Installation (cont.)

Plumbing - General

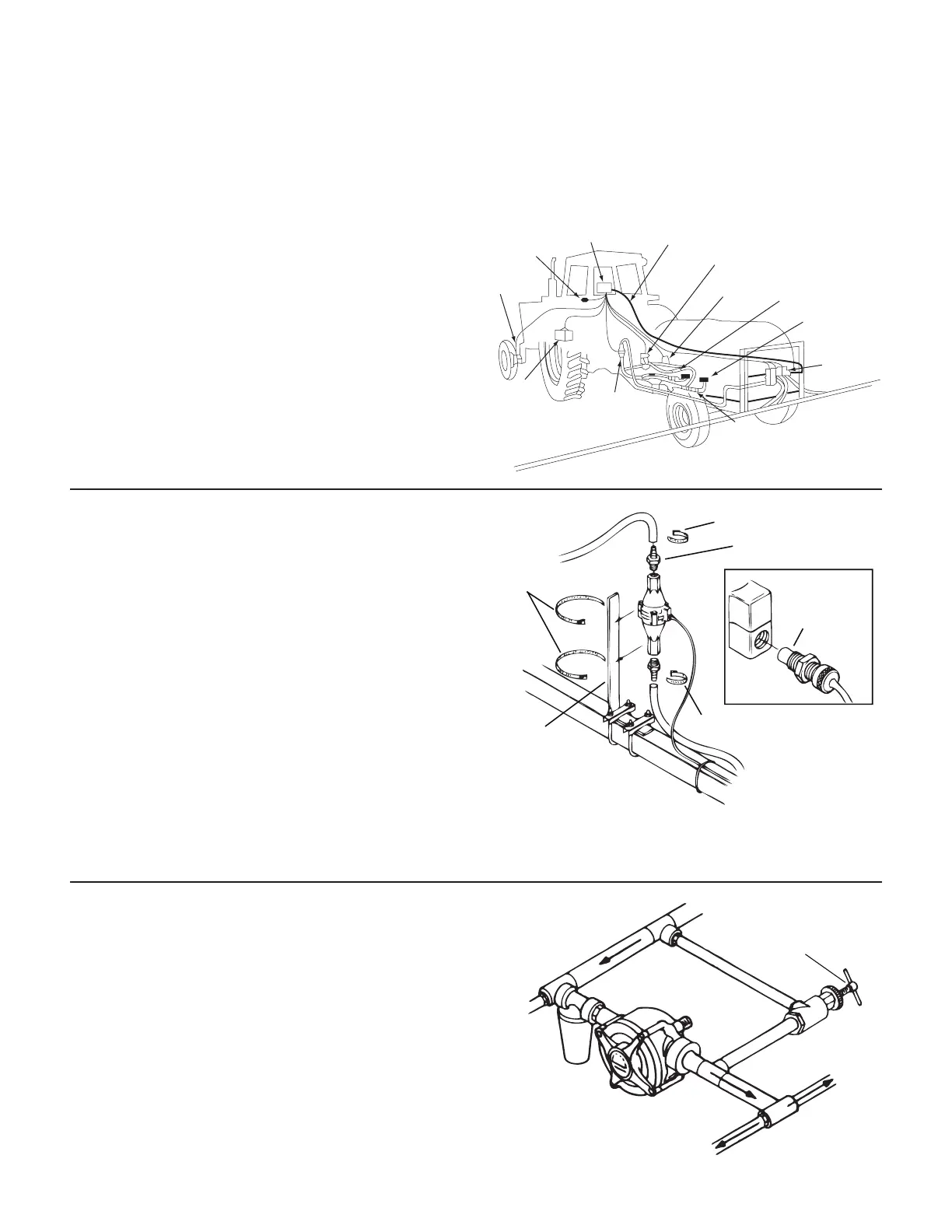

Refer to system diagram on page 6 for component

locations.

NOTE: Before beginning plumbing, make sure you have

the correct system. See Pre-installation section on page

9. Once installed, the servo or flowmeter can not be

exchanged for a different size.

FOR BEST PERFORMANCE AND UNIFORMITY OF SPRAY

1. Minimize use of elbows, tees, nipples, reducers or

anything else that restricts flow.

2. Use pump with enough capacity to handle flow to

nozzles, agitation line and servo valves.

3. Use pressure relief valve set at 60-80 PSI (4 - 5.5 bar)

on positive displacement pumps or centrifugal pumps

capable of more than 6.5 PSI (4.5 bar).

4. Pump output line should be 1” minimum.

16

SPEED

SENSOR

IGNITION

SWITCH

MT-3000

PRESSURE TUBING

BOOST SOLENOID VALVE

SERVO

VALVE

BOOST ADJUST

VALVE

AGITATION

INLET

SOLENOID

VALVES

MAIN

SHUT-OFF

FLOWMETER

BATTERY

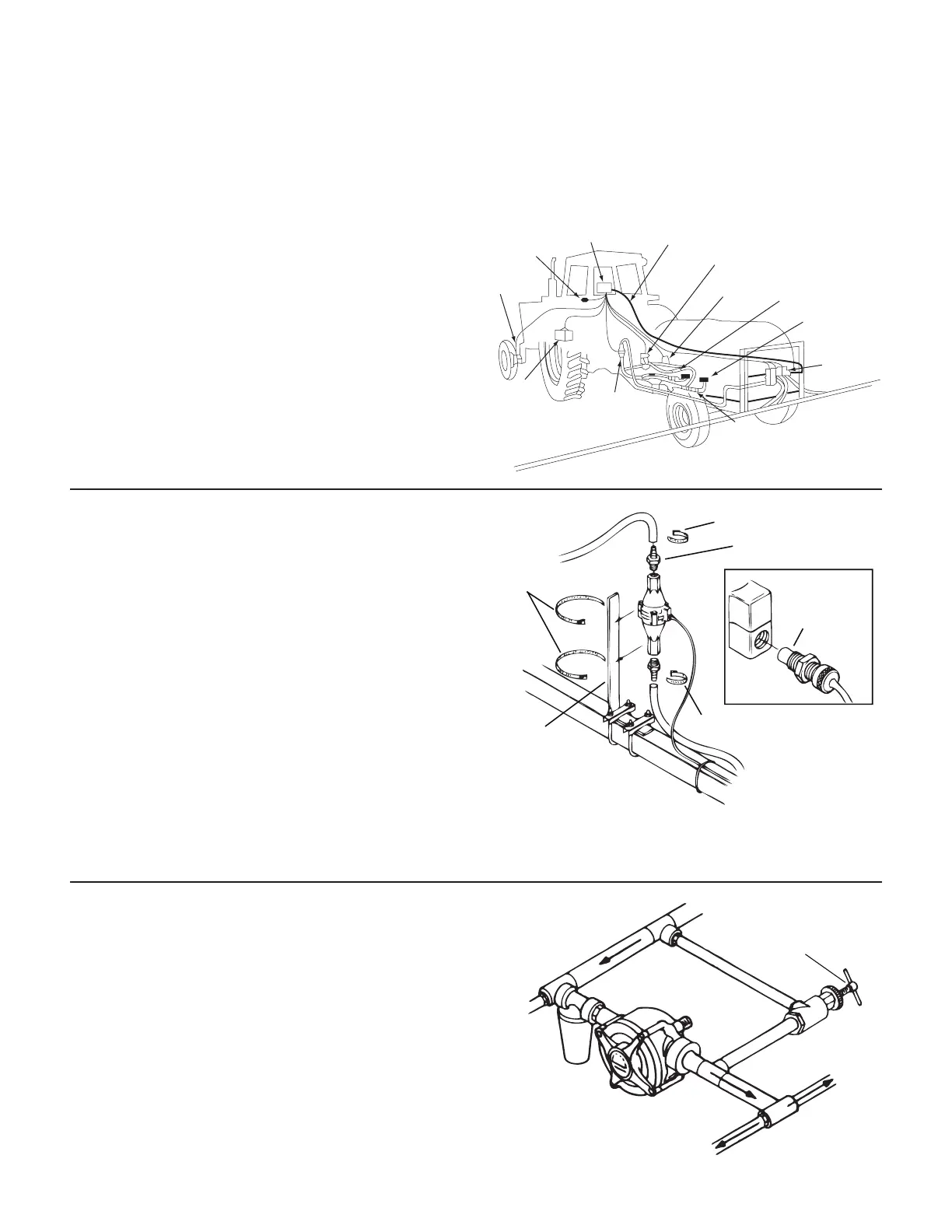

Mounting & Plumbing Flowmeter

1. Flowmeter must be installed at the pump output after

any strainers, return lines or valves. Securely mount

flowmeter (hardware not supplied) in an area away from

intense vibration in a vertical position. The flowmeter

may need periodic cleaning, there fore, it should be

easy to remove. Liquid can flow in either direction but

up is preferred. Make connections using ¾” fittings

without the use of reducers, elbows or sharp bends for a

minimum of 6” (15 cm) either side of the meter.

2. Apply a small amount of grease to the sensor threads and

screw sensor all the way onto hole of flowmeter. The flow

sensor has a GREEN cable tie near the connector which

mates with main harness cable also having a GREEN tie

near the connector. Tighten 3/8” jam nut to lock sensor

in place. Secure cable with plastic ties.

NOTE: Save plastic plugs to protect flowmeter during

storage.

Sprayer Line*

Locknut

Sensor

(green body)

Flowmeter

* NOT SUPPLIED

“L” Bracket*

Hose Clamps*

¾” NPT Male Fitting*

Hose Clamps*

Hose Clamps*

Pressure Relief Valve

If you have a positive displacement pump or a centrifugal

pump capable of more than 65 PSI (4.5 bar) you must install

a pressure relief valve and adjust it to a safe maximum

pressure. NOTE: See Plumbing Guidelines on page 32 for

adjustment procedure. If a positive displacement pump is

operated without a pressure relief valve, damage may result

to pump or other plumbing component.

For positive

displacement pumps

Tee “C”

Tee “A”

Pressure

Relief Valve

5. For pumps rated above 50 GPM (190 lpm), use 1½”

suction line and 1¼” servo valve return line. Plumb

return line into pump inlet or back to tank (not

agitation). Line must have unrestricted flow.

6. Boom having flow greater than 5 GPM (19 lpm) should

use ¾” lines minimum.

NOTE: See Plumbing Guidelines on page 32 for additional

information.

Loading...

Loading...