M thermal Mono

202005 77

Part 3 - Installation and Field Settings

That in case of an installation with a domestic hot water tank, only the use of propylene glycol is allowed. In other

installations the use of ethylene glycol is fine.

That no automotive glycol is used because their corrosion inhibitors have a limited lifetime and contain silicates that

can foul or plug the system;

That galvanized piping is not used in glycol systems since it may lead to the precipitation of certain elements in the

glycol’s corrosion inhibitor;

To ensure that the glycol is compatible with the materials used in the system.

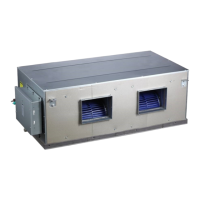

3.5 Water Flow Switch

Water may enter into the flow switch and cannot be drained out and may

freeze when the temperature is low enough. The flow switch should be

removed and dried, then can be reinstalled in the unit.

Counterclockwise rotation, remove the water flow switch.

Drying the water flow switch completely.

3.6 Adding Water

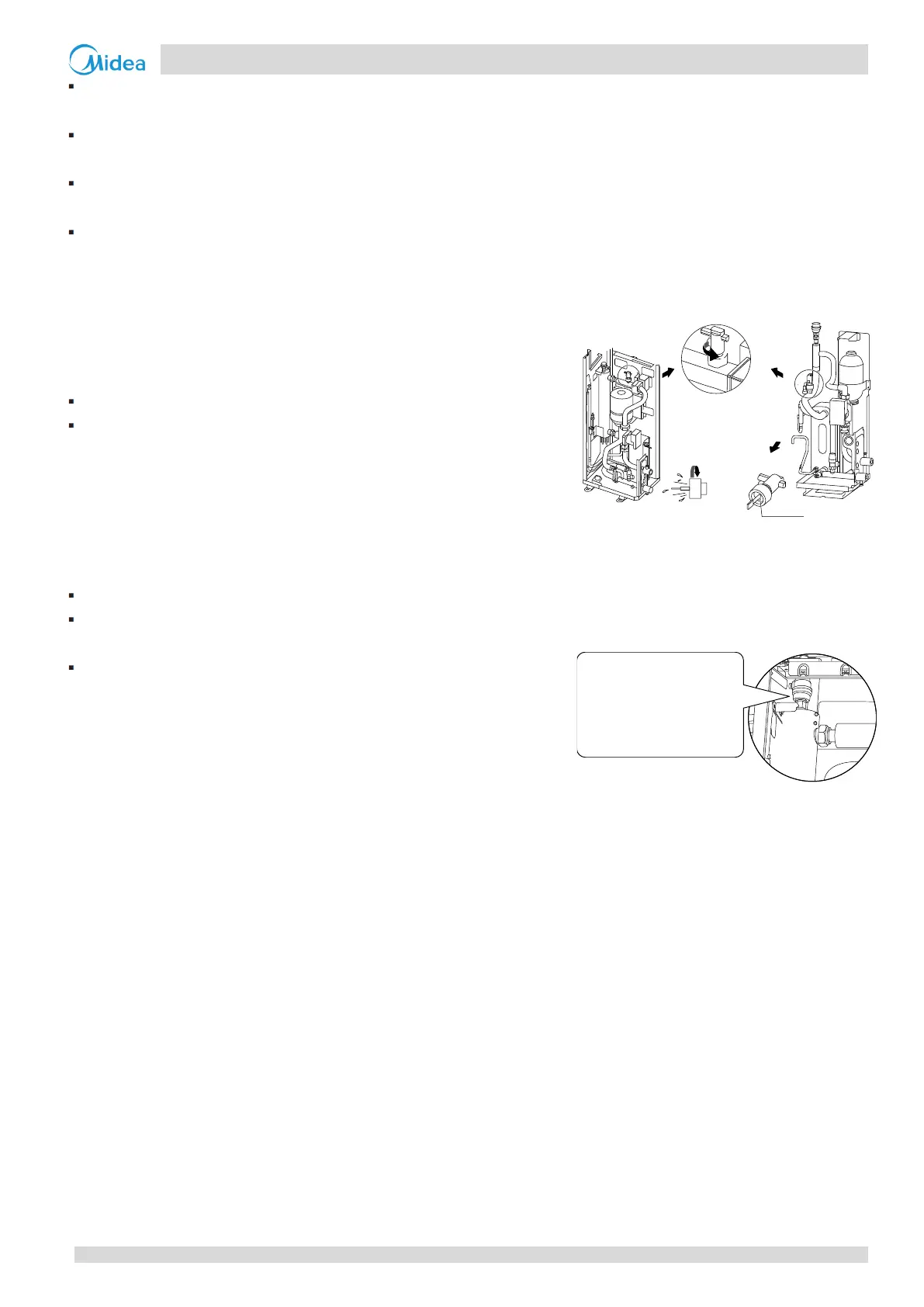

Connect the water supply to the fill valve and open the valve.

Make sure the automatic air purge valve is open (at least 2 turns).

Refer to Figure 3-3.3.

Fill with water until the manometer indicates a pressure of

approximately 2.0 bars. Remove air in the circuit as much as possible

using the air purge valve. Air in the water circuit could lead to

malfunction of the backup electric heater.

3.7 Water Piping Insulation

The complete water circuit including all piping, water piping must be insulated to prevent condensation during cooling

operation and reduction of the heating and cooling capacity as well as prevention of freezing of the outside water piping

during winter. The insulation material should at least of B1 fire resistance rating and complies with all applicable legislation.

The thickness of the sealing materials must be at least 13mm with thermal conductivity 0.039W/mK in order to prevent

freezing on the outside water piping. If the outdoor ambient temperature is higher than 30°C and the humidity is higher

than RH 80%, the thickness of the sealing materials should be at least 20mm in order to avoid condensation on the surface

of the seal.

Figure 3-3.2: Water flow switch

Figure 3-3.3: Air purge valve

Do not fastenthe black plastic

cover on the vent valve at the

topside of the unit when the

system is running. Open air

purgevalve,turnanticlockWise

atleast2 fullturnstoreleaseair

from the system.

Loading...

Loading...