Product Manual PM WSC/WDC 47

Electrical Data

Centrifugal compressor motors have been redesigned to increase efficiencies well into the 90% range. This

design change is particularly important since it represents a motor characteristic that directly impacts the

system’s watt-hour meter. In addition, the motor efficiency, unlike power factor, is a design characteristic that

cannot be improved on the job.

Motor and Voltage Code

The typical unit model number below displays the three digits used to identify the motor and voltage codes:

WSC 126K BS 72 R

The motor described by motor and voltage code letters will determine the maximum kW, locked rotor amperes,

power factor and voltage found in the Motor Data Tables.

Wiring and Conduit

Wire sizes should comply with local and state electrical codes. Where total amperes require larger conductors

than a single conduit would permit (limited by dimensions of motor terminal box), two or more conduits may be

used. Where multiple conduits are used, all three phases must be balanced in each conduit. Failure to balance

each conduit will result in excessive heating of the conductors and unbalanced voltage.

An interposing relay may be required on remote mounted starter applications when the length of the conductors

run between the chiller and starter is excessive.

Note: On WDC dual compressor units, dual power leads are standard, requiring separate power leads properly

sized and protected to each compressor starter. Separate disconnects must be used.

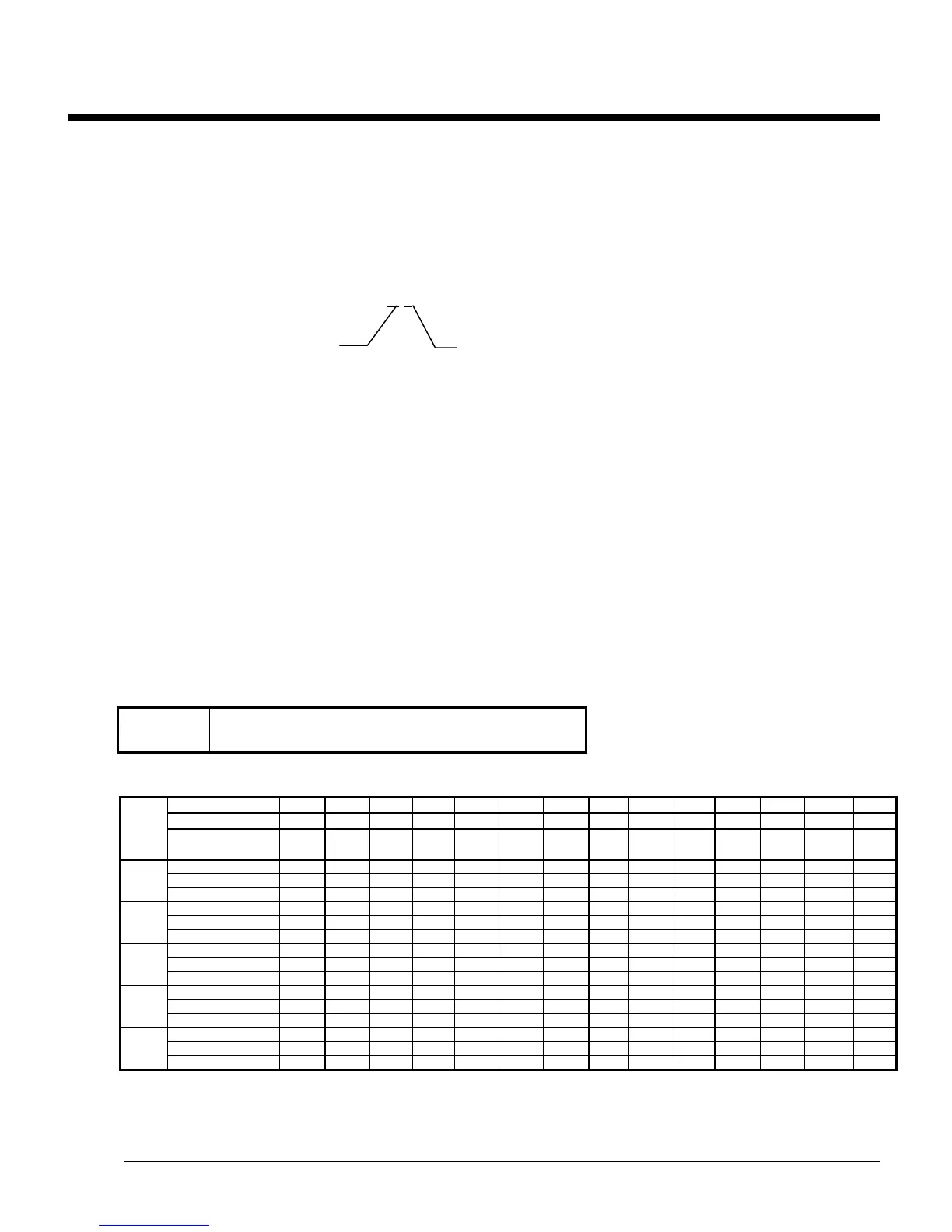

Motor Data

10⇒ Motor nominal horsepower ÷ 10

A⇒ Compressor that motor is used on; A = 050, B = 063 to 087, C = 100 to

126

60 Hertz

Nameplate Volts 200 208 220 230 240 380 440 460 480 575 2400 3300 4160 6600

Voltage Code N B P V W U A R S D M C L 2Motor

Code

Min/Max Volts

180/

220

187/

229

198/

242

208/

253

216/

264

342/

418

396/

484

414/

506

432/

528

518/

633

2160/

2640

2970/

3630

3744/

4575

5940/

7260

(Continued next page)

Motor Code

Voltage Code

Loading...

Loading...