11

Connection and operation

Warning

Read warning notice and

instruction manual carefully

prior to initial operation and

save the information for

later use.

Permissible installation

Mains connection

Connect the machine to the correct mains supply.

Please read the type plate (U

1

) on the rear side of the

machine.

0

l

1

2

Connection of shielding gas/plasma gas

Connect the gas hoses, which branch off from the back

panel of the welding machine (3), to a gas supply with

pressure regulator (2-6 bar) for shielding gas. (Note:

Some types of pressure regulators require an output

pressure of more than 2 bar to function optimally).

Connect the gas hose for plasma gas to 1-5 bar.

Important!

In order to avoid destruction

of plugs and cables, good

electric contact is required when

connecting earth cables and

welding hoses to the machine.

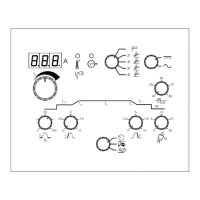

1. Mains connection

2. Power switch

3. Gas hose

4. Connection of shielding gas

5. Connection of plasma gas

6. Connection of TIG/PLASMA Welding hose

7. Connection of earth clamp (TIG/PLASMA) or electrode holder

8. Connection pilot arc (PLASMA)

9. Connection 7-pole plug (TIG)

10. Connection of cooling hoses - internal cooling TIG 500A/PLASMA 80A

11. Connection of cooling hoses - internal cooling TIG 500A/PLASMA 80A

12. Cooling liquid level control

13. Refill of cooling liquid

14. Connection of remote control

15. Connection of cooling hoses -

external cooling TIG 500A/PLASMA 350A

16. Connection of cooling hoses -

external cooling TIG 500A/PLASMA 350A

17. CAN connection

Gas 2-6 bar

Power

1

F

F

F

3

Plasma

gas

1-5 bar

3

15

16

2

14

5

8

4

6

7

9

10

11

12

13

15

16

17

Cooling Unit

rød/red/rot/rouge

Loading...

Loading...