For the A-series type of mini chiller, the inter-connecting pipes between the two

compartments are the refrigerant pipes. For the B-series type, there is a water pipe in

between the two compartments.

Therefore, the detached installation of the A-series mini chillers is very similar to the

installation of a split type air-conditioning unit.

Note:

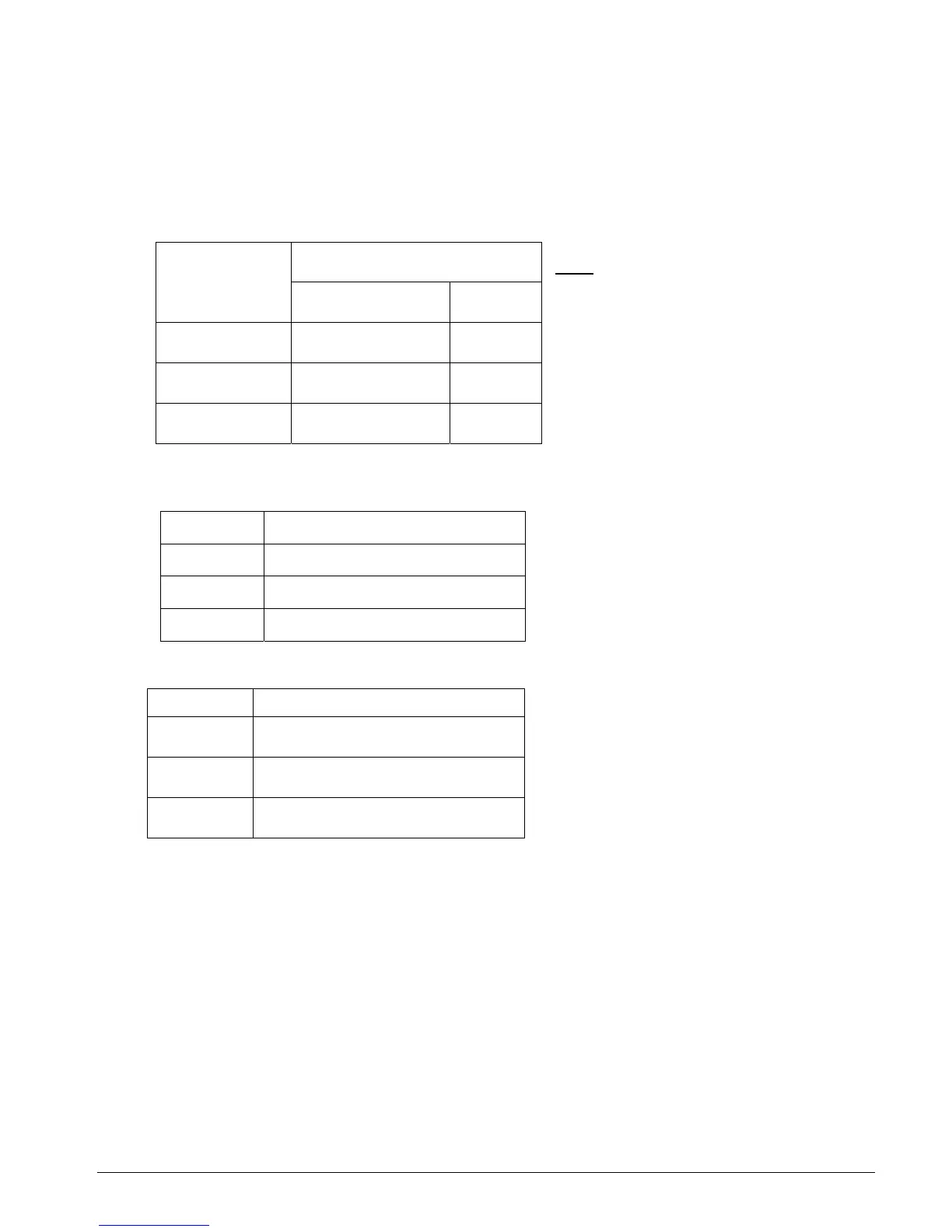

Gas line to be insulated with

tube insulation. Use the

correct size for each pipe, thickness

¼

”

Refrig. Pipe size

Liquid Gas

AC 040A

3/8” ¾”

AC 050A

3/8” ¾”

AC 058A

½” ¾”

Take care of the following items [for detached A-series installations]:

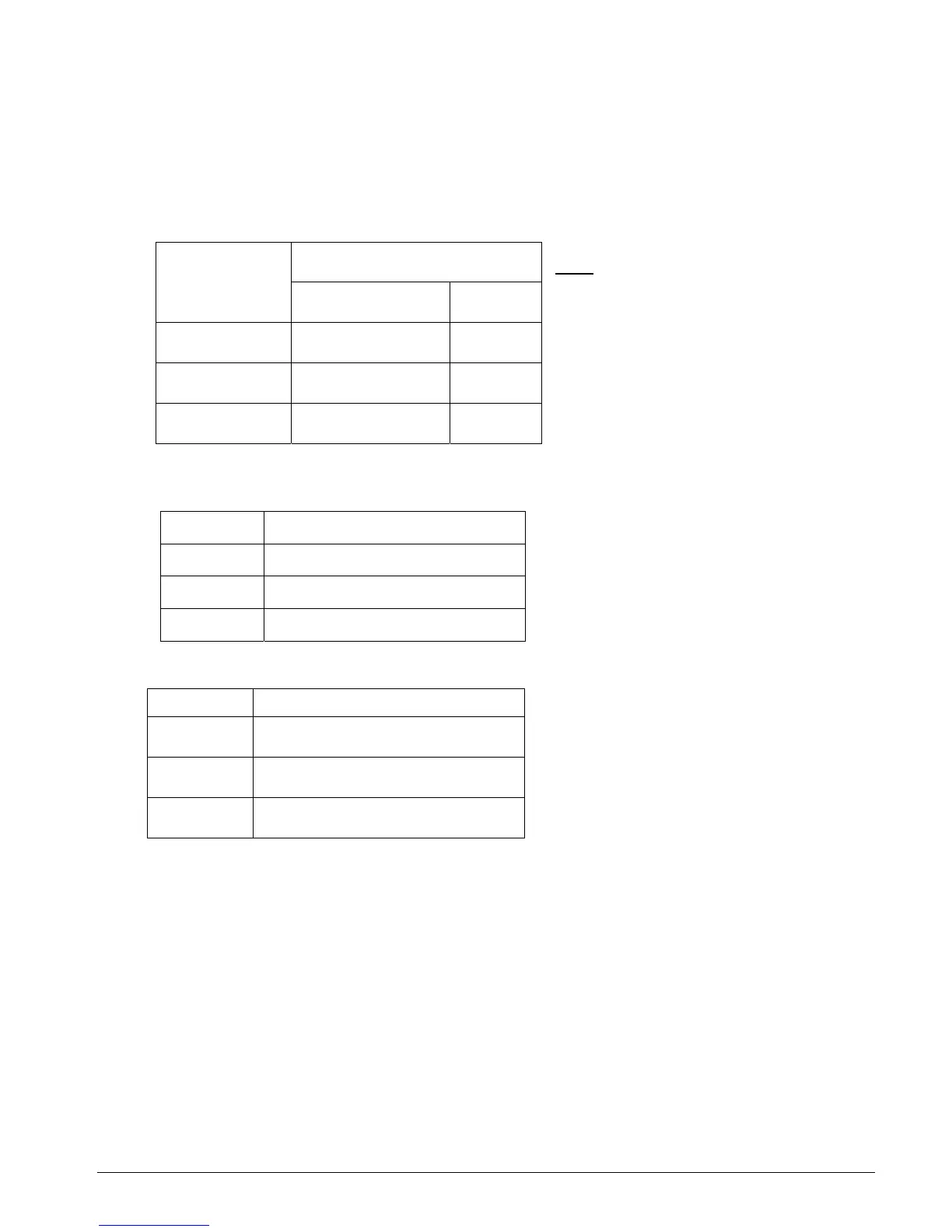

Maximum pipe length,m

AC 040C

20

AC 050C

20

AC 058C

20

a) Do not allow excessive refrigerant pipe

length between the two compartments.

Always choose the shortest path.

Long piping will cause high pressure

drops and reduces the capacity of the

system. Use the following

recommendations:

Maximum elevation, m

AC 040A

10

AC 050A

10

AC 058A

10

b) It is possible to have the hydraulic kit

higher or lower than the refrigerant

compartment. Do not allow excessive

elevation between these two

compartments. Use the following

recommendations:

If the elevation exceeds the above recommendations, care must be taken to ensure sufficient oil

return to the compressor. Use oil traps (one every 30ft height interval) or oil separators, if

necessary.

c) The longer pipe lengths will require more refrigerant charge for optimum

performance.

Recommendation: Additional 50g (R-22) for every 1 meter of connecting pipe length.

Similarly, additional refrigerant oil charge may be required.

Section 1 Page 7

Loading...

Loading...