POWERHEAD

Page 4A-22 90-855347R1 JANUARY 1999

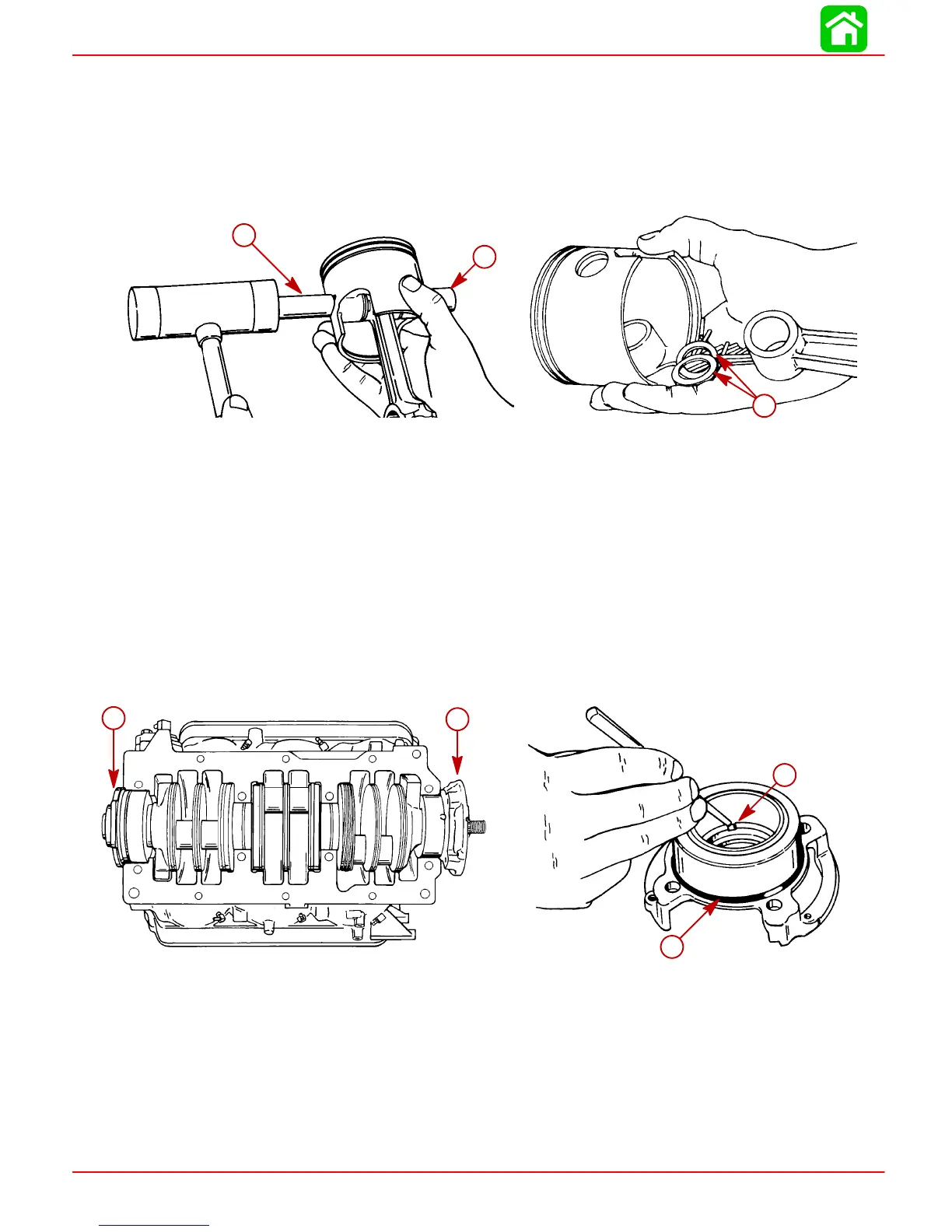

10. Support piston and tap out piston pin using service tool (91-76159A1) as shown.

11. Remove piston pin needle bearings (29 per piston) and locating washers (2 per pis-

ton) as shown.

IMPORTANT: We recommend that you use new needle bearings at reassembly for

lasting repair. However, if needle bearings must be re-used, keep each set of bear-

ings identified for reassembly on same connecting rod.

51088

51853

b

a

c

a-Piston Pin

b-Piston Pin Tool (91-76159A1)

c-Needle Bearing Locating Washers

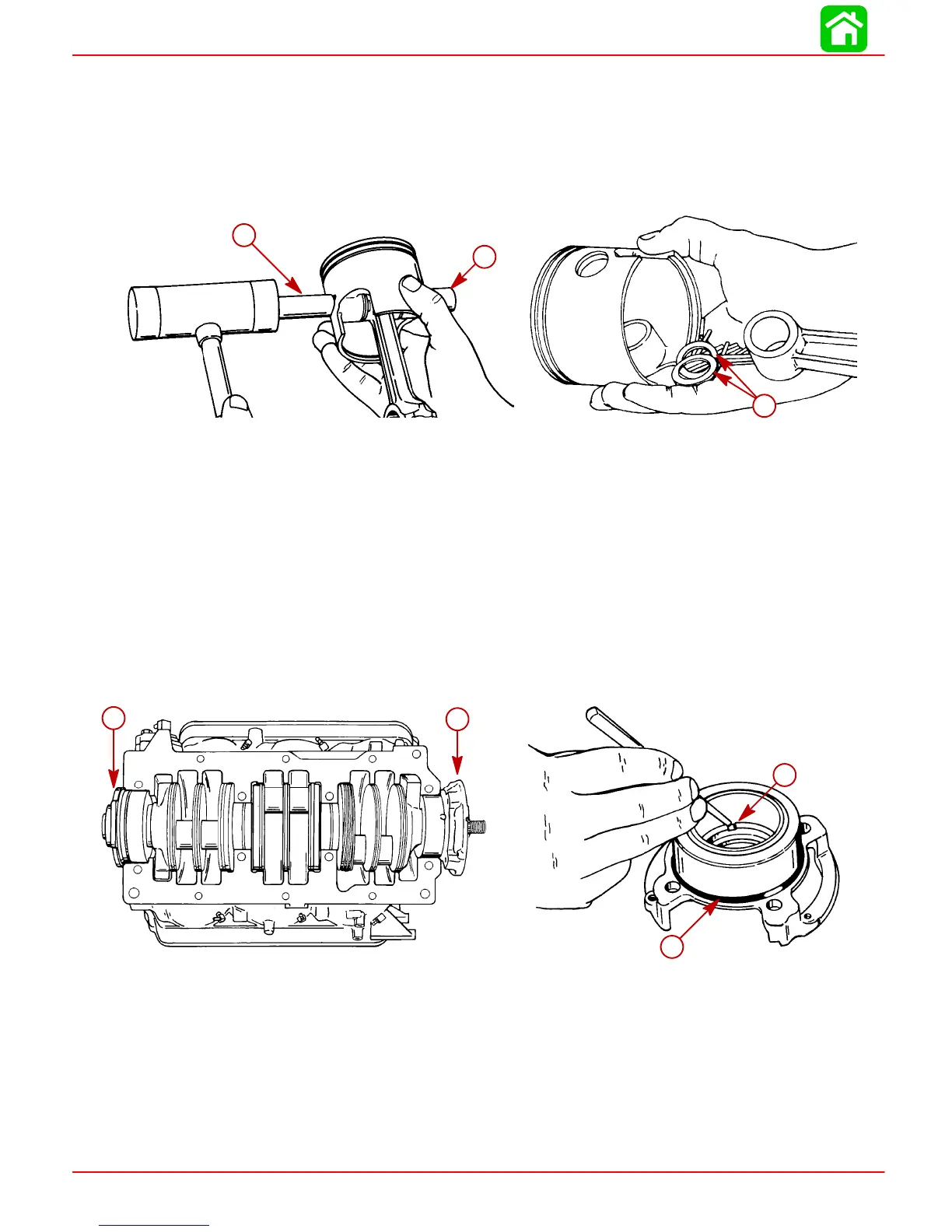

12. Remove upper end cap and lower end cap from crankshaft.

13. Remove and discard O-ring seals from each end cap.

14. Remove oil seal(s) from end of each end cap by driving seal out with a punch and ham-

mer.

15. Inspect roller bearing in upper end cap as outlined in “Cleaning and Inspection”.

NOTE: If roller bearing is damaged, replace upper end cap and roller bearings as an

assembly.

51853

c

d

51848

ab

a-Upper End Cap

b-Lower End Cap

c-O-Ring

d-Seal

Loading...

Loading...