18

Installation (cont.)

Servo, Throttling & Boost Valves (cont.)

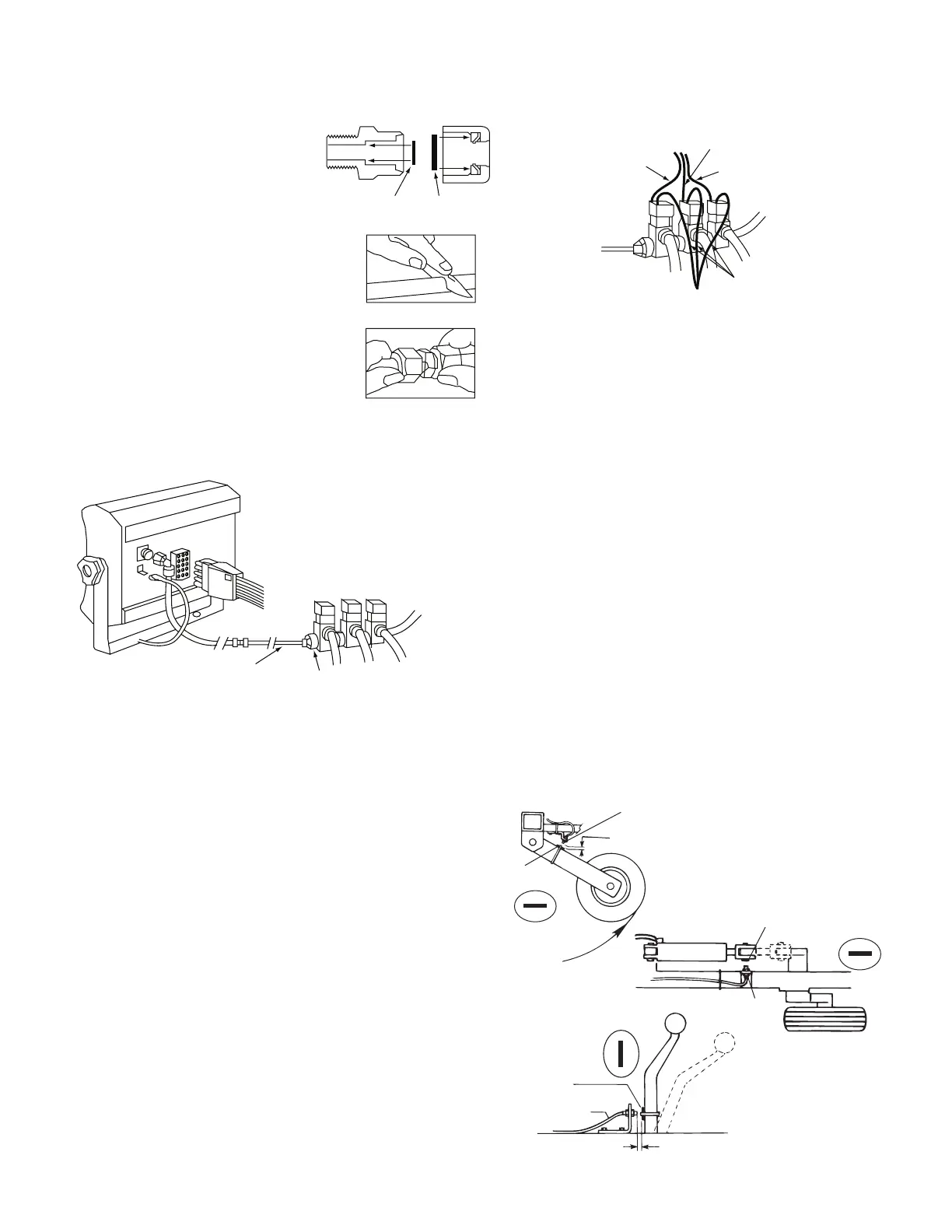

1. Disassemble fittings and replace

“O” rings with those supplied.

Insert snubber washer into male

fitting.

2. Measure length and cut tubing

at slight angle for easy insertion.

3. Loosen nut on fitting until 3

threads are visible.

4. Moisten end of tubing and

insert straight into fitting until

it bottoms out. Tighten nut by

hand.

5. Connect tubing to inlet side

of solenoid valves using

appropriate adapter fittings. Attach elbow fitting to

console. Route tubing along wire harness and secure

with plastic ties.

SNUBBER

WASHER

“O” RINGS

UNION

MALE

FITTING

¼” PRESSURE

LINE TO SPRAYER

REDUCTION FITTING

(NOT SUPPLIED)

FLOW IN

Boom Solenoid Valves

Plumb solenoids with flo-thru port as shown. Solenoids of

different design may require a “T”. Use lines large enough to

minimize pressure drops.

Locate 3’ (1 m) solenoid cable (BLACK cable tie near

connector). Crimp female tab terminal on RED, WHITE

and BLACK wires. Slip red wire onto left boom solenoid,

white onto center and black onto right. To assure a good

connection and avoid corrosion, apply silicone grease to

solenoid lugs.

Make 3 ground wires of appropriate length using 14 Ga.

BLUE wire. Crimp female tab terminal on one end of each

wire and ¼” ring terminal on the other. Slip female terminals

onto solenoid terminals. Bolt ¼” ring terminals to a good

frame round. Secure wires with plastic ties and plug into

main harness cable having BLACK cable tie near connector.

Sensor (Black body)

1/8” to 3/8”

(6 mm to 13 mm)

when wheels are up

Magnet

South

North

1/8” to 3/8 “ (6 mm to 13 mm)

space when equipment is

down and operating

Sensor Cable

(black body)

Magnet

South

North

Run Position

Hold

Position

Run

Position

Hold

Position

Sensor

(Black body)

Magnet

North

South

NOTE: If you are using electric boom solenoids, you may

have to install a light bulb or some other 12 volt load in

place of the solenoids to get the monitor to acknowledge

boom widths and count area.

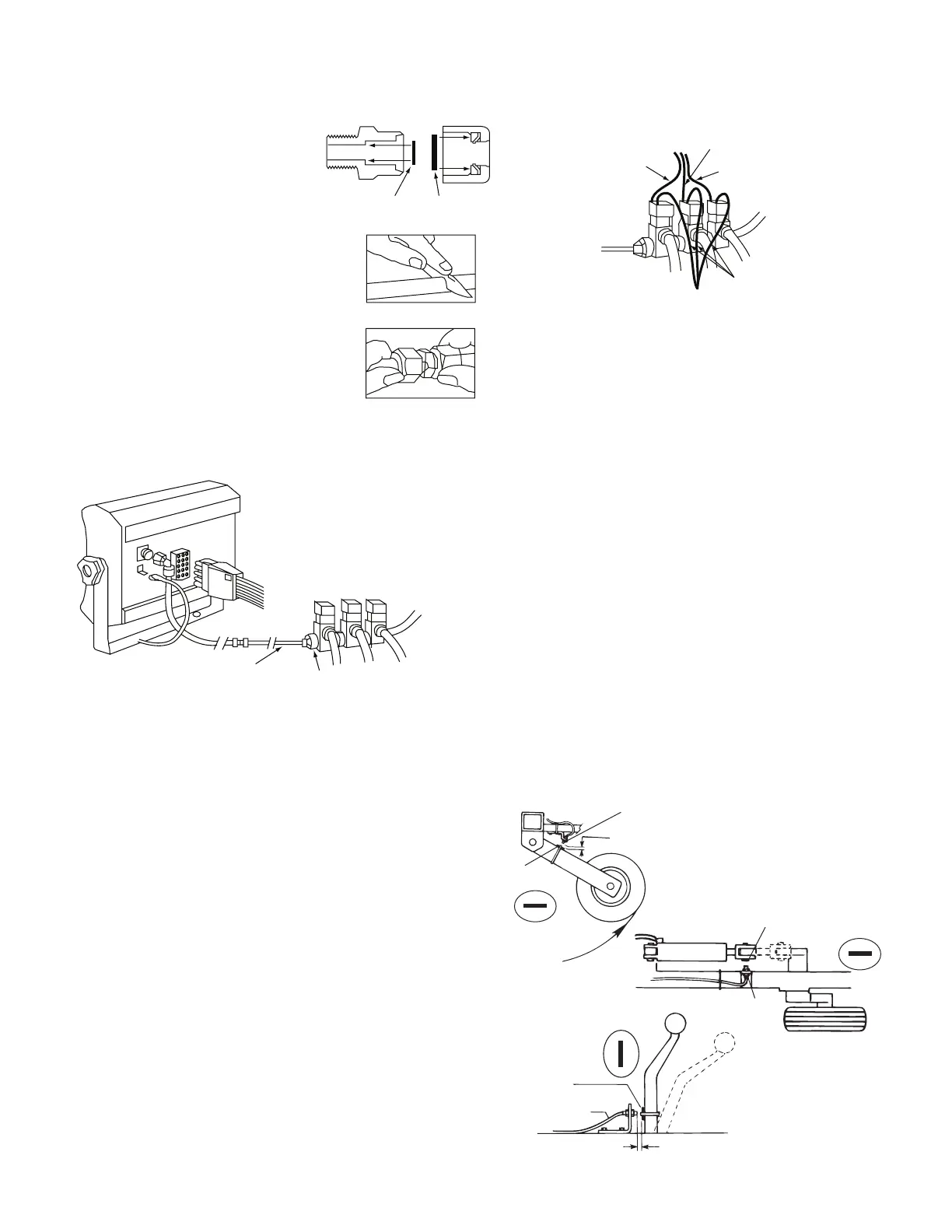

Optional Remote Run/Hold Installation

The remote Run/hold (shortest cable on the main harness)

option automatically turns the solenoid valves off and stops

the acre accumulation when equipment is raised, such

as turning on end rows. The remote sensor overrides the

console when the master switch is in the AUTO or MANUAL

position. (The remote sensor is the same as the magnetic

speed sensor and has a YELLOW cable tie near the connector.

The basic idea is to attach a magnet to a lever or some part

of the equipment that moves when the implement is raised

and lowered. When the magnet is away from the sensor the

console will be in HOLD and will shut off the solenoid valves

and stop counting acres.

NOTE: The Run/’Hold sensor is 3 feet (1 m) long. You may

require extension cables which are available in 5 ft. (1.5 m),

10 ft. (3 m), 15 ft. 4.5 M) and 20 ft. (6 m) lengths.

You may also use a toggle or other type switch. Simply

cut the BLUE jumper wire in the dust cover and splice on

a appropriate length of wire to reach your switch. When

switch is closed, console is in RUN (provided master switch

is in AUTO or MANUAL). When switch is open, console is in

HOLD.

BLACK

WHITE

RED

BLUE

WIRES

CONNECT TO

FRAME GROUND

Loading...

Loading...