, the gauge needs to be removed and more

fluid added. Always tilt the Sidewinder back when adding fluid.

Fluid needs to be added until pressure is indicated within the first

half turn of the drive screw knob.

Check the gauge to ensure that it reads zero when no force

is being applied with the drive screw. If the gauge does not

read zero, the load cell may be overfilled or the gauge may be

damaged. If the gauge indicates pressure when the piston is all

the way out, then too much fluid was added and some needs to

be removed.

IMPORTANT: If the gauge pointer is below the zero box area when

no pressure is applied, use the external adjustment screw to move the

pointer to the center of the box area as shown.

NOTICE: Applying excess pressure will permanently damage the

gauge. Never apply pressure that is greater than the maximum

indication on the pressure gauge.

TX01596-3-17-99

PH00783-5-9-96

PH00831-5-3-96

PH03044-5-27-05

PH03045-5-27-05

Loading...

Loading...