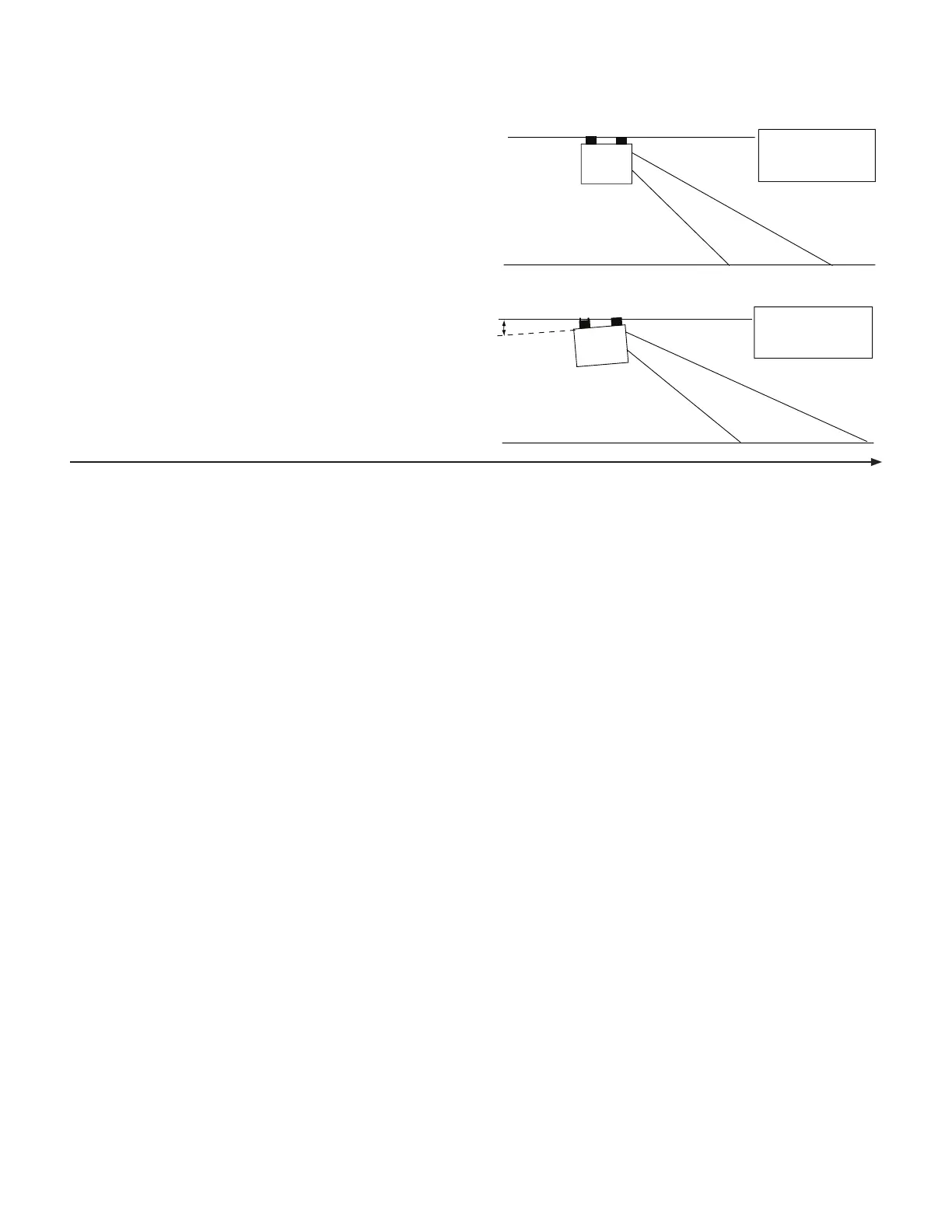

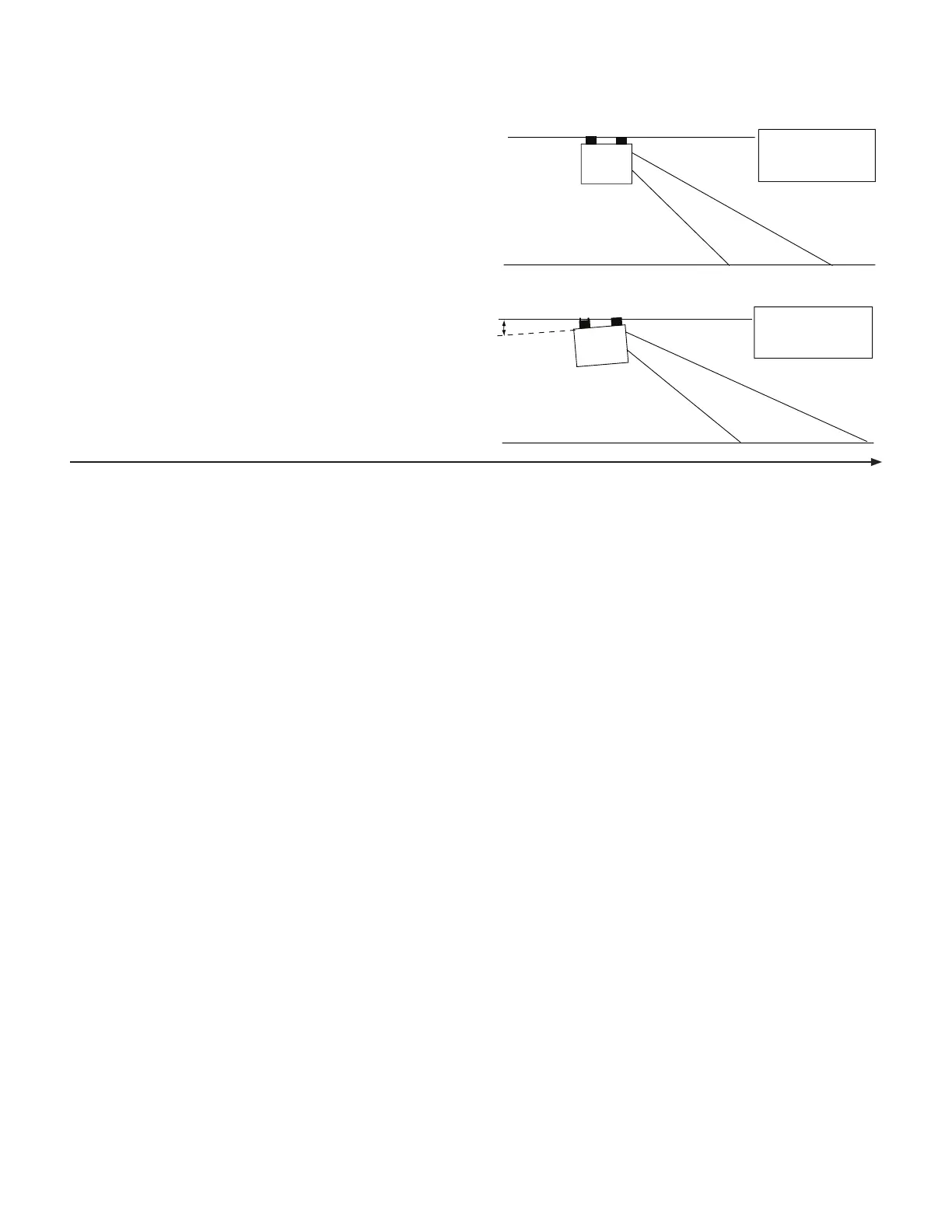

EXAMPLE:

NORMAL LEVEL MOUNTING POSITION

MOUNTING POSITION ADJUSTED TO

RAISE HORN END 8°

8°

DISPLAY READS

DISPLAY READS

SPEED

SPEED

5.0

5.5

If under actual field conditions you find that your speed

measurements (or distance) is consistently off, as determined

by another independent measurement, you can fine-tune

the system by following the speed calibration instructions

for your particular monitor/controller and increasing or

decreasing the speed calibration value by a small amount

and then rechecking the accuracy. Repeat as necessary until

true readings are achieved.

NOTE: With some systems, the speed calibration value

can not be adjusted with the console. In these cases,

adjustments to the speed measurement can be made by

slightly raising or lowering the horn end of the Trak-Star.

For each degree of angle that the horn is raised, the console

display will show an increase in speed of 1.3%. Likewise for

each degree that the horn is lowered, the speed will show

a decrease of 1.3%.

Installation (cont.)

Trak-Star Ultrasonic Speed Sensor (cont.)

Calibration Adjustments

Troubleshooting

NO SPEED

Trak-Star should emit a “crackling sound”. If not, check for

12 volts between pins A and B of the adapter cable six-pin

connector. If 12 volts is present but Trak-Star does nor

crackle, Trak-Star is defective. If there is no power from A and

B, check cable and connections.

Use a jumper wire (paper clip bent in a “U” works well)

and several times rapidly short together pins E and F of

the adapter cable. If console responds with some SPEED

reading, console and adapter cable are OK and the problem

may be in Trak-Star. If console will not respond, problem

may be in console or adapter cable.

SPEED ERRATIC, INTERMITTENT, SLOW TO RESPOND

OR NO SPEED AT ALL

This can be a result of echo interference when mounted

under vehicle. Move Trak-Star all the way to front and

pointed forward or all the way to rear and pointed rearward.

Remember to avoid chemicals and plant stalks.

Some ground surfaces (hard packed dirt or gravel; soft,

smooth sandy or powdery soil; some asphalt and concrete;

etc) may cause weak signals. If you experience erratic

operation under any of these conditions, try a lower mount

height.

Dirty Foam - Dust can usually be removed by tapping on the

foam. For anything other than dust, the foam will have to be

thoroughly washed.

Remove the foam and thoroughly clean it with soapy

water. (The foam can be removed without unscrewing the

retaining bracket. Completely rinse the soap and squeeze

out the water. Re-install the foam and check sensor

operation. The Trak-Star may also not function properly if

excessive moisture is present on the foam.

In some extreme conditions where marginal signal is

present, the foam may cause erratic operation. The Trak-

Star can be used without the foam. However, extreme care

must be exercised, especially in windy conditions, or in

fields with vegetation tall enough to contact the Trak-Star.

It would be better to leave the foam in place and relocate

the Trak-Star to a more suitable location.

Dirty transducer or holes in transducer membrane. Gently

flush horn with water and pat dry with soft cloth. (Do not

use high pressure or compressed air.) For oil or chemical

contamination, you may use an automotive aerosol brake

cleaner or aerosol electronic contact cleaner. If crackling

quits and will not come back within a minute or two, the

transducer membrane has been damaged and must be

replaces. NOTE: Do not use base ph liquids on transducer.

When driving over standing water or smooth wet surfaces,

the signal from the sensor may be deflected, resulting in a

temporary loss of speed measurement. Speed readings will

resume once the wet area has been passed.

Poor Ground - Run the Trak-Star’s blue ground wire direct to

the battery or the battery cable at the engine block.

SPEED READING WHILE STOPPED

Occasional reading of up to .5 MPH (1.2 kph) while stopped

may occur, especially when in or around buildings or other

machinery.

Echo interference from inadequate installation may cause

speed reading while stopped. Relocate the Trak-Star if this

occurs.

SPEED STEADY BUT INCORRECT

If the six-pin connector is mated with power applied, the

Trak-Star may program for the wrong monitor. Cycle power

after the six-pin connector is mated.

The six-pin connector of the Trak-Star is labeled A-F. Positions

C and D program the Trak-Star for the appropriate monitor.

If the wires to C or D are broken, pulled out or shorted, the

Trak-Star may be incorrectly programmed.

On monitors with adjustable speed calibration, fine-tune

calibration as needed to get correct speed. On monitors

without adjustable calibration, fine-tune speed by making

small changes in Trak-Star mounting angle.

15

Loading...

Loading...