Product Manual PM WSC/WDC 11

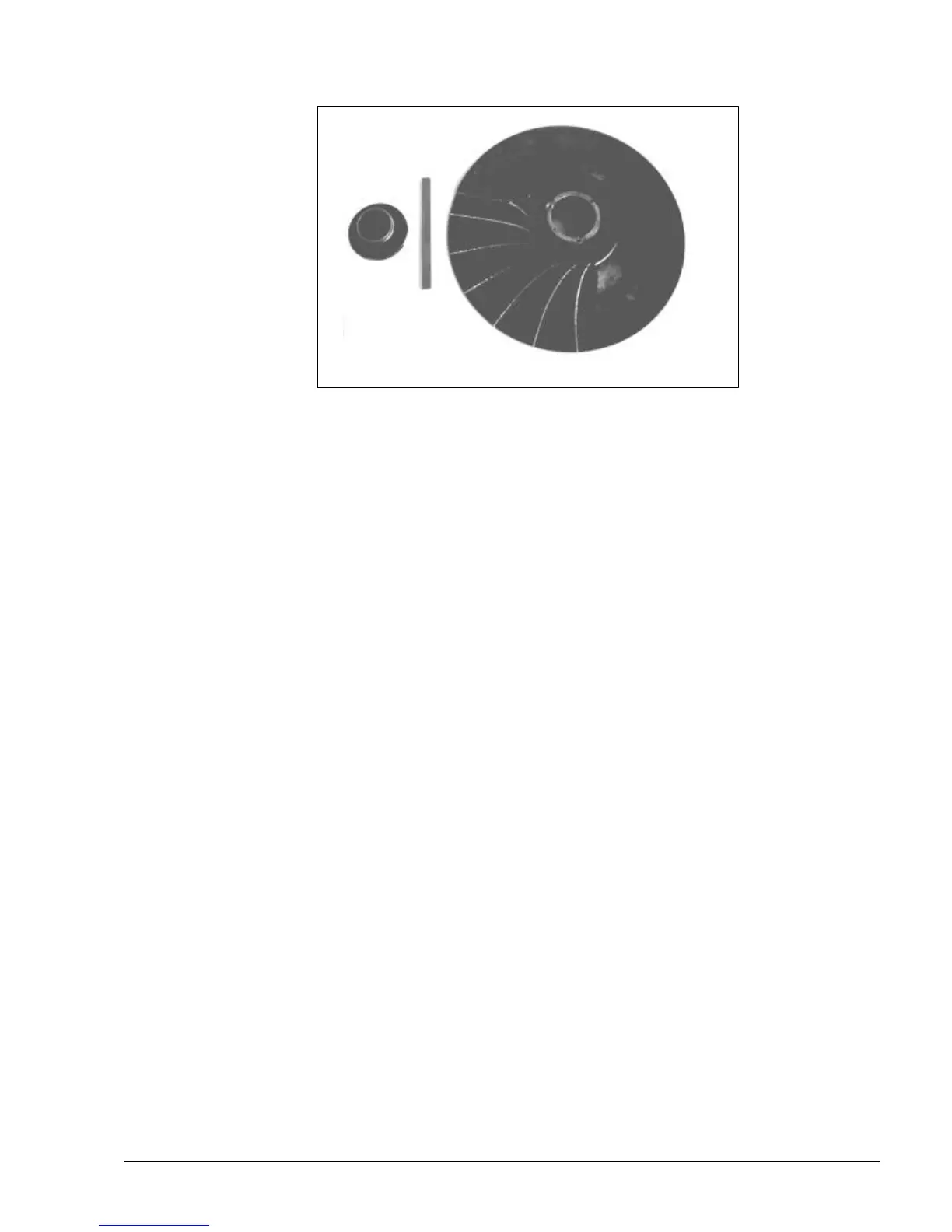

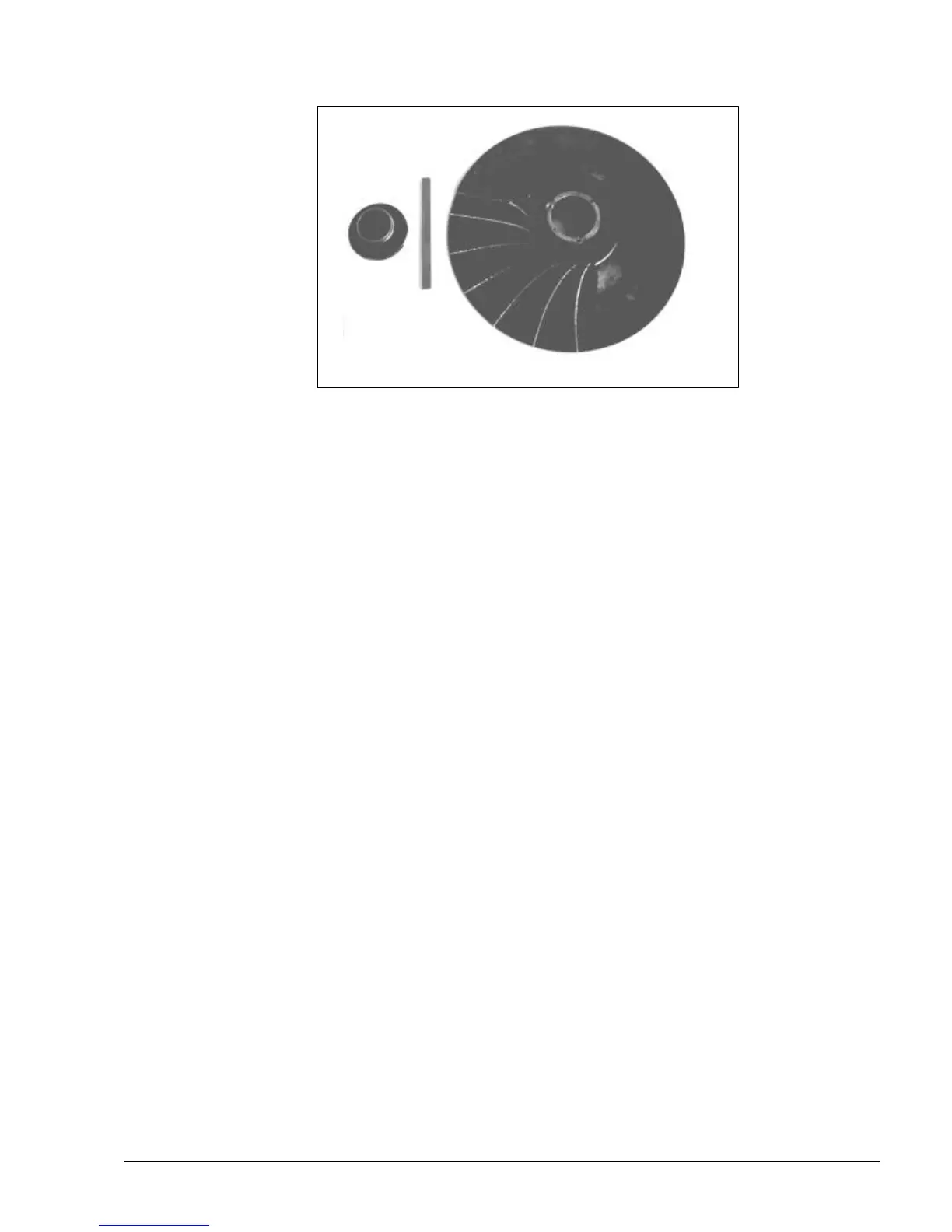

HFC 134a Impeller Compared to HCFC 123 Impeller

Left: Impeller from a McQuay single stage 300 ton (1050 kW) compressor; diameter = 6.3 in. (16 cm), weight =

3.0 lb (1.4 kg)

Right: One of three impellers from a 300 ton HCFC-123 compressor; diameter = 26 in. (66 cm), weight = 27 lb.

12.2 kg)

Compact Design

Small Footprint Cuts Installation Costs

At comparable cooling capacities, HFC-134a requires less than 3.2 cfm (1.5 l/sec) per ton of refrigeration to be

circulated by the compressor. HCFC-123 requires over 18.0 cfm (8.5 l/sec) per ton. The substantial increase in

refrigerant volume requires significantly larger suction piping and compressor components in negative pressure

designs to maintain reasonable gas velocity, noise levels and refrigerant pressure losses. Conversely, the small

physical size of McQuay centrifugal chillers will:

• Permit design of smaller equipment rooms.

• Cost less to rig and install.

• And, in smaller capacities, allow transit through standard equipment room doors, permitting building

construction to proceed on schedule before receipt of the chiller equipment.

• Lower joint surface area for lower likelihood of leaks.

Bolted Design Eases Retrofit Installation

The major components; evaporator, condenser, and compressor, are bolted together and can be taken apart in

the field to facilitate difficult rigging work. The chillers are shipped assembled from the factory and

disassembled and reassembled on site under supervision of authorized McQuay service personnel. Individual

component weights are shown in the Physical Data section.

Note: The compressor must be removed if the evaporator is to be rigged in a vertical position.

Loading...

Loading...