17

Installation (cont.)

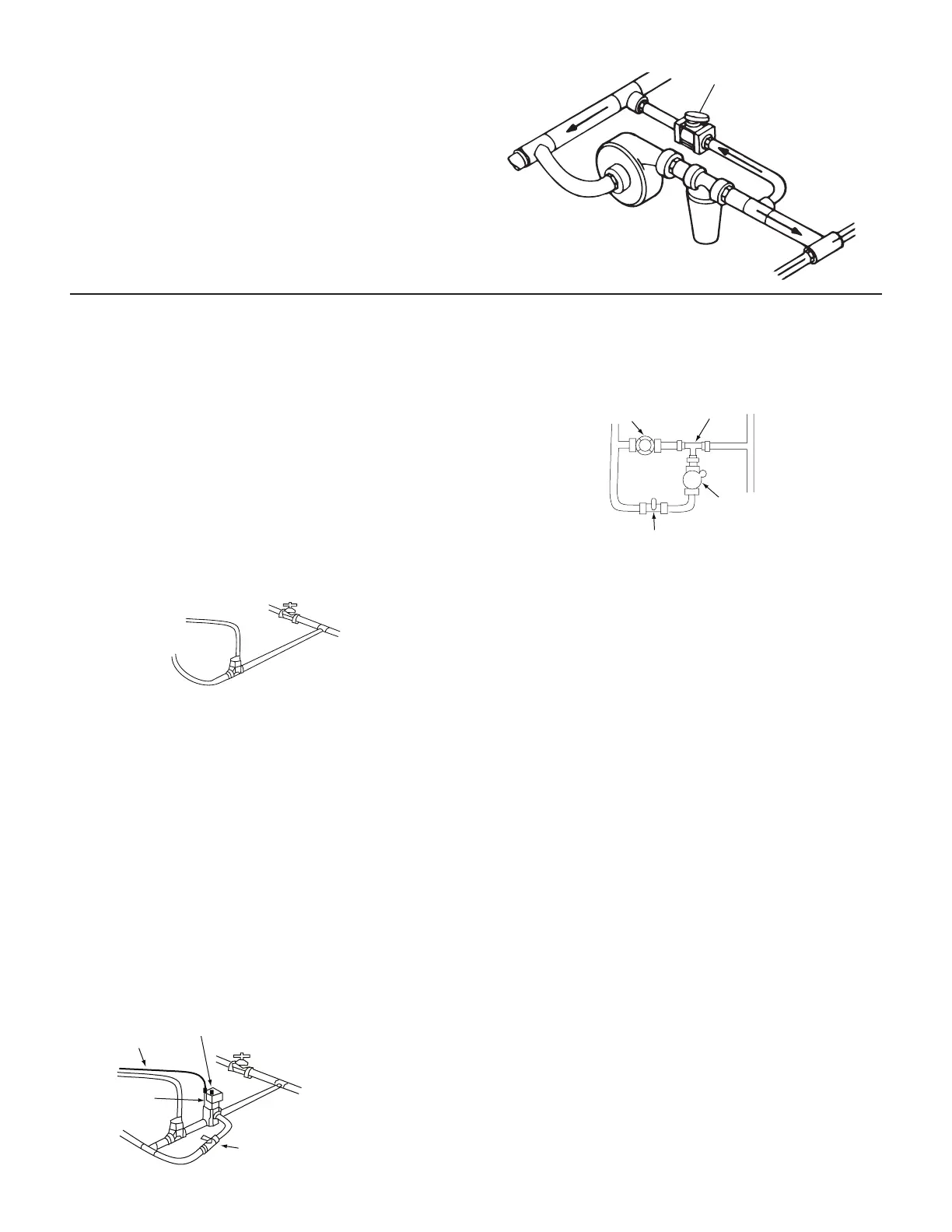

Range Adjust Valve

With over-sized pumps it may be necessary to install a range

adjust valve. The range adjust valve will make your pump

appear smaller to the rest of the system. Adjustment of this

valve is covered in the Pre-Field checkout on page 21.

Tee “C”

Adjust Valve

Tee “A”

For oversized pumps

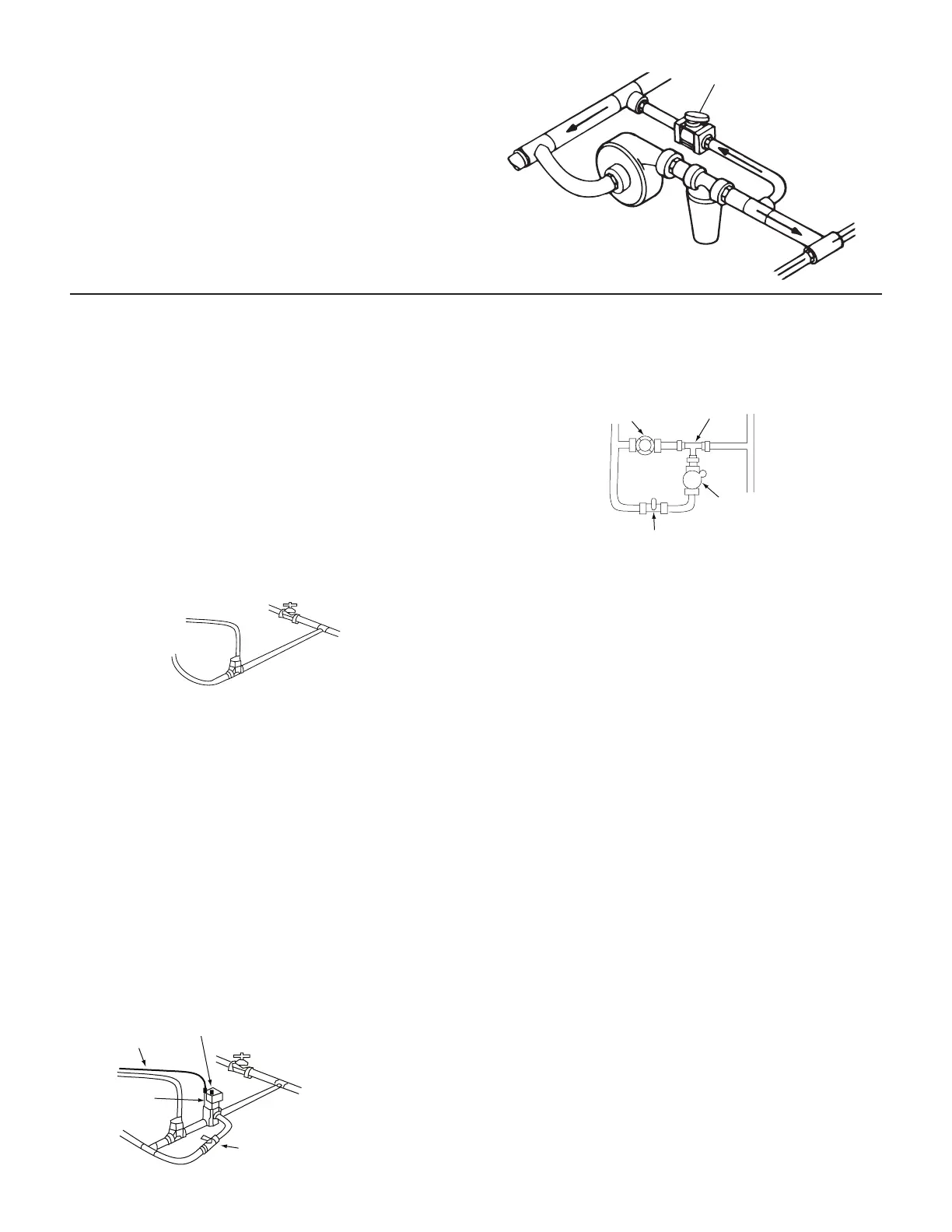

Servo, Throttling & Boost Valves

Although installing boost valve does involve additional

expense, it offers instant flow response and assures sufficient

by-pass by automatically opening when a boom is shut off.

1. When Servo and throttling valves are installed without

boost solenoid the outlet of the servo valve must be

connected directly to the pump inlet or into the tank

with no restrictions. Connection to the agitation line will

probably cause slow response and marginal operation.

Connect the 5’ (1.5 m) servo cable (reverse connector

and orange boost valve wire) to the servo.

NOTE: If boost valve is not used, tape off orange with to

prevent shorting to frame. (If this wire shorts to frame

ground, the internal circuit breaker will trip, turning booms

off and stopping acre count.)

NOTE: The servo may connect directly to the servo lead on

the main harness (reversed connector). If more length is

needed use the 5” (1.5 m) servo cable.

2. Use this plumbing diagram if your boost valve has flo-

thru port. Crimp 1 female tab terminal onto ORANGE

wire of servo valve cable (reversed connector.) Slip it

on boost solenoid terminal. Cut a length of 14 Ga. BLUE

hook-up wire and crimp a female tab terminal on one

end and a ¼” ring terminal on the other. Ground other

solenoid terminal using this wire.

SERVO

VALVE

“T” FITTING

BOOST ADJUST

BOOST

SOLENOID

VALVE WITHOUT

BOOST SOLENOID

SERVO

VALVE

CABLE

FROM PUMP

THROTTLE

VALVE

SERVO

RETURN

TO BOOMS

BOOST

SOLENOID

BOOST

ADJUST

ORANGE

CONNECT TO

FRAME GROUND

SERVO AND THROTTLE

VALVE WITH

BOOST SOLENOID

WARNING: Do not use the MT-3000 pressure gauge for

toxic chemicals or materials in compatible with nylon,

EPDM, brass, tin/lead solder or phosphor bronze (such as

liquid fertilizer). Use a suitable gauge mounted in a safe

location or install a gauge protection (diaphragm).

Three fittings are provided for the pressure line: a female

elbow, a male connector and a union for quick connection

at the hitch. The fittings have pre-installed “O” rings which

should be replaced with the 4 EPDM “O” rings supplied. Also

supplied is a small snubber washer to be installed in the

male connector. (The snubber washer allows pressure, not

volume, to get to the pressure gauge. Should the tube break

it will seep slowly rather than spray vigorously.

3. If your boost valve does not have flo-thru port, you must

add a “T” fitting.

NOTE: To assure a good connection and avoid corrosion,

coat servo and solenoid lugs with silicone grease.

Ground “Jumper” Installation

If you are spraying with a drawn implement, you must

attach a ground wire “jumper” to complete the electrical

circuit across the hitch for the solenoid valves. One end is

connected to sprayer hitch, the other to your tractor frame.

Cut 2 appropriate lengths of 14 Ga. BLUE wire.. Crimp a ¼”

ring terminal to one of each. Crimp a male tab terminal on

the other end of one wire and a female tab terminal to the

other wire,

Using ¼” bolts, attach one wire to implement frame and the

other to the tractor. Plug the male and female tab terminals

together. Always apply silicone grease to exposed or partially

exposed electrical connections to prevent corrosion.

Loading...

Loading...