RIGHT HAND NON-RATCHETING

90-855347R1 JANUARY 1999 Page 6A-23

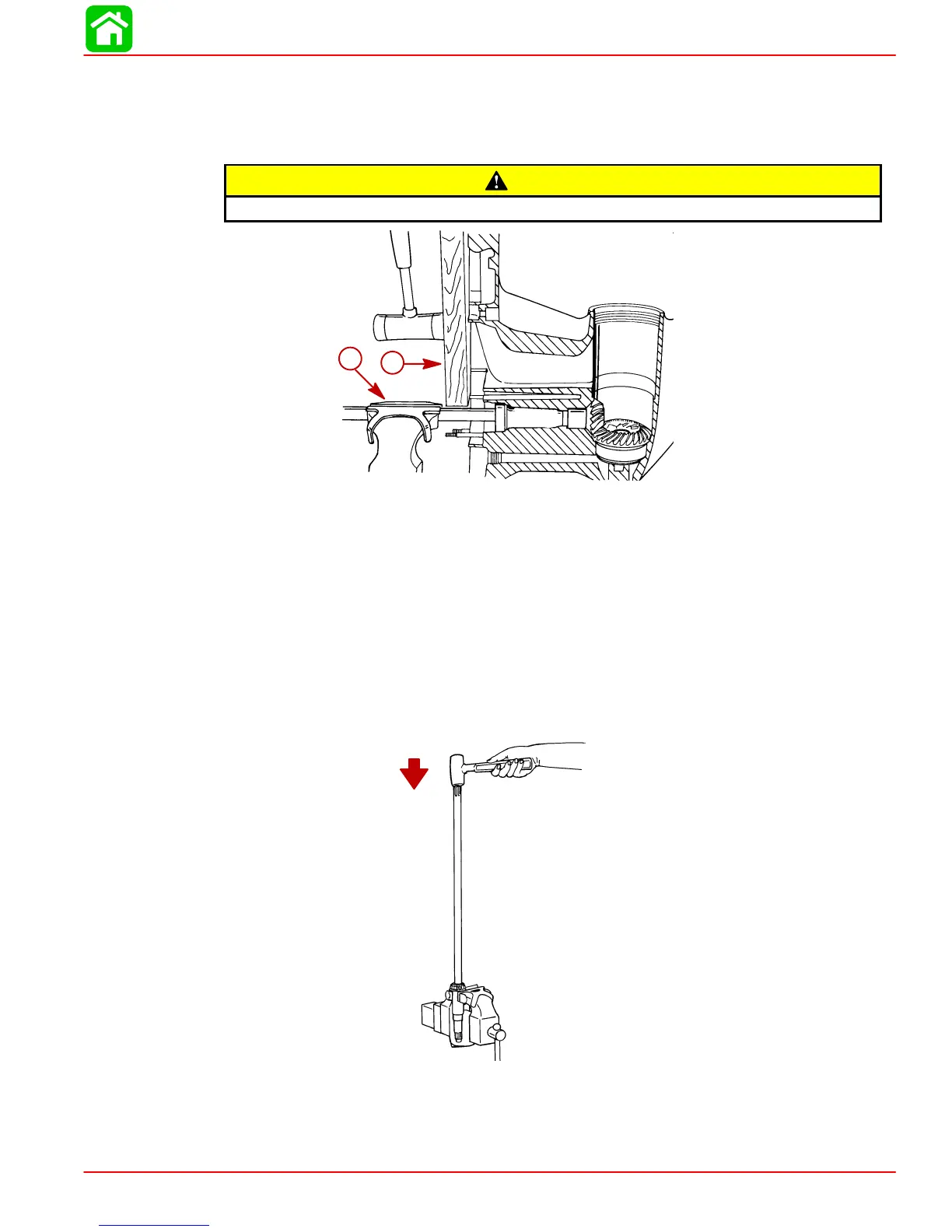

5. Remove gear housing from vise and re-position it as shown. Be sure to use soft jaw

vise covers and clamp as close as possible to water pump studs.

6. Place a block of wood on gear housing mating surface. Use a mallet and carefully tap

gear housing away from driveshaft.

CAUTION

DO NOT strike gear housing hard with the mallet or allow gear housing to fall.

51870

a

b

a-Wooden Block

b-Soft Jaw Vise Covers

7. Reach into gear housing and remove pinion gear and forward gear assembly.

8. After driveshaft is removed from gear case, remove and retain shim(s) that were lo-

cated under upper tapered driveshaft bearing.

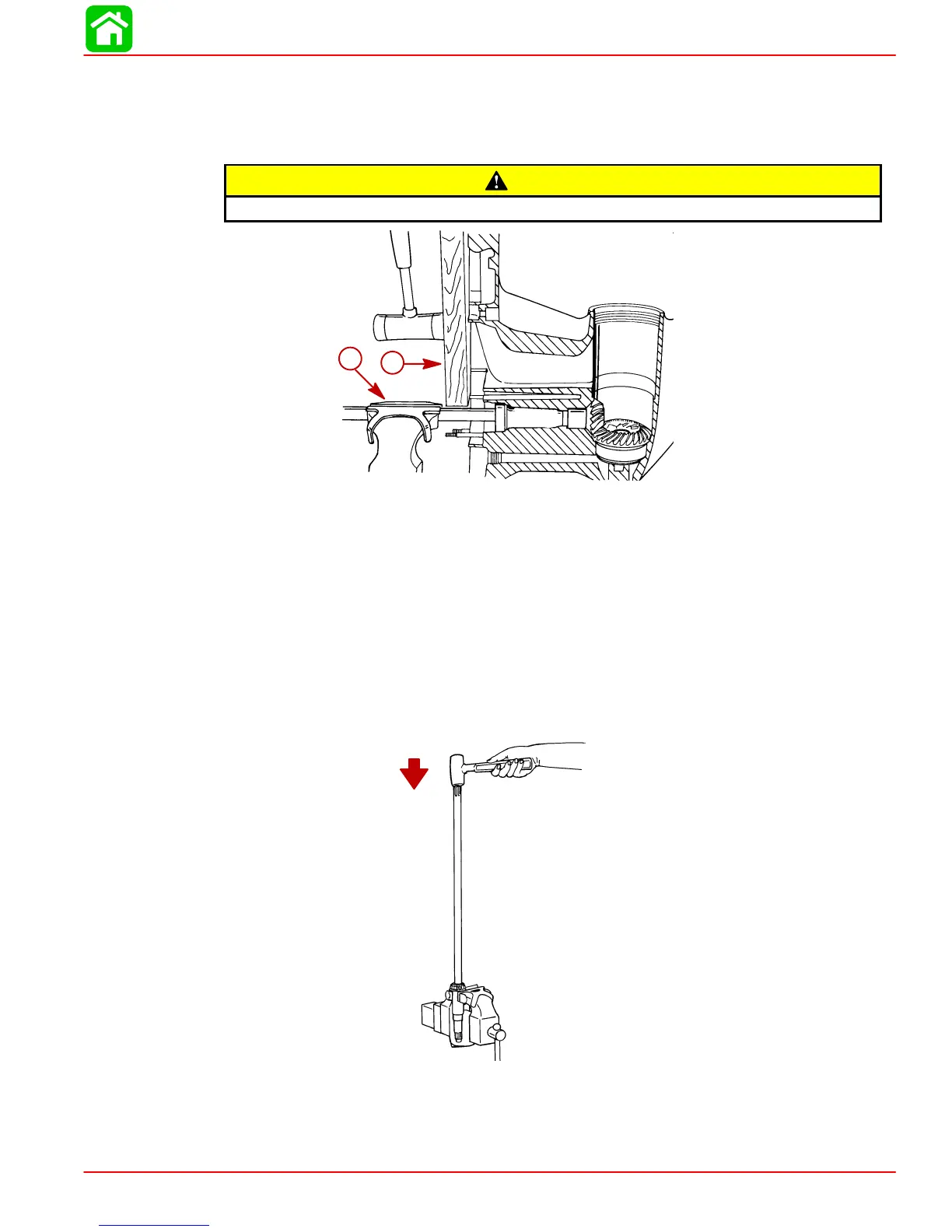

9. If inspection determines that replacement of driveshaft tapered bearing is required,

remove bearing from driveshaft as follows:

a. Position driveshaft in a vise; DO NOT tighten vise jaws against shaft.

b. Strike shaft with a lead hammer; take care not to drop shaft.

51866

10. Remove 18 loose needles from outer race of driveshaft needle bearing.

11. If inspection of driveshaft needle bearing surface determines that replacement of

needle bearing is required, the 18 loose needle bearings previously removed must

be reinstalled in bearing race to provide surface for mandrel to drive against.

Loading...

Loading...