Installation (cont.)

General Installation

YOUR SPRAYER

All the components of your sprayer must be sized correctly

and in good working order. Plumbing Guideline on page 32

will give you some suggestions, but the details on proper

plumbing are basically beyond the scope of this manual.

Nozzle manufacturers offer detailed application literature

which includes valuable technical information. The MT-3000

will make a properly designed system perform far better than

any manually operated system. The MT-3000 can not make

a poorly plumbed system perform properly and may cause a

marginal system not to operate at all. You sprayer dealer and

chemical supplier want you to be successful and will assist in

selecting proper equipment.

SPRAYER PLUMBING

Remove all valves and regulators not shown in the system

diagram. See page 8. For ease of use and to maximize the

benefits of your MT-3000, you should replace manual boom

valves with electric solenoid type valves.

WELDING

Unplug the wiring harness from your MT-3000 console

before doing any welding on your equipment.

EXTENSION CABLES

Enough cable is provided for typical sprayer applications

such as pickups, high-boys, 3 point hitch, etc. If you need

more length 5’, 10’, 15’ and 20’ extensions are available.

TIPS ARE THE KEY

Many sprayers today are operating with wrong size, worn,

damages, clogged or improperly installed spraying tips.

Make sure your tips are correct and in good condition.

CAUTION: Never put chemicals in your sprayer until it has

been completely checked out with water to verify proper

operation.

9

Mounting the Display Console

Select a mounting location which seems most workable,

and best fits your needs. It should be convenient to reach

and highly visible to the operator. DO NOT INSTALL IN

A POSITION THAT OBSTRUCTS THE VIEW OF THE ROAD

OR WORK AREA. Whenever possible, avoid locations that

expose the console to direct sunlight, high temperature,

strong chemicals or rain.

NOTE: Route wiring harness away from sharp edges, heat,

moving parts or area of operator movement. Allow enough

slack at hitch connections for turning.

Make a ground wire using an 8” (20cm) length of 14 GA.

BLUE wire. Crimp a female tab terminal on one end and a

¼” ring terminal on the other end.

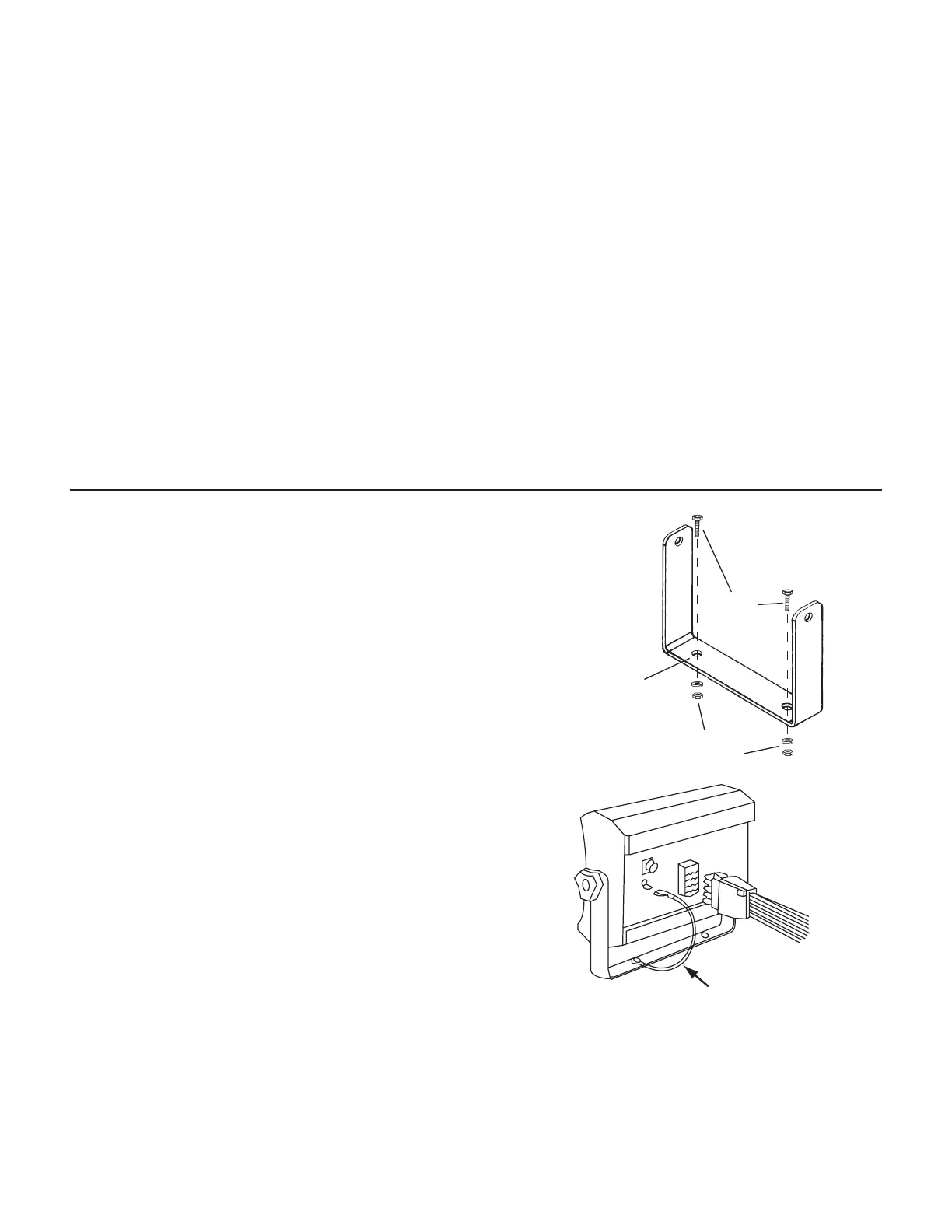

Mount console bracket and one end of ground wire on a

flat rigid surface using the ¼” bolts or self-tapping screws

provided. See Illustration 1.

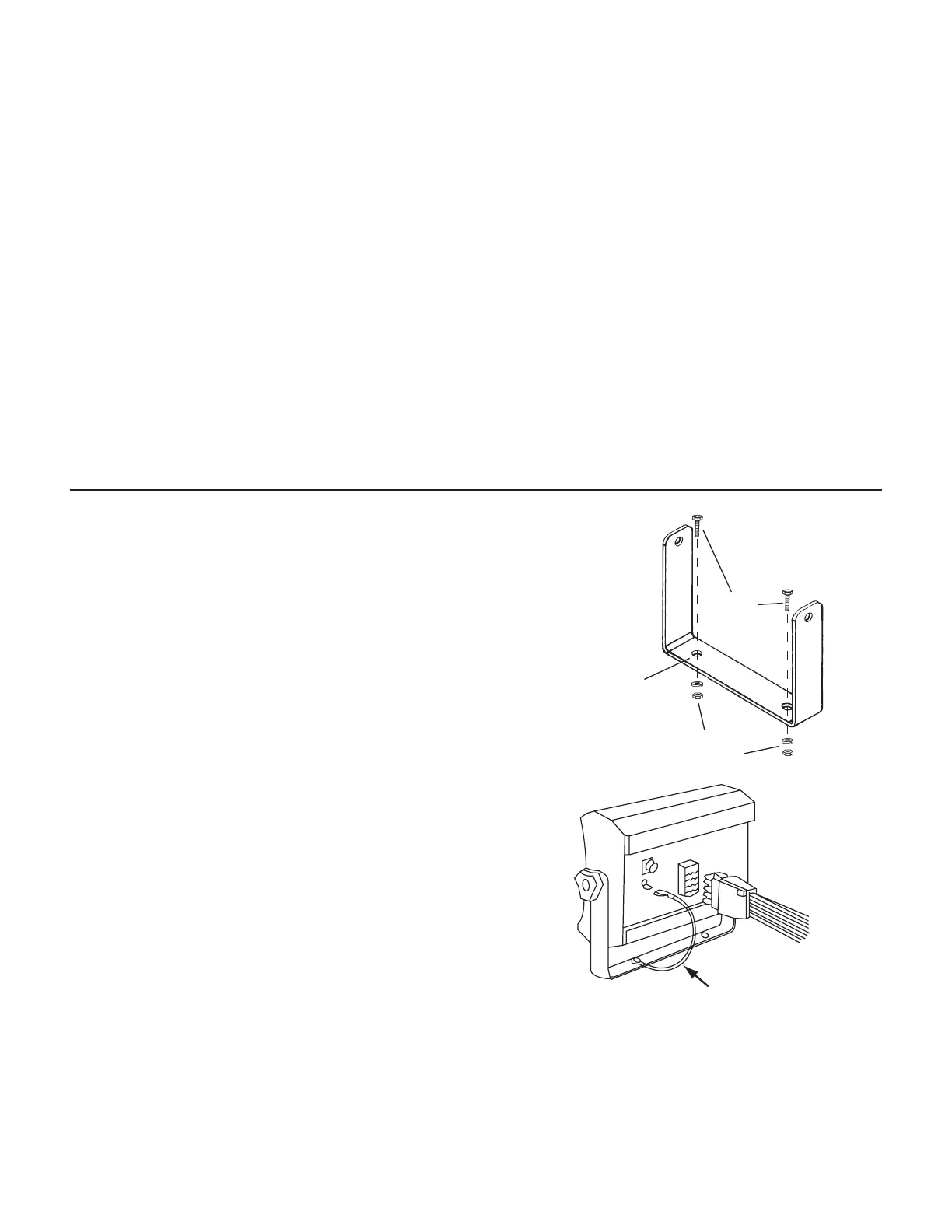

Insert mounting knob through “U” bracket and rubber

washer. Rubber washer will hold knob in place while

installing the console. Insert console and secure with

adjusting knobs. Connect ground wire terminal on console.

See Illustration 2.

Drill ¼” (7mm)

holes for bolts,

or 3/16“ (5mm)

holes for self-

tapping screws.

Bolts

Lockwashers

and nuts

Illustration 1

GROUND WIRE

Illustration 2

Loading...

Loading...