8 Product Manual PM WSC/WDC

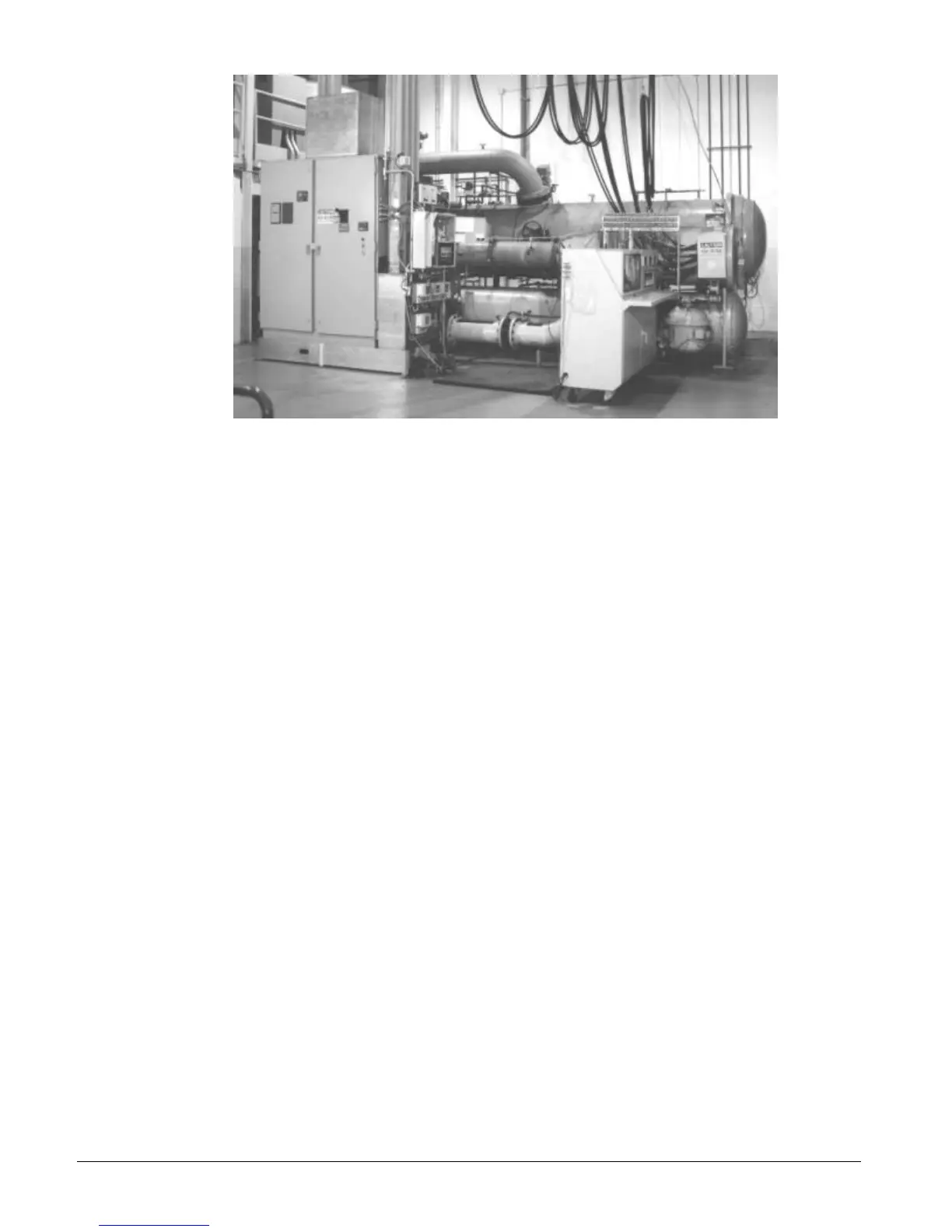

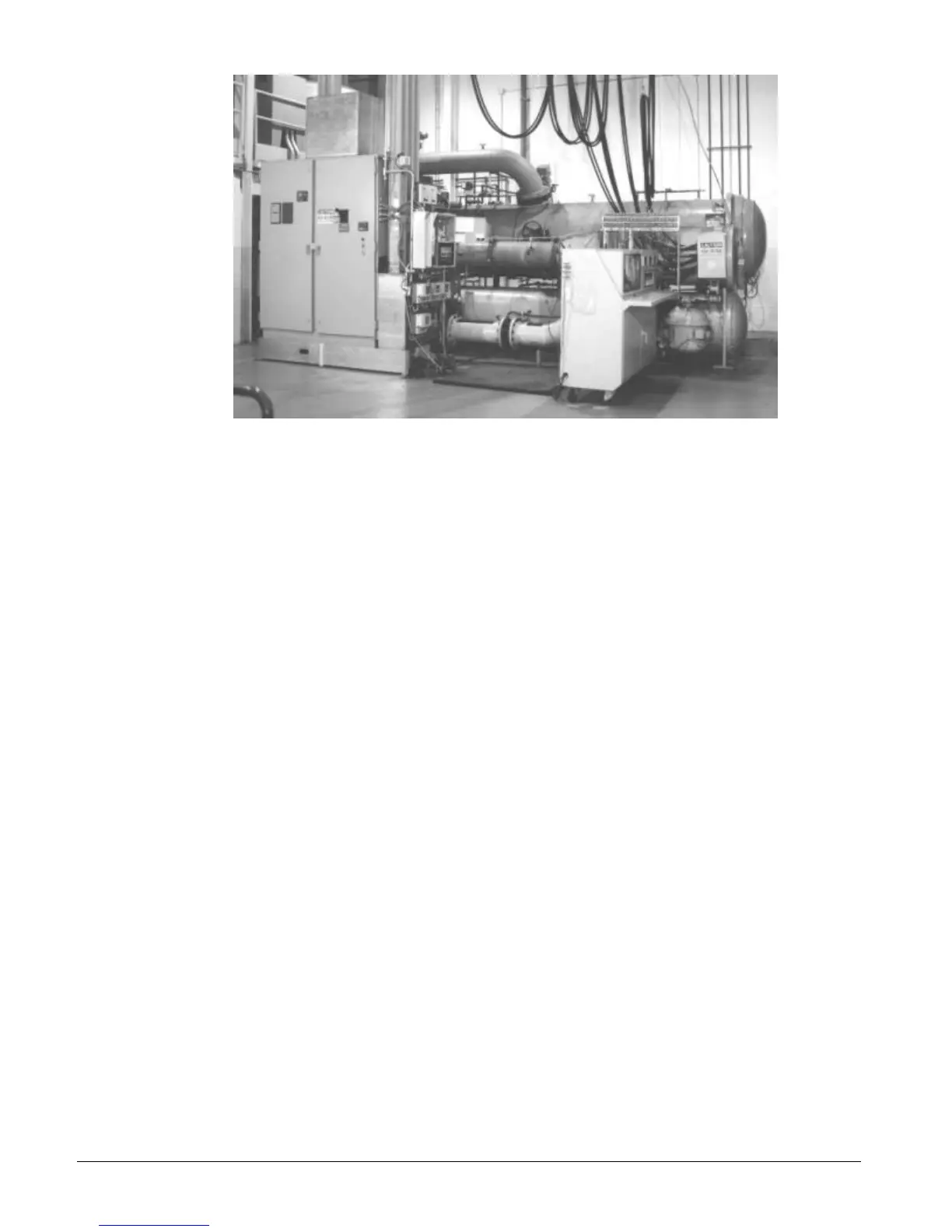

McQuay’s new million dollar compressor test stand with state-of-the-art data

acquisition provides comprehensive information on new compressor designs.

Single Stage Simplicity = Savings

Compressor efficiency is NOT a function of multiple impellers. Maintenance of optimum efficiency at peak and,

more importantly, at part load is a function of the total compressor and chiller design. Included are:

• Motor efficiency

• Refrigerant type

• Condenser and evaporator surfaces

• Compressor mechanical friction

• Impeller and vane design

• Refrigerant flow passages

Of these, the least considered performance factor on actual versus theoretical performance is the refrigerant flow

passages between the discharge of one impeller and the inlet to the next impeller on multi-stage machine design.

The energy loss in a single passage will be greater or equal to the loss in the suction passage between the

evaporator outlet and the first stage impeller inlet, depending upon the compactness of the total compressor

design. Single stage impeller design eliminates that additional loss, and provides an opportunity for maximum

system efficiency.

The primary advantage to multi-stage centrifugal operation, in the pressure and volume ranges characteristic of

typical air conditioning systems, is the expansion of impeller head coefficients at reduced volumetric flows or

cooling loads. The McQuay backward inclined SINGLE STAGE IMPELLER, combined with the patented

movable diffuser at the impeller discharge, provides a stable operating range superior to multi-stage systems.

Thus, selection of McQuay chillers permits operation from 100% to 10% capacity (to 5% on WDC dual

compressor chillers) without surging and at maximum efficiency, i.e. no hot gas bypass.

Optimum compressor efficiency is designed into each McQuay impeller. Each is cast, fully shrouded, by the

lost wax process that provides exact duplication despite a complex configuration of 16 backward inclined,

strategically spaced blades. The McQuay designed impeller not only minimizes pressure loss at the inlet and

maximizes compression efficiency, but also breaks up pure tone sound to operate at competitively low sound

power levels. A simple short diffuser and a volute design passing compressed gas directly into the condenser

maintain the compressor efficiency.

Loading...

Loading...