Installation (cont.)

Trak-Star Ultrasonic Speed Sensor (cont.)

Installation (cont.)

3. Plug adapter cable into connector on Trak-Star and

permanently mount sensor with flat washers, lockwashers

and hex nuts. The blue wire on the Trak-Star cable and

MT-3000/5000 adapter cable must be attached to the

frame making sure there is good metal to metal contact.

The wires may be attached to one of the mounting bolts

or any other convenient screw or bolt. Cut blue wires to

appropriate length and attach ring terminals provided.

4. Remove backing from decals provided and place

over unused mounting channels to prevent dirt

accumulation.

5. Run the adapter cable to the control console’s speed

sensor cable, avoiding other electrical wiring and areas

of high heat or abrasion. Secure cable along entire

length with cable ties. DO NOT plug cables together

until calibration is complete.

NOTE: See calibration information on the next page for

additional calibration information.

Adapter Cables

By substituting the appropriate cable for the MT-3000/5000

cable supplied, the Trak-Star ultrasonic speed sensor may

also be used with a variety of other makes and models of

controllers and monitors including: Micro-Trak, Calc-An-

Acre, Flow-Trak, Yield-Trak, Dickey-john, Gandy DAS, Hiniker,

Magnavox, Raven and SED/Field Electronics.

GENERAL INFORMATION

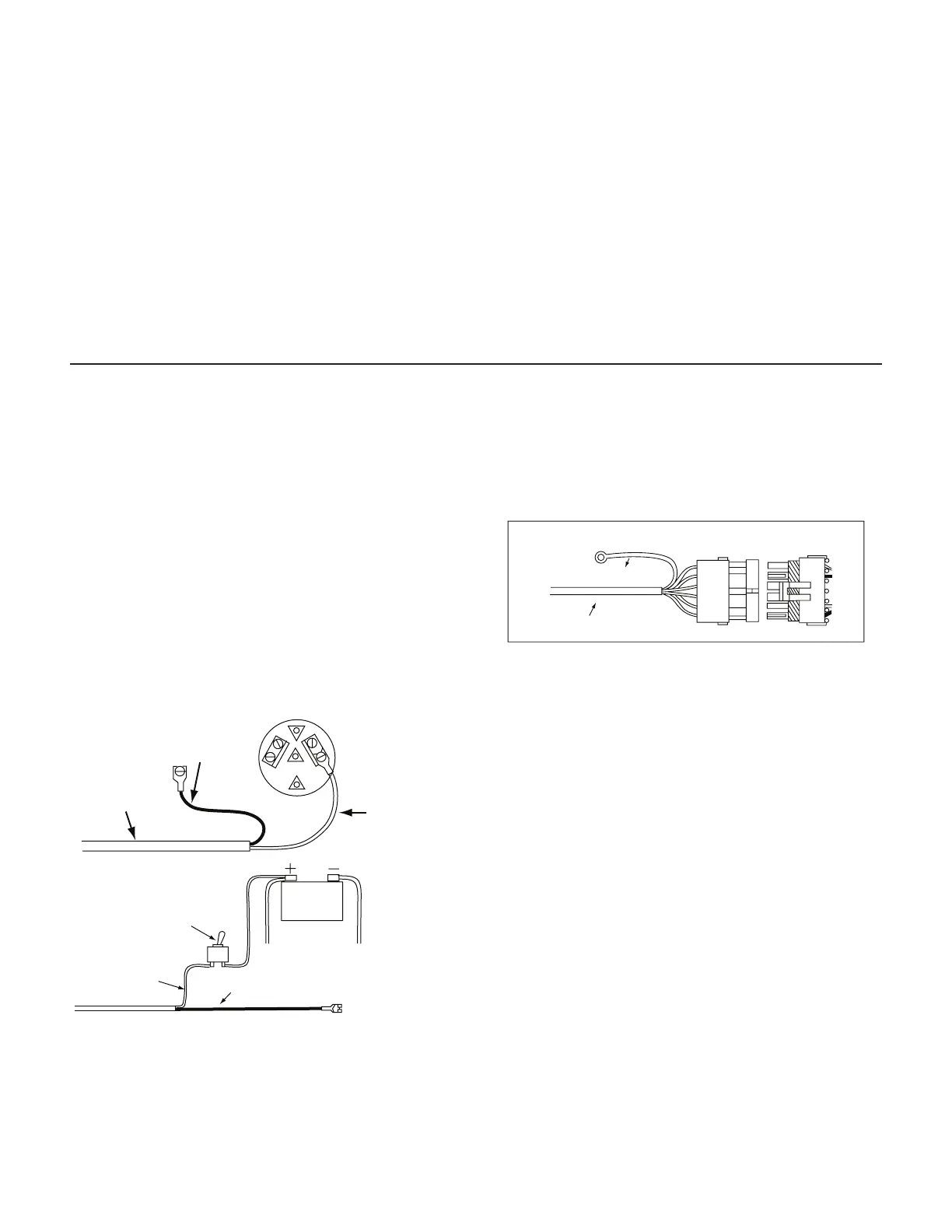

1. All adapter cables are equipped with a six pin connector

for direct connection to the Trak-Star and an appropriate

mating connector on the other end to plug into the

monitor/controllers standard speed input cable.

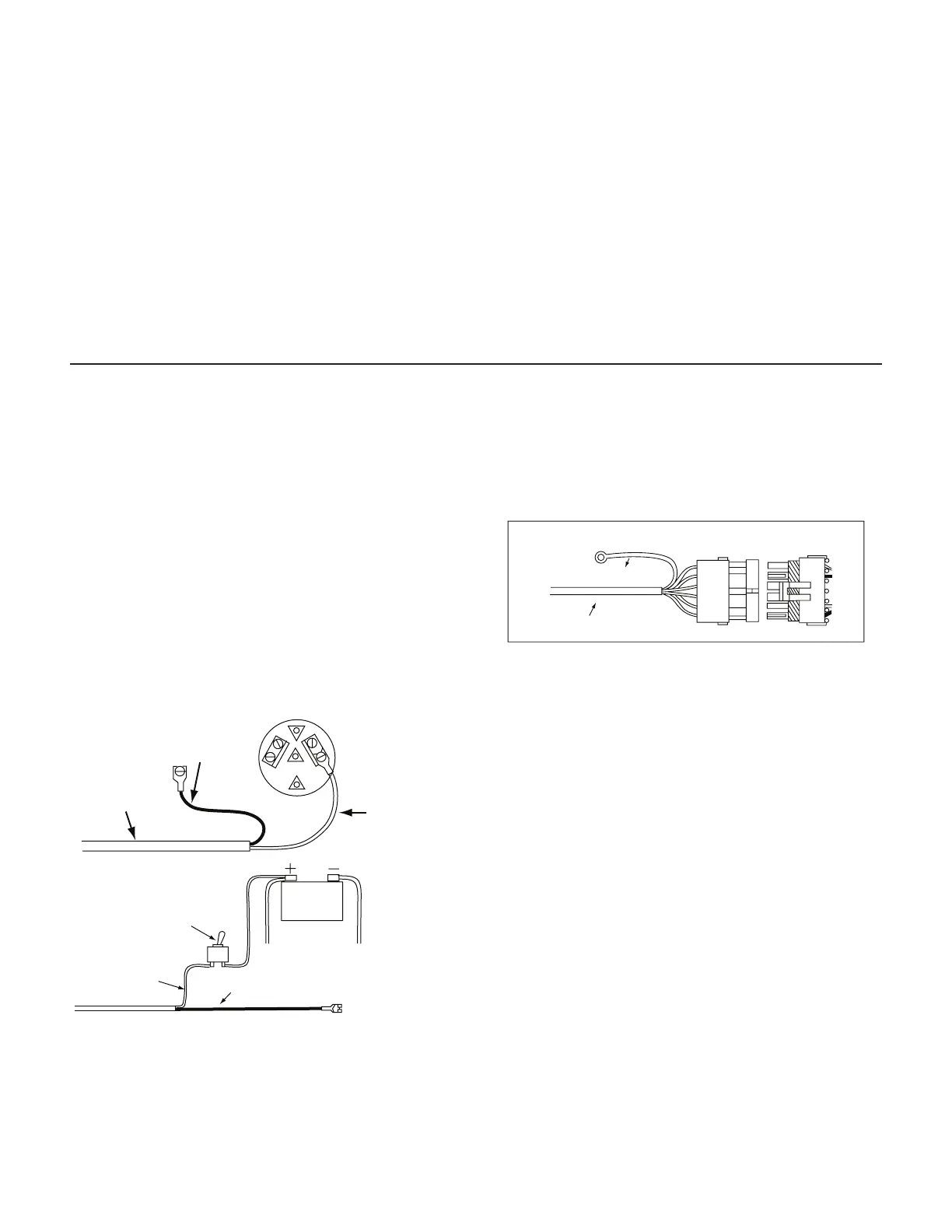

2. The adapter cables for units which do not provide a

power source for the speed sensor have an attached tow

conductor power card which must be connected to the

tractor or vehicles’s 12 VDC power system.

BLACK WIRE

TO FRAME (GROUND)

POWER CORD

RED WIRE TO

TERMINAL OR

LEAD WIRE

THAT IS “HOT”

WITH IGNITION ON

ON/OFF

POWER SWITCH

12 VDC

BATTERY

RED WIRE

BLACK WIRE TO FRAME (GROUND)

Cut power cord to appropriate length and strip 3/8” (1 cm)

of insulation from the end of each wire and attach spade

terminals provided (or other connectors is desired).

3. In all cases the blue wire from the Trak-Star must be

attached to the equipment frame (ground).

NOTE: GROUND CONNECTION (ALL UNITS)

BLUE WIRE TO FRAME (GROUND)

TRAK-STAR CABLE

14

Care and Maintenance

1. Always cover or remove the Trak-Star before traveling at

highway speeds. Flying rocks, road sand and bugs can

damage the transmitter/receiver. Physical damage IS

NOT covered by the factory warranty.

2. Trak-Star’s case is watertight under normal weather

conditions and washing. However, do not subject the

unit to steam or pressure cleaning.

3. Keep the transmitter horn free of dirt and mud. The horn

should be cleaned with low pressure water or an aerosol

automotive brake cleaner or electronic contact cleaner.

DO NOT use base ph liquids on horn. DO NOT insert

screwdrivers or other sharp objects into the horn.

4. When cable are disconnected, plug in the protective end

caps to prevent dirt or water from entering the connectors

which may result in corrosion or poor contact.

5. Nicks or cuts in cable insulation should be immediately

sealed or repaired to prevent corrosion to the wire or

short circuits.

6. If an arc welder or any other source of high voltage will

be used on the tractor or implement, disconnect all

ground and power to prevent damage to the electronic.

Loading...

Loading...