Installation (cont.)

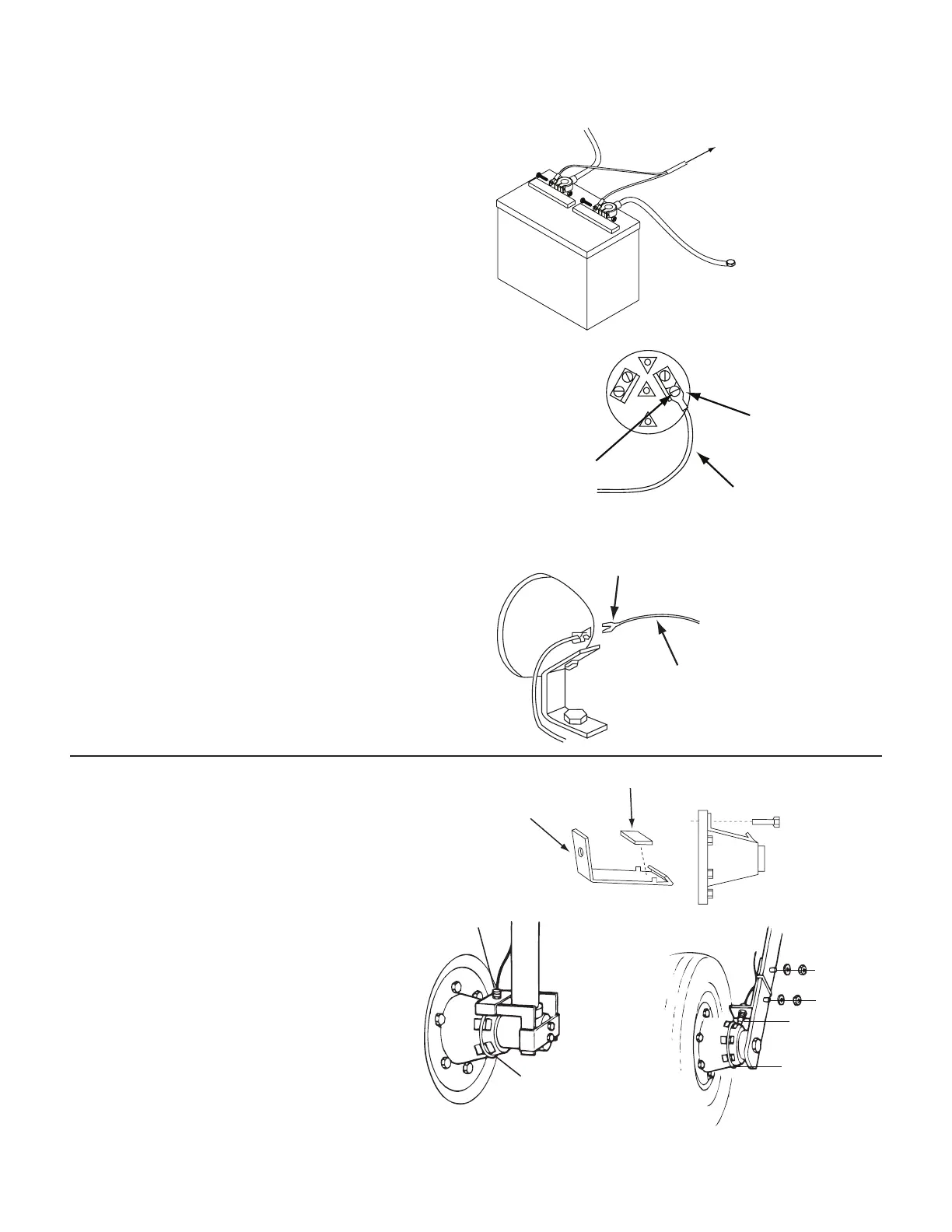

12 VDC Electrical Installation

Your MT-3000 will work on either positive or negative

ground 12 volt systems. Route wires away from hot engine

components, moving parts and high tension (spark plugs)

wires. Cut wires to proper length, crimping on appropriate

terminals and secure with plastic ties to prevent rubbing or

pinching.

STEP 1

Connect the ORANGE/BLUE jacketed cable to battery

using 5/16” insulated ring terminals. Orange connects to

“HOT” terminal and BLUE to chassis ground terminal. See

Illustration 3.

STEP 2

Connect single ORANGE wire to “ON” terminal of ignition

switch. Use a 12 volt test light to locate terminal which is

“HOT” only when switch is on. (Other possible locations

are hour-meter, fuel, tem or volt gauge.) NOTE: Do not

connect to ignition coil as console damage can result. See

Illustration 4.

NOTE: On dual battery 12 volt systems, all power wires

must be to the same battery. Connect the ORANGE/BLUE

cable (step 1) and then temporarily disconnect the other

battery before testing and connecting the single ORANGE

wire (step 2).

STEP 3

Connect single BROWN wire to lighting circuit. Some

possible locations include light switch, fuse black, headlight

or dash panel light. (This wire is for gauge light only and is

not required for proper operation of console. See Illustration

5.

10

+12VDC

HOT

ORANGE

BLUE

GROUND

(FRAME)

MT-3000

ORANGE/BLUE

Illustration 3

12 VOLTS WITH

SWITCH “ON”

SPADE TERMINAL

ORANGE WIRE

MT-3000

CH

Illustration 4

SPADE TERMINAL

BROWN

MT-3000

LIGHTING CIRCUI

Illustration 5

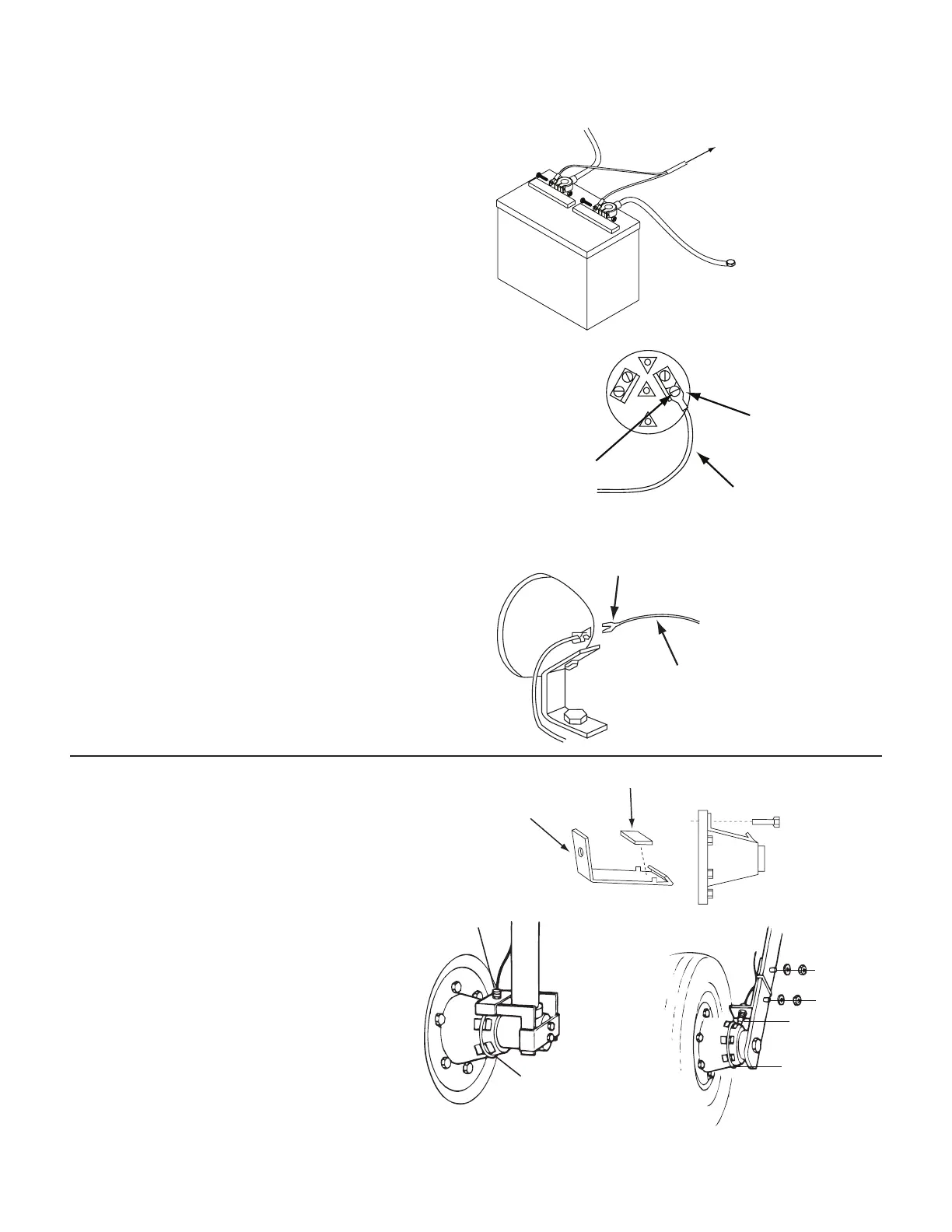

Magnetic Speed Sensor Installation

The speed sensor has a YELLOW cable tie near the connector

and mates with the main harness cable also having a

YELLOW tie near the connector. Make sure you install the

correct sensor.

Prepare magnet clips as shown. You may also

glue magnets directly to hub using epoxy or

other quality adhesive. Be sure magnets are

evenly spaced at least 2” (5 cm) apart or speed will

not be steady and spray rate will be erratic. We

recommend 1 magnet be installed for each wheel

bolt. Tighten cable ties as shown on next page.

NOTE: If the magnets are closer than 2” (5 CM)

apart their fields may interact causing erratic

operation. Correct this situation by using an even

number of magnets and reversing the polarity

of consecutive magnets. Use a test magnet with one side

marked to check polarity of each installed magnet. On

magnet should attract and the next repel.

DRILL LUG BOLT

HOLE AND BEND

TO FIT HUB.

MAGNET

Cable Tie

Tap thread for

bolts or weld

Speed Sensor

and Bracket

¼” Bolts,

Lockwashers

and Nuts

Speed Sensor

Cable Tie

Loading...

Loading...