OM Centrif Micro ΙΙ-5 9

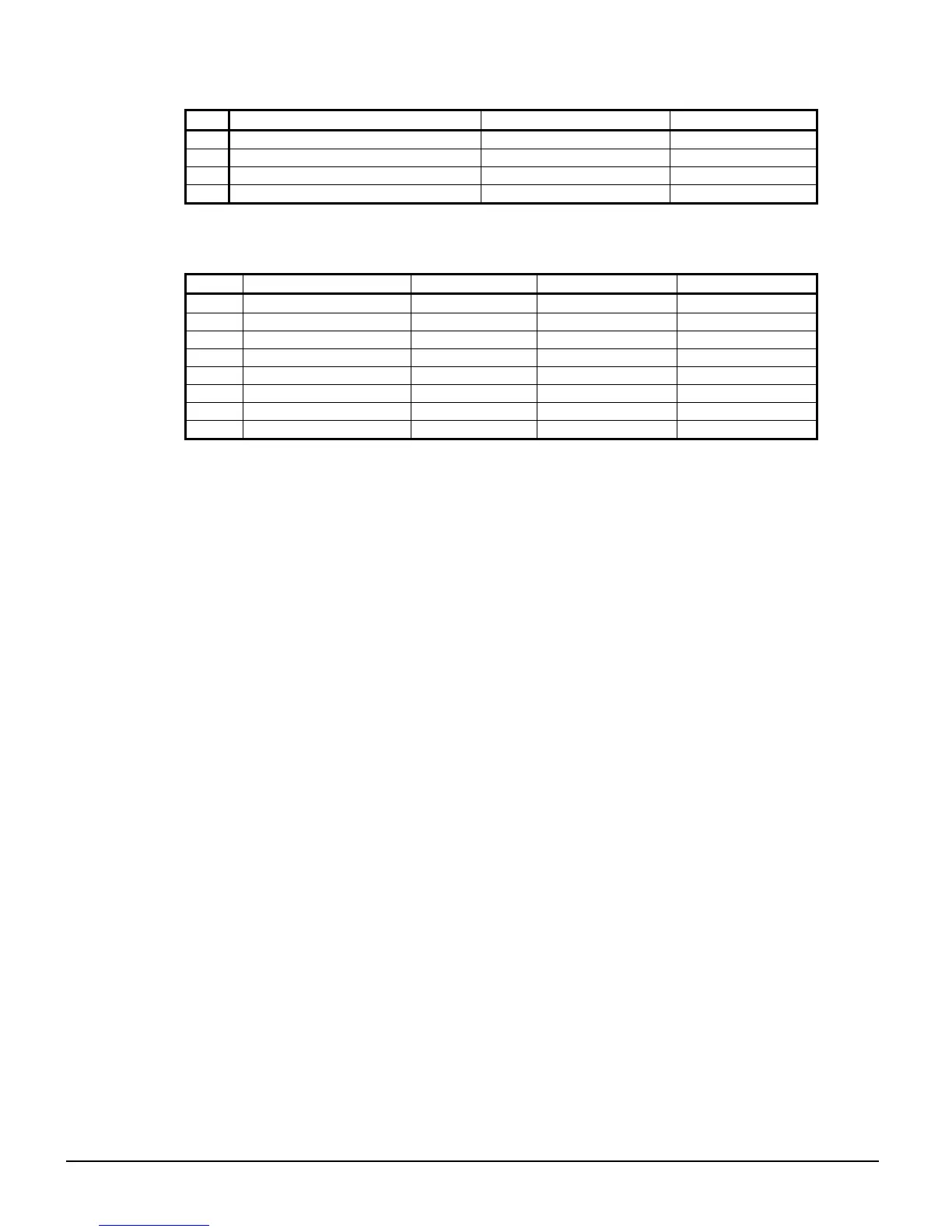

Table 7, Compressor Controller, Analog Outputs

# Description Output Signal Range

Y1

Compressor VFD Speed 0 to 10 VDC 0 to 100%

Y2

Open

Y3

Oil Cooler 0 to 10 VDC 0 to 100%

Y4

Hot Gas Bypass 0 to 10 VDC 0 to 100%

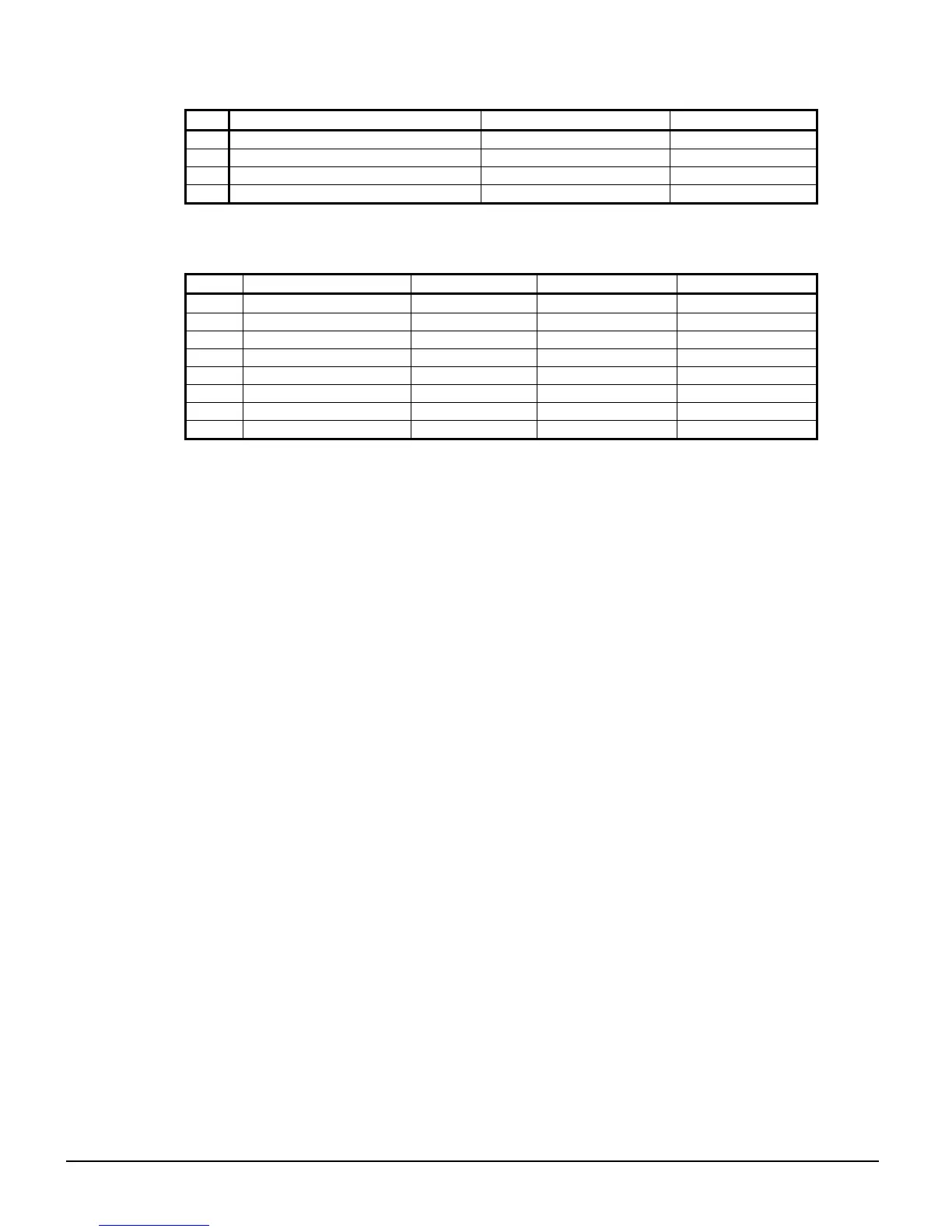

Table 8, Compressor Controller, Digital Outputs

# Description Load Output OFF Output ON

NO1

Motor Control Relay Starter Compressor OFF Compressor ON

NO2

Hot Gas Bypass Solenoid No Bypass Bypass

NO3

Liquid Injection Solenoid No Injection Injection

NO4

Oil Pump Pump Contactor Pump OFF Pump ON

NO5

Oil Sump Heater Heater Heater OFF Heater ON

NO6

Oil Cooler Solenoid Cooling OFF Cooling ON

NO7

Vane Pulse Solenoid Hold Move Vanes

NO/C8

Load/Unload Solenoid Unload Load

Guardister

Board

The Guardister board monitors the motor winding temperature through embedded Guardistor

temperature sensors in the motor. If the motor temperature rises to an unsafe level, the board will

signal the compressor controller and the compressor will shut down.

Signal Converter Board

On medium voltage starters, the AC current signal generated by the starter is converted by the

separate signal board into a 0-5 VDC signal that is directly proportional to the compressor motor

amp draw. The amp draw signal is sent to the compressor controller.

On low voltage starters, the D3 starter feature eliminates the need for this board.

Transducer Converter Board

The transducer converter board converts the pressure transducer signal to the correct voltage signal

and relates it to the compressor controller.

PLAN Isolator

Provides voltage isolation on the pLAN (RS485) when interconnecting chillers on the pLAN.

Loading...

Loading...