12 Product Manual PM WSC/WDC

Heat Exchangers

High Performance Shell-and-Tube Flooded Evaporators

McQuay packaged centrifugal chillers are equipped with new high performance heat exchangers. The unique

design greatly increases heat transfer and reduces unit footprint and refrigerant charge compared to previous

designs. In many cases vessel length has been reduced by 40 percent. Chillers are designed, constructed and

tested in accordance with ASME Section VIII, ASHRAE Standard 15 requirements and TEMA recommendations.

The replaceable water tubes are integral internally and externally enhanced copper and are mechanically bonded

to steel tube sheets. Standard tubes are 0.025 inch wall copper in the evaporator and 0.028 inch wall copper in

the condenser. Optional tubes include 0.028 inch evaporator and 0.035 inch on either vessels and 90/10 cupro-

nickel, 304 stainless steel or titanium material. Clad tube sheets and epoxy coated heads are included when

other than copper tubes are specified.

Vessels are available for 1, 2 or 3 pass water flow. A 3/4" thick vinyl/nitrate polymer evaporator insulation is

standard. All seams are glued to form an effective vapor barrier. The entire chiller barrel including non-

connection heads and tube sheets are factory insulated. Detailed information on the insulation can be found

under “Physical Data” in this catalog.

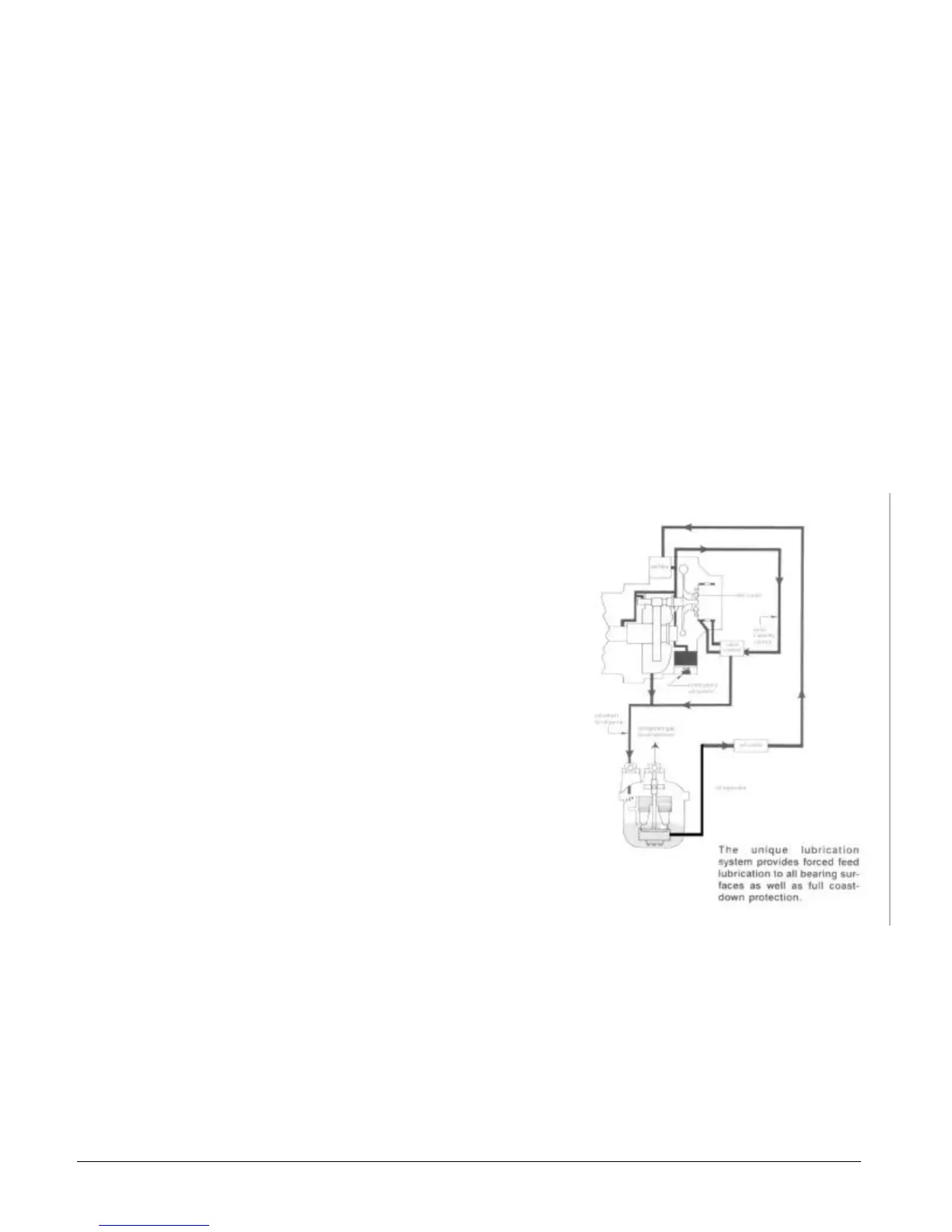

Lubrication System

A separately driven electric oil pump assembly supplies

lubrication at controlled temperature and pressure to all

bearing surfaces and is the source of hydraulic pressure

for the capacity control system.

The control system will not allow the compressor to start

until oil pressure at the proper temperature is established,

and also allows the oil pump to operate after compressor

shutdown to assure lubrication during coast down.

Lubricant from the pump is supplied to the compressor

through an external brazed-plate heat exchanger and

internal single or dual 5 micron oil filter. All bearing

surfaces are pressure lubricated. Drive gears are operated

in a controlled lubricated mist atmosphere that efficiently

cools and lubricates them.

Lubricant is made available under pressure from the

compressor oil filter to the unit capacity control system and

is used to position the inlet guide vanes in response to

changes in leaving chiller water temperature.

Should a power failure occur an emergency oil reservoir

guarantees adequate lubrication flow under pressure and

prevents damage that could occur during the spin down

period with the oil pump stopped.

Since the McQuay chillers are positive pressure there is no need to change lubricant or filter on a regular basis.

An annual oil check is recommended to evaluate the lubricant condition.

Loading...

Loading...