11

Installation (cont.)

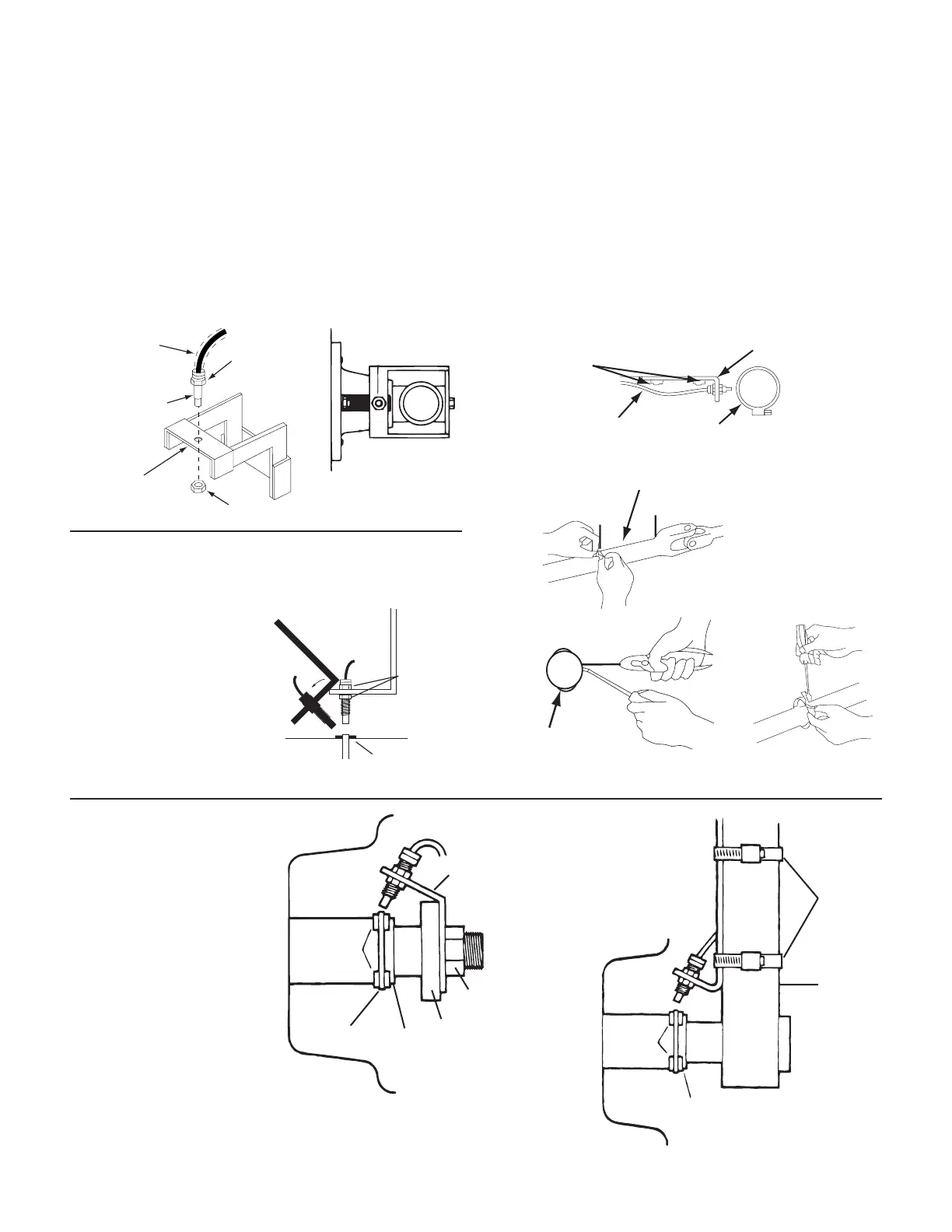

Mounting Bracket

Cut and bend as required. Rigidly mount using ¼” bolts, self-

tapping screws or by welding. NOTE: Always disconnect

console before welding on equipment.

If the “L” bracket will not fit as in the implement wheel

examples, you may fabricate one as shown using a minimum

of materials. Do not attach bracket to the spindle housing

or any other part which does not maintain power alignment

while turning. Bracket must be securely mounted.

Hub

Top View

Sensor

3/8” nut

Optional section

of hose to

protect cable

3/8” nut

3/8” hole

for sensor

DRIVE SHAFT

DRIVE SHAFT

VEHICLE EQUIPMENT FRAME

¼” BOLTS OR

SELF-TAPPING SCREWS

SENSOR CABLE

12” (30 CM) MAXIMUM from U-JOIN

Sensor Adjustment

Unthreaded tip of sensor

must extend beyond

locking nut. Adjust sensor

for approximately ¼” (.6

cm) air gap from tip of

sensor to cable tie of hose

clamp adjusting screw.

Sensor may be angled up

to 45 from perpendicular

but must be directly over

magnets.

45° max

Sensor

(Green body)

3/8” nuts

be rigidly

mounted

be mounted more than

45° from perpendicular

¼” to ½” air gap

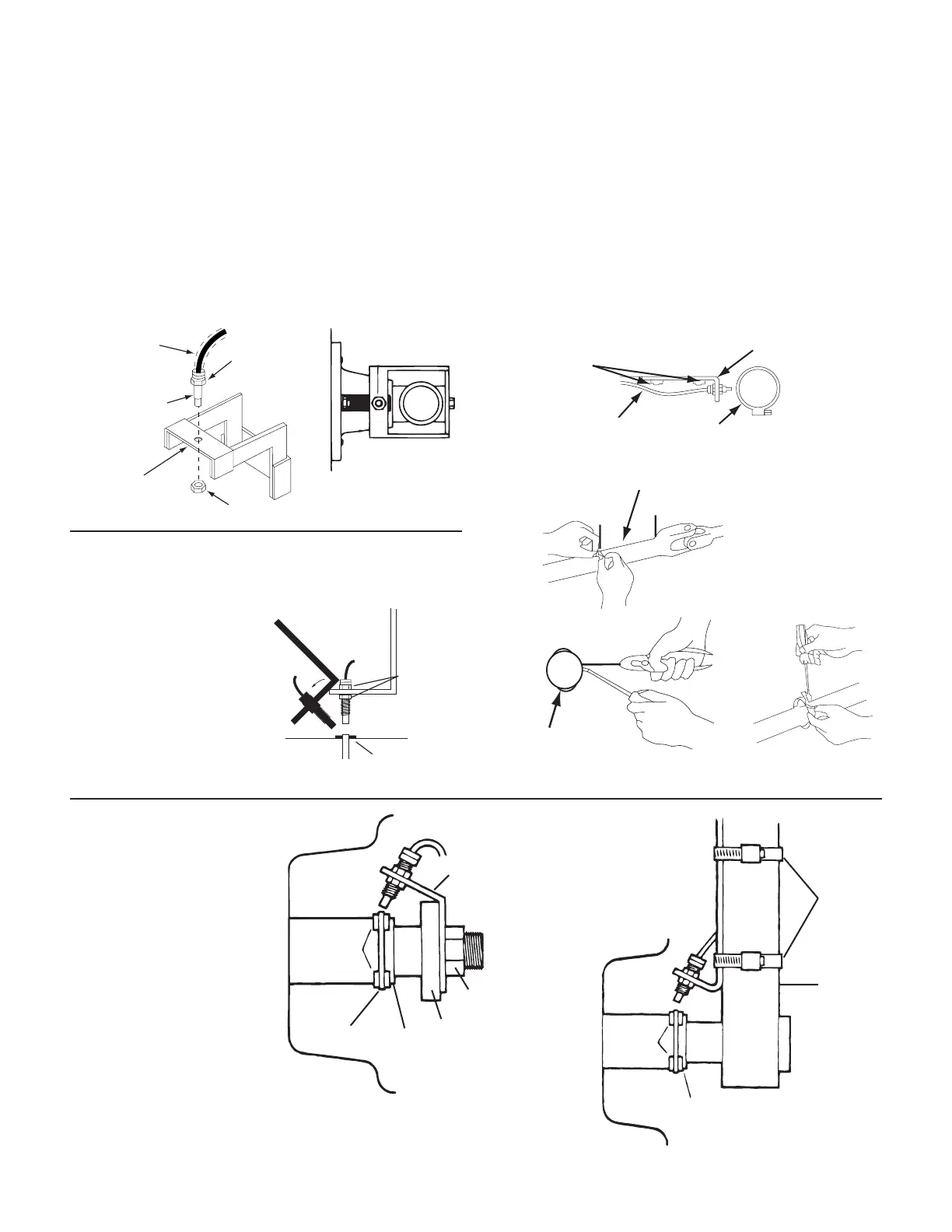

Drive Shaft Installation

Use this installation on pickups, 4-wheel-drive tractors,

planters, etc.

Locate sensor mount bracket on frame near transmission,

transfer case or hanger bearing, where drive shaft has

minimum up/down movement.

Secure two (2) magnets on drive shaft (with long dimension

in direction of rotation, exactly opposite each other, and at

least 2” (5 cm) apart using either cable ties or hose clamp

(not provided) as shown. NOTE: If using hose clamp,

position adjusting screw between magnets. Hose clamp

must be non magnetic stainless steel.

USING HOSE CLAMP

ATV Installation

Follow the same basic

procedures as implement

wheel installation but refer to

the following Illustrations for

mounting locations on front

wheel.

CAUTION: Sensor should be

installed on side of wheel

without valve stem to avoid

possible interference.

Sensor Bracket

Axle

Nut

Swing Arm

Hub

Rim

Plastic

Cable

Tie

Magnet

Cut Bracket

to Clear Rim

Cut and Bend

Bracket as

Required

Metal

Hose

Clamps

Fork

Tube

Axle

Hub

Rim

Magnet

Loading...

Loading...