22 Product Manual PM WSC/WDC

Building Management Systems

All MicroTech unit controllers and system controllers are capable of Open Protocol communications providing

seamless integration and comprehensive monitoring, control and two-way data exchange with virtually all

Building Management Systems.

Here are just a few of the 220 points on a WDC chiller that are available remotely through one simple, low cost

twisted-pair interface.

Operating Parameters Safety/Cycling Conditions

Entering/leaving water temperatures High and low refrigerant pressures

Refrigerant temperatures and pressures Oil pressure differential

Motor amps as a percent of FLA Motor condition from embedded sensors

Hours of operation and number of starts System water pump failures

Chilled water and demand limit setpoints High discharge temperatures

Cause and conditions for last eight shutdowns Starter fault

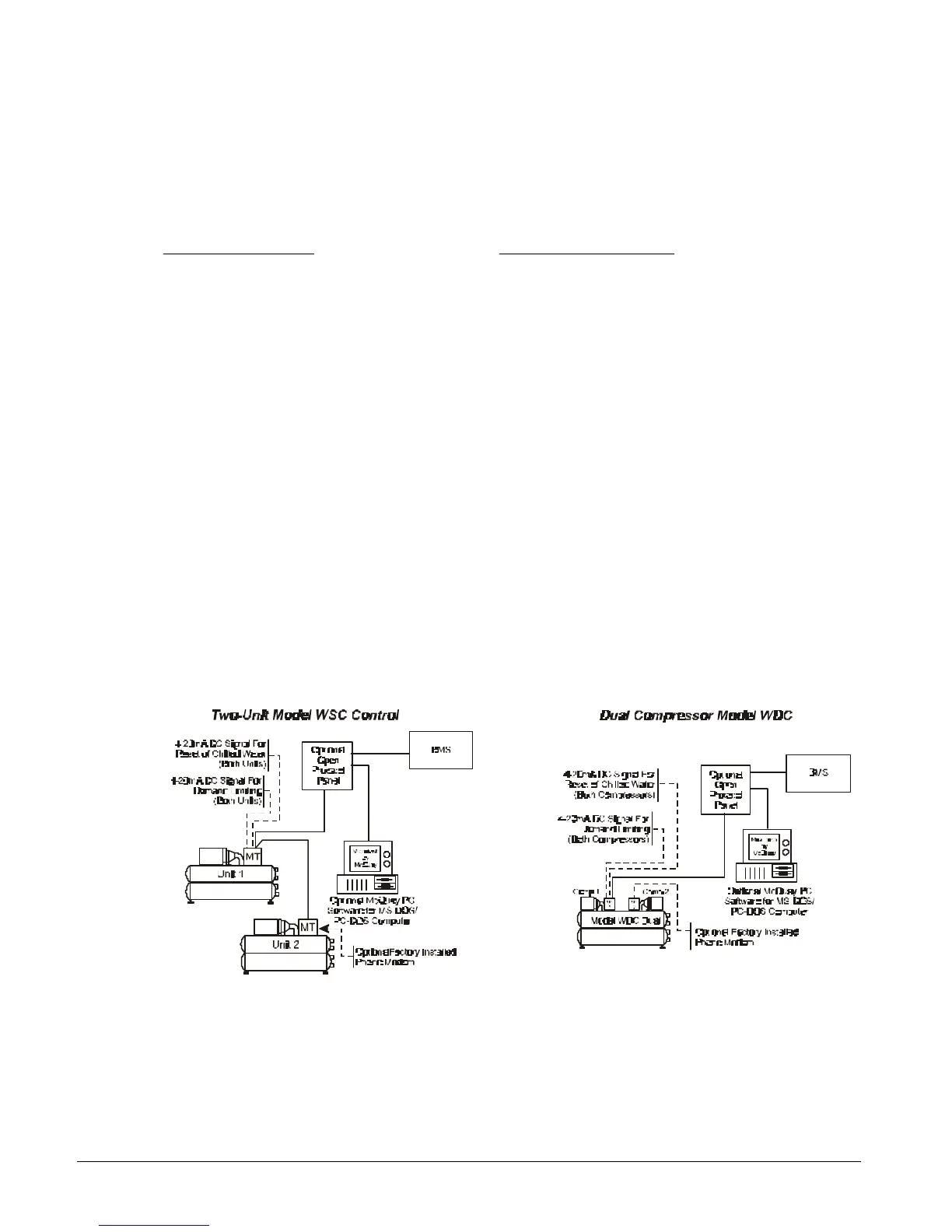

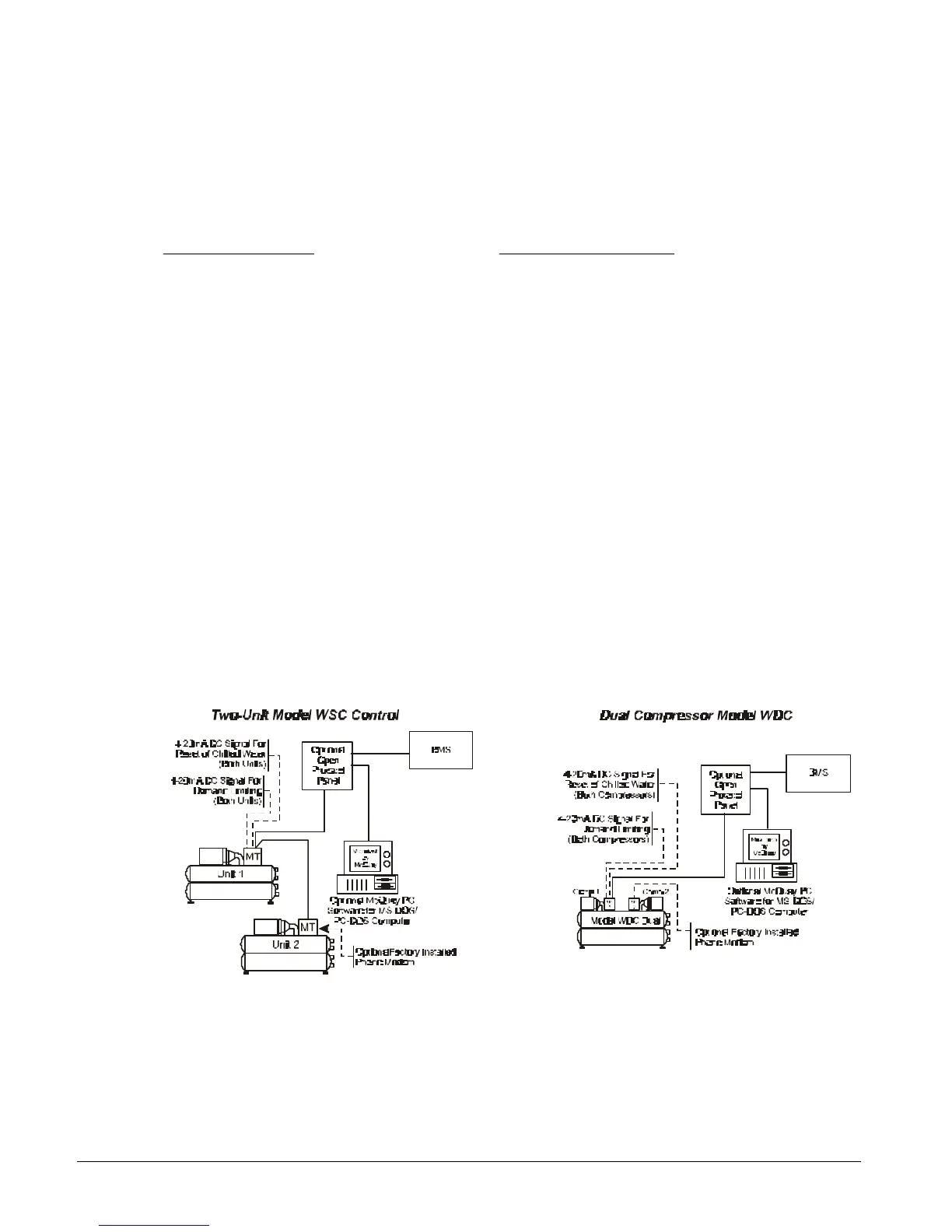

Multiple Machine Control

Two WSC Units or One WDC Dual Compressor Unit

The lead-lag/load balance function is a standard feature of each MicroTech panel. It provides sequencing

control, load balancing and single point control for BMS interface for reset or demand limiting of either

compressor.

Lead-lag can be selected as manual or automatic. In automatic, the compressor with the least starts will start

first and the compressor with the most hours will stop first.

Load balance equalizes the load between the two compressors providing optimum efficiency and preventing

short cycling of the lag compressor.

Loading...

Loading...