EN

22

STERILIZATION METHOD - Torque wrench

The sterilization process in steam autoclave

must be performed setting the parameters

indicated below, which are validated by

Mectron and reach the sterilization safety

levels (SAL 10

-6

):

- 3 times Pre-vacuum

(minimum pressure 60 mBar).

- Sterilization temperature 132°C

(interval 0°C ÷ +3°C).

- Sterilization time 4 minutes.

- Minimum drying time 10 minutes.

All the sterilization phases must be performed

by the operator in compliance to the norms

UNI EN ISO 17665-1:2007, UNI EN ISO

556-1:2002 e ANSI/AAMI ST 46:2002.

WARNING: Checking infections - Parts

that can be sterilized - Diligently remove

all residues of organic dirt before the

sterilization.

CAUTION: Perform the sterilization

using a water steam autoclave only. Do not

use any other sterilization procedure (dry

heat, irradiation, ethylene oxide, gas, low

temperature plasma, etc.).

CAUTION: do not exceed the allowed

load of the steam sterilizer.

PREPARATION

- Perform the CLEAN function

(see Chapter 02)

- Remove the tube from the pump

(see Chapter 03)

- Disconnect the tube from the connector of

the handpiece (see Chapter 03). If the bone

grafting kit is used, disconnect the tube-to-

tube connector from both tubes

MATERIALS NECESSARY

- Enzymatic detergent with pH 6-9

- Water

- Container for the immersion in the

enzymatic solution

- Distilled water

- Single-use sterilization packets

- Steam sterilization

CAUTION: Do not use hydrogen

peroxide. If you intend to disinfect the

tubes, do not use hydrogen peroxide, but

only disinfectants with neutral pH (pH7);

always rinse with sterile water to preserve

the disinfection.

CAUTION: Once used, correctly dispose

of the enzymatic detergent solution, do

not recycle.

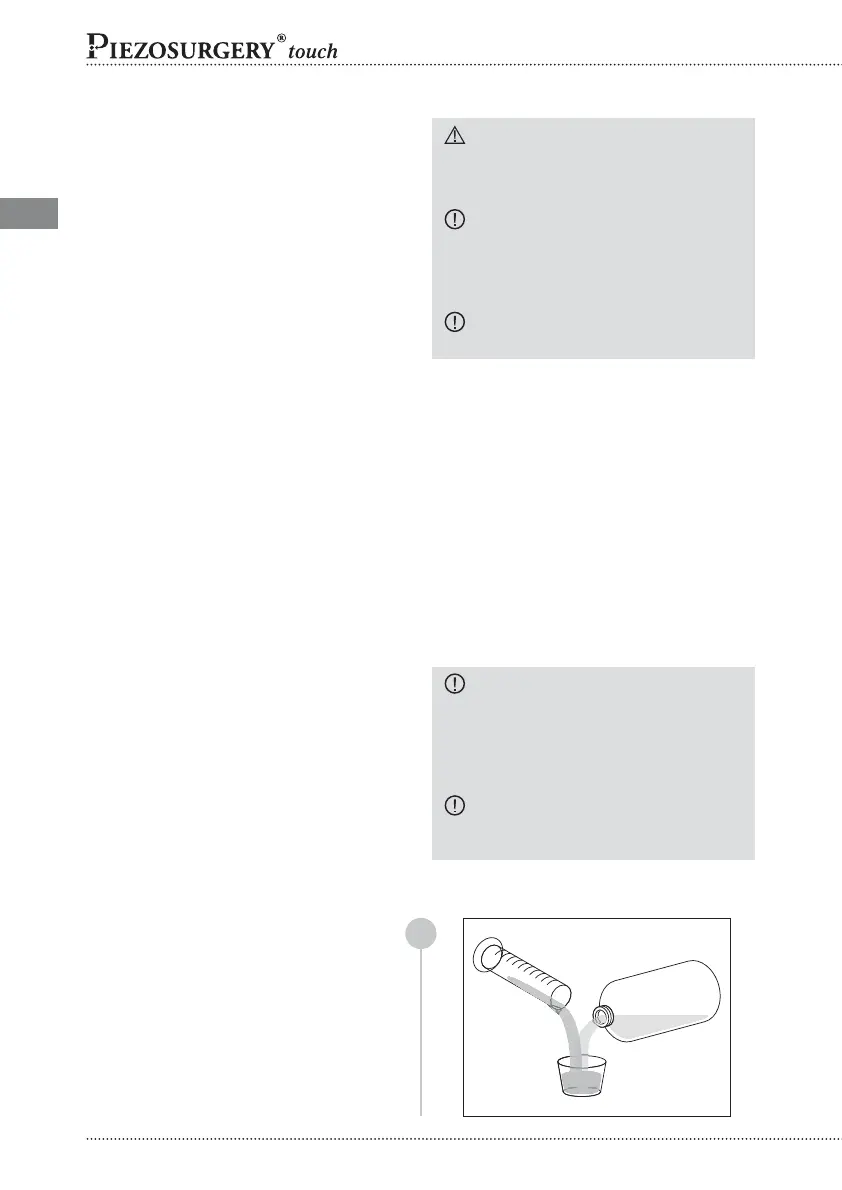

CLEANING AND DISINFECTION METHOD - Peristaltic pump tubes

05.6

Û

CLEANING AND STERILIZATION

OF THE PERISTALTIC PUMP TUBES

1

Prepare an enzymatic detergent solution

with pH 6-9, as per the instructions of the

manufacturer;

Loading...

Loading...