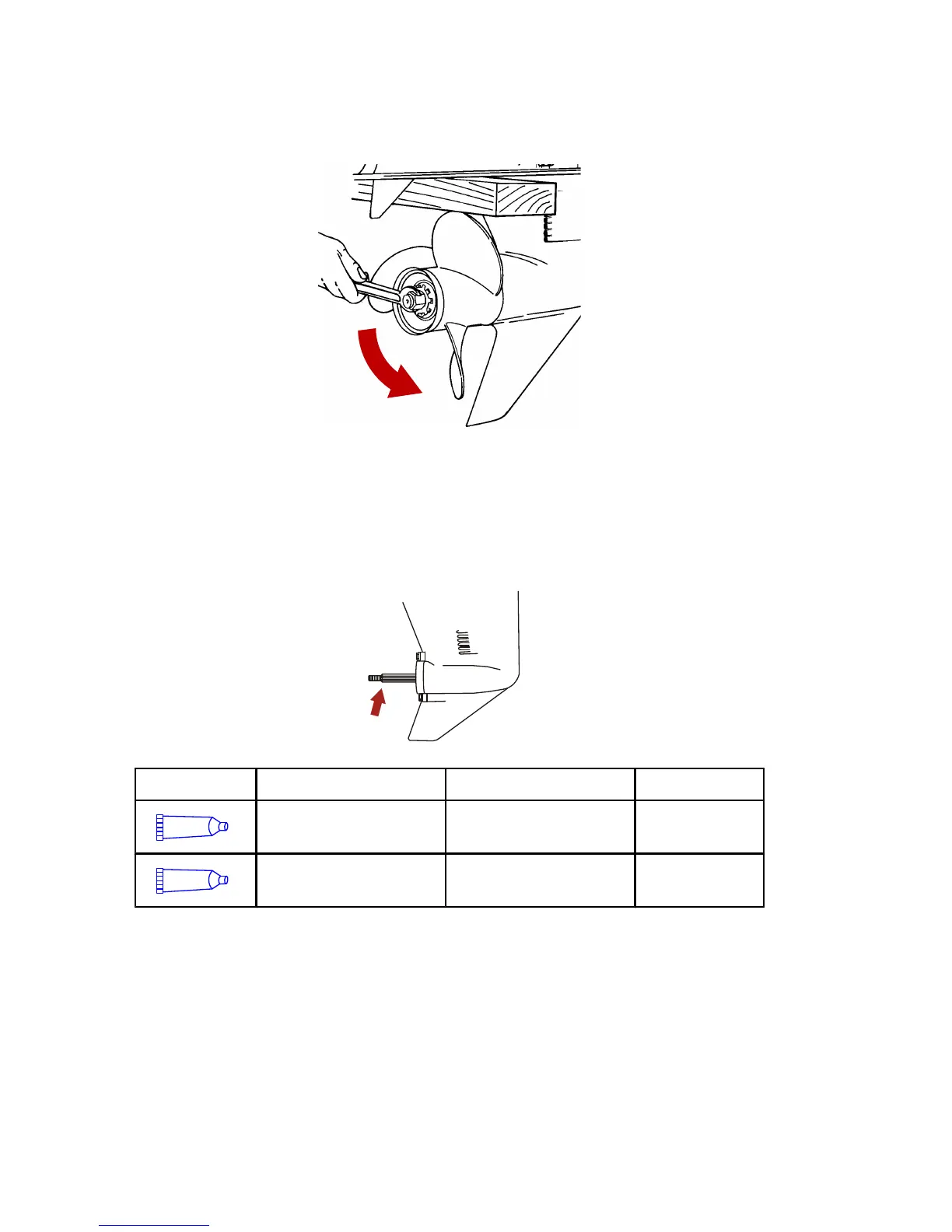

5. Pull propeller straight off shaft. If propeller is seized to the shaft

and cannot be removed, have the propeller removed by an

authorized dealer.

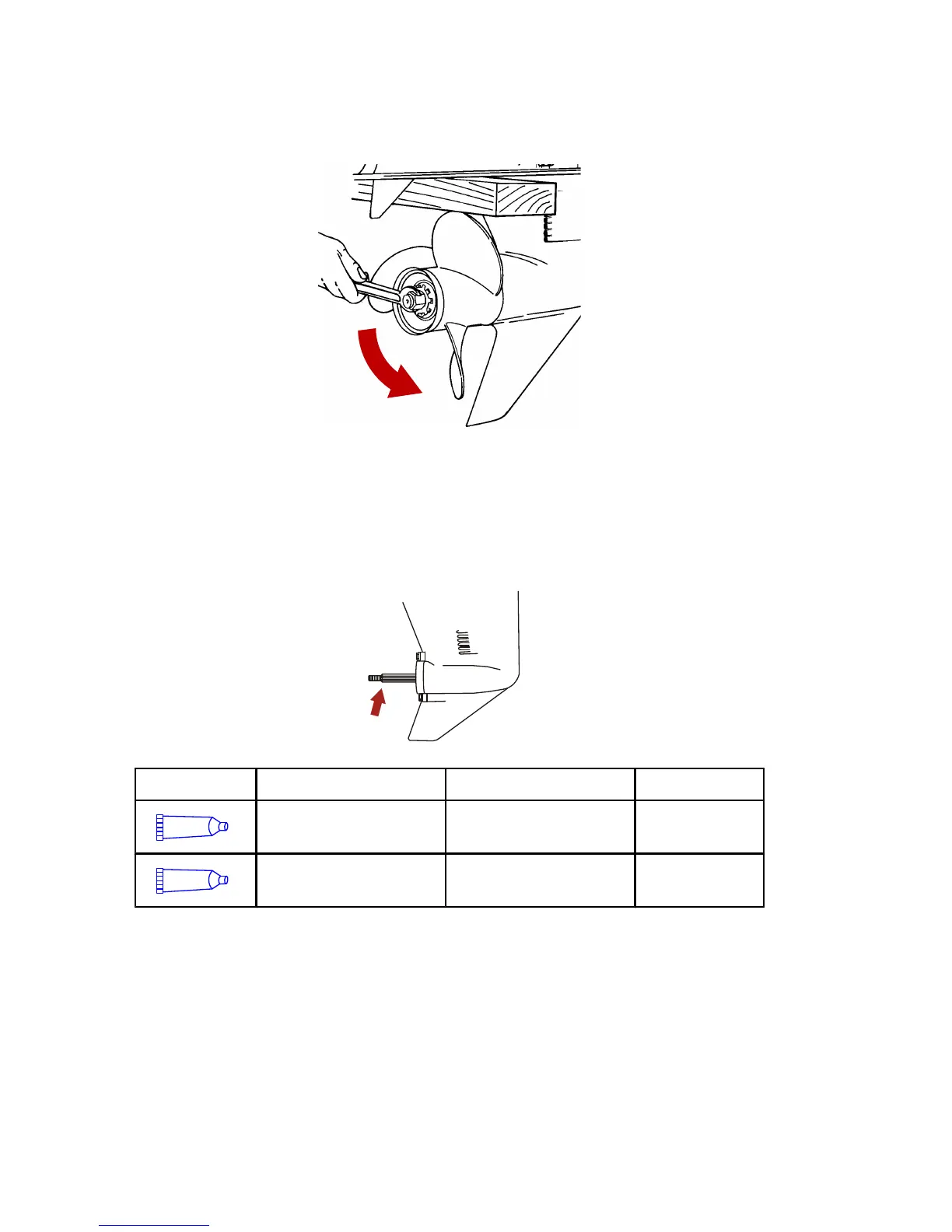

6. Coat the propeller shaft with Quicksilver or Mercury Precision

Lubricants Anti‑Corrosion Grease or 2‑4‑C with Teflon.

Tube Ref No. Description Where Used Part No.

94

Anti-Corrosion

Grease

Propeller shaft

92-802867Q

1

95

2-4-C Marine

Lubricant with Teflon

Propeller shaft 92-802859A1

IMPORTANT: To prevent the propeller hub from corroding and

seizing to the propeller shaft (especially in salt water), always

apply a coat of the recommended lubricant to the entire propeller

shaft at the recommended maintenance intervals and also each

time the propeller is removed.

Loading...

Loading...