CYLINDER HEAD

90-857138R1 MAY 2000 Page 4A-19

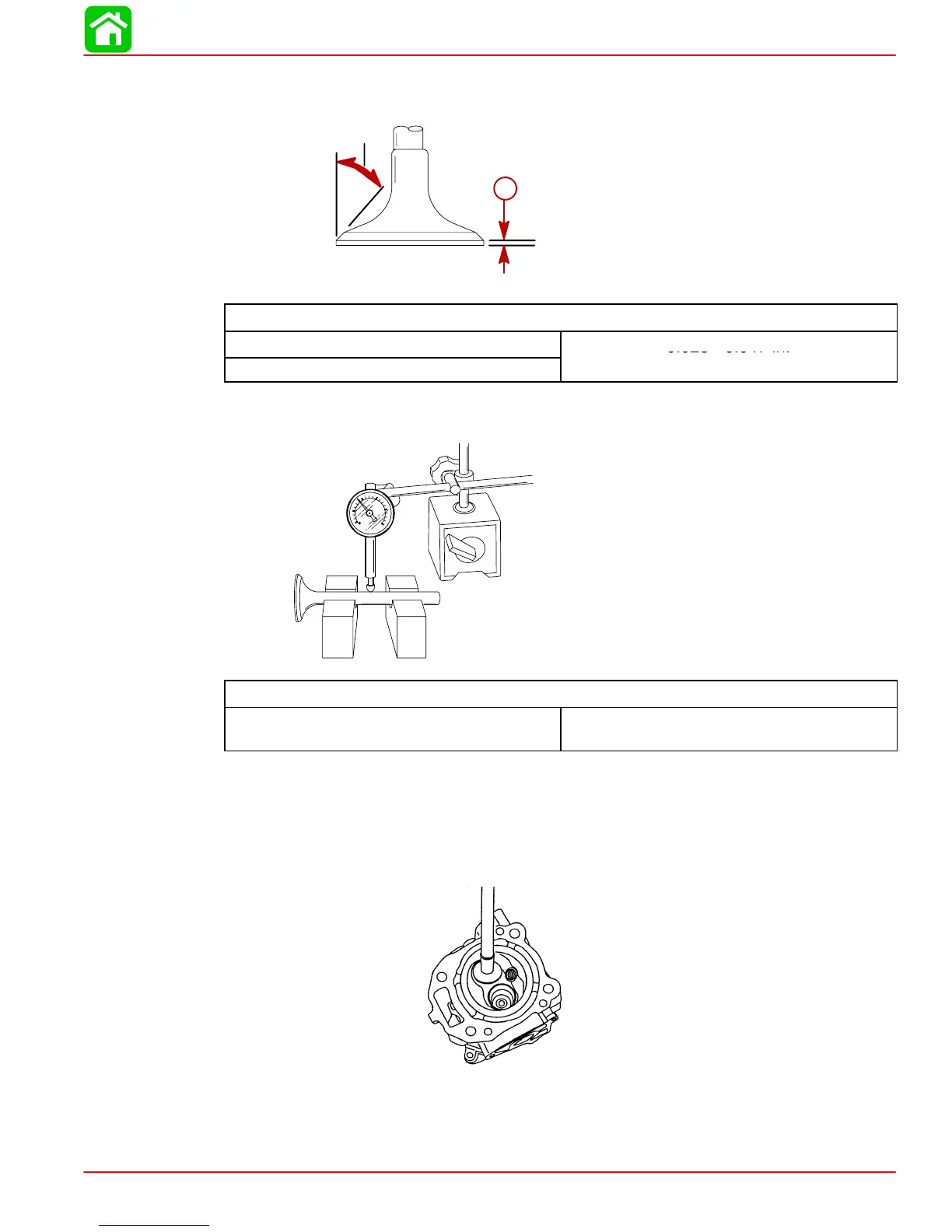

4. Check the margin thickness (a) of the valves after the valves have been ground. Any

valve with a margin thickness of less than the specification, should be replaced.

55809

45

°

a

Margin Thickness “a”

Intake Valve

0.028 - 0.047 in.

Exhaust Valve

(0.7 - 1.2 mm)

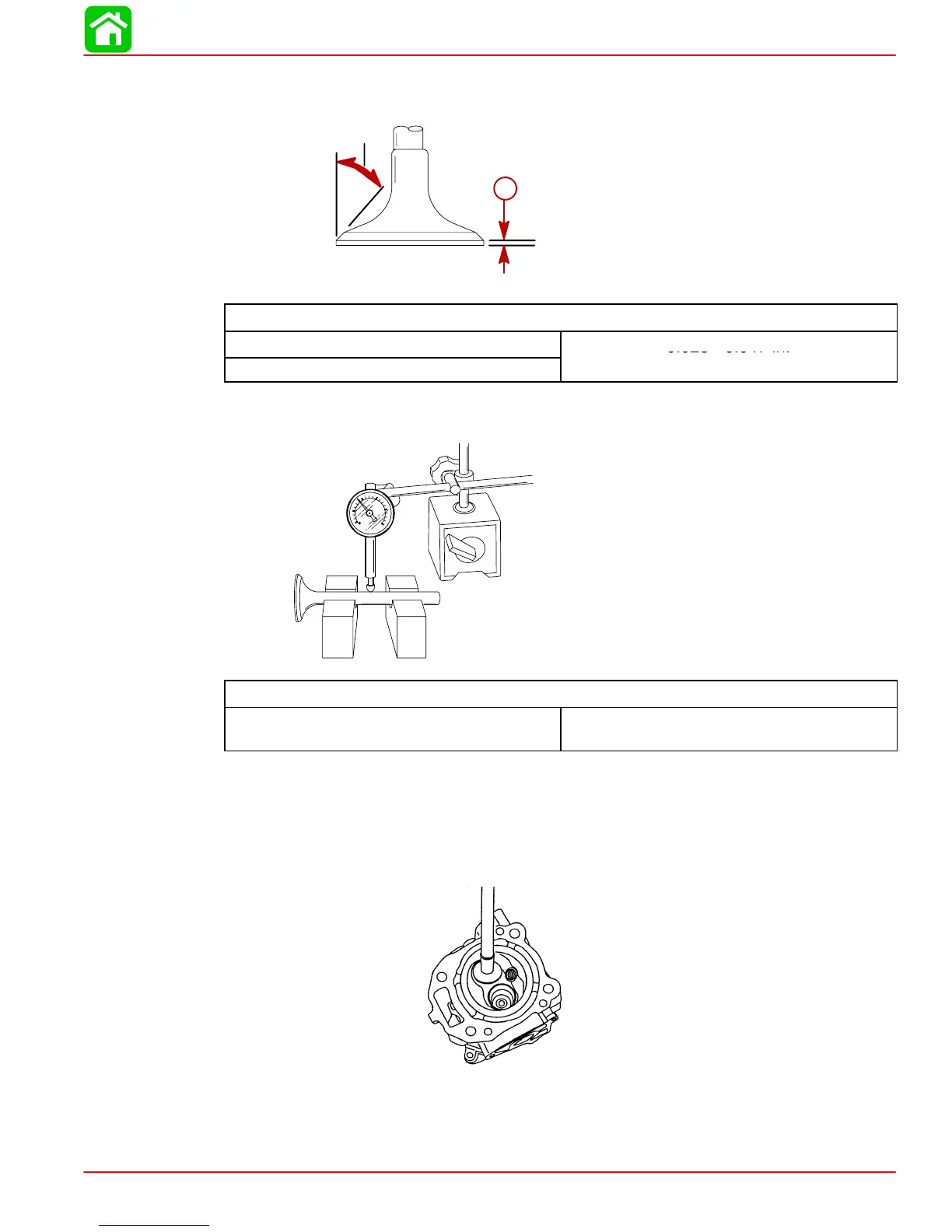

5. Measure valve stem runout, replace if out of specification.

55811

Valve Stem Runout Limit (Max.)

Intake Valve

Exhaust Valve

0.0006 in. (0.016 mm)

6. After repair of valve seat, lap the valve for proper fitting to valve seat.

7. Apply lapping compound to valve seat and lap valve while turning valve with valve lap-

per.

8. Apply lapping compound in 3 sequences; coarse compound first followed by medium

and then fine compound last.

IMPORTANT: Before using lapping compound of a different grade, completely re-

move previously used compound.

IMPORTANT: After lapping is complete, wash valve and valve seat removing all lap-

ping compound from them.

Loading...

Loading...