Anhydrous Ammonia (cont.)

Flowmeter Cleaning Procedure

NOTE: Cleaning the flowmeter does not require loosening

the pipe thread fittings. The fittings are pressure tested and

precisely adjusted to fit the brackets. Do not disassemble

them. The entire servo/flowmeter assembly is removed

as a single unit, elbows and all. The silver colored fittings

between the elbows and the heat exchanger are unions.

To remove the assembly, loosen the union hex closest to

the heat exchanger. Remove the two U-bolts that hold

the servo/flowmeter assembly to the brackets. Unscrew

the union from the heat exchanger and remove the servo/

flowmeter assembly.

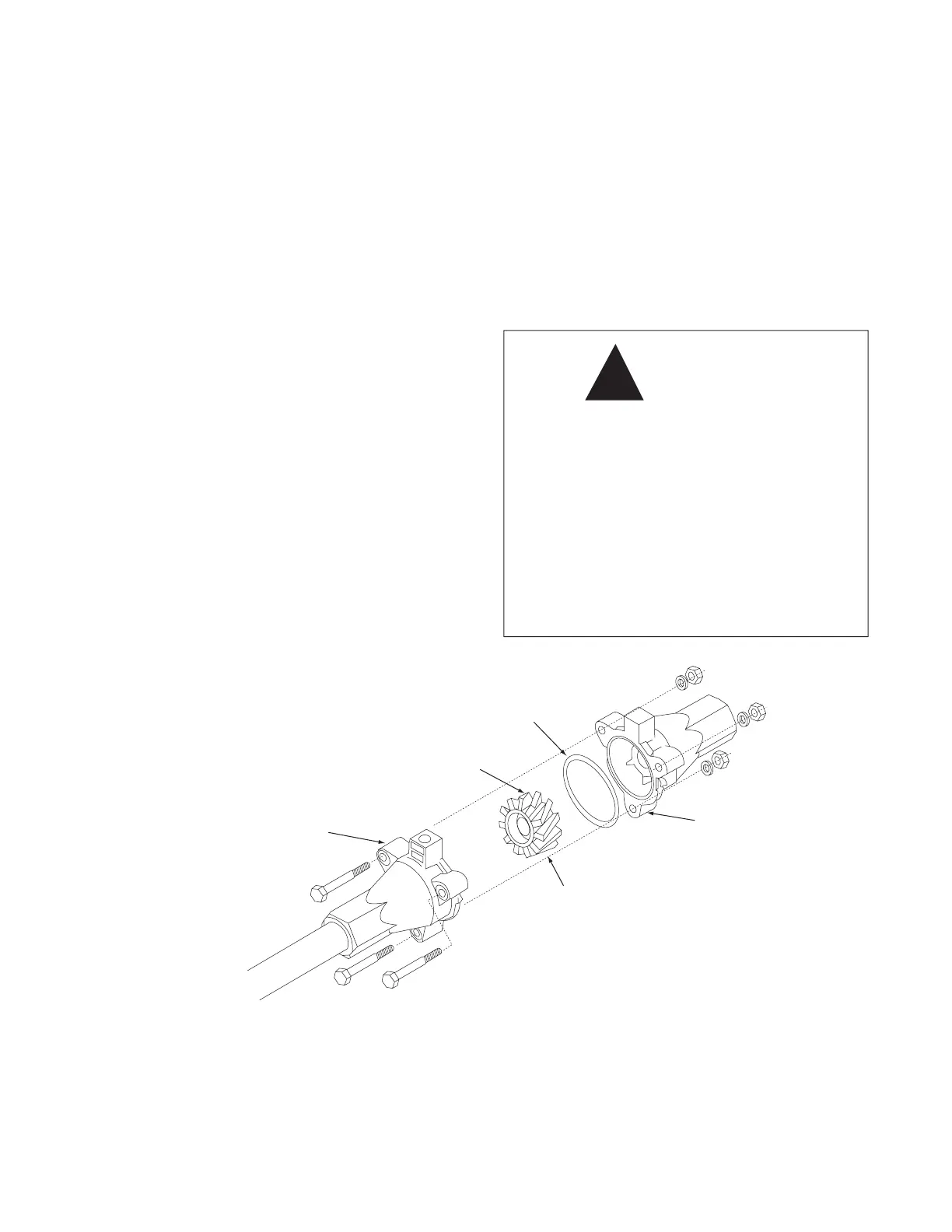

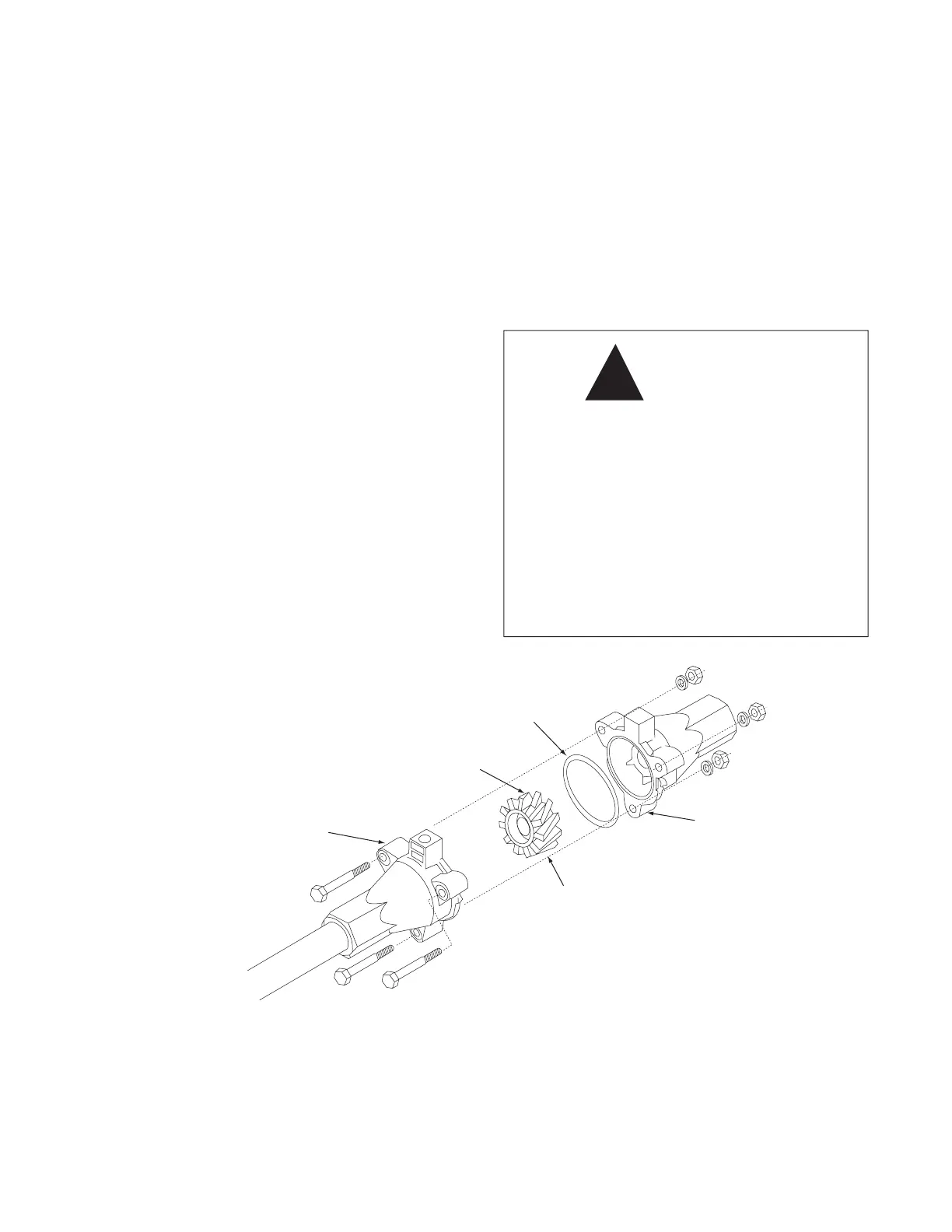

Use running water to rinse the assembly of any accumulated

dirt. Remove the three flowmeter bolts, carefully open the

flowmeter and remove the turbine. Thoroughly clean the

turbine and housings of any foreign material (dirt, pieces of

teflon tape, rust on magnets, etc.).

Set and spin the turbine in each flowmeter housing half.

(Turbine goes magnets down in the sensor housing and

magnets up in the non-sensor housing). It should spin freely.

If not, remove the turbine, wipe the shaft and try again.

Place the servo, flowmeter end up, in a vice or other suitable

fixture. Set turbine, magnets up, in non-sensor housing.

(Magnets must line up with hole for sensor). Properly

position gasket on housing. Gasket may be reused as few

times but will eventually need to be replaced). Pipe thread

compound is not absolutely necessary but will insure a good

!

WARNING

Always follow standard safety

procedures and use proper

safety equipment when working

on anhydrous ammonia equipment

Before working on plumbing:

• Disconnect nurse tank.

• Remove all ammonia from system

• Leave all valves on applicator open.

seal. Be careful not to get compound inside flowmeter or

turbine will stall. Carefully put other flowmeter housing

(sensor half) in place. Position the housing so that the two

square lugs are lined up with each other. Drop all three bolts

into holes. Hold lock washers in place and finger tighten

nuts. Making sure gasket is still properly aligned, evenly

tighten all three nuts. Nuts should be torqued to 1 ft./lb.

(1.35 Nm). Attach tag by running wire between a bolt and

the housing and twist.

After assembly, shaking flowmeter end for end should

produce a “rattling” sound (shaft end play).

Start with original calibration number and follow procedure

in manual for verifying flowmeter accuracy.

GASKET

P/N 10137

MAGNETS MUST

FACE SENSOR

HOUSING

TURBINE WITH

2 MAGNETS

P/N 10091

HOUSING WITH

SENSOR RECEPTACLE

INCLUDES BEARING

HOUSING,

INCLUDES

BEARING

43

Loading...

Loading...