OM-2240 Page 69

12-3. Stick Welding Procedure

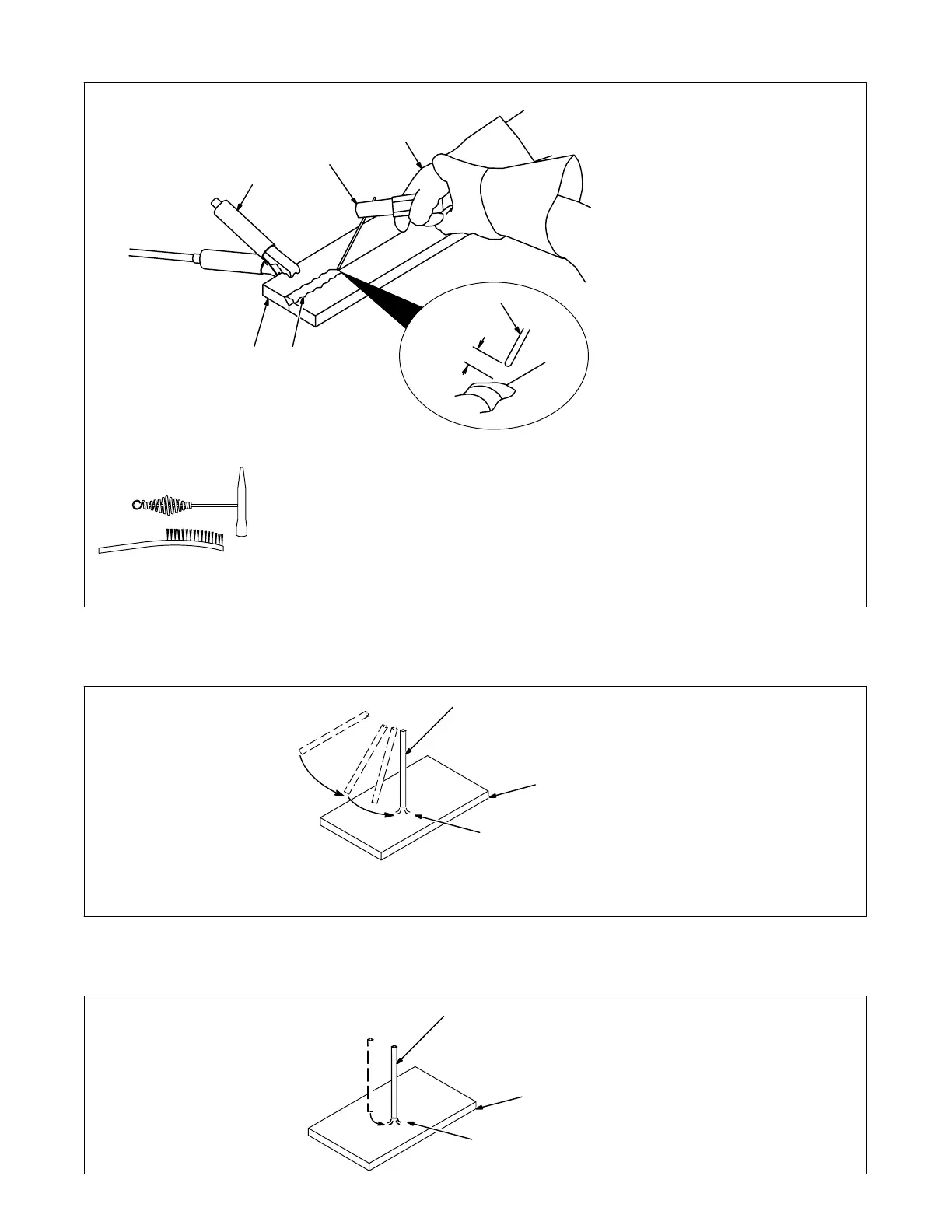

stick 12/96 − ST-151 593

Y Weld current starts when

electrode touches work-

piece.

Y Weld current can damage

electronic parts in vehicles.

Disconnect both battery

cables before welding on a

vehicle. Place work clamp as

close to the weld as possible.

1 Workpiece

Make sure workpiece is clean be-

fore welding.

2 Work Clamp

3 Electrode

A small diameter electrode requires

less current than a large one. Fol-

low electrode manufacturer’s

instructions when setting weld am-

perage (see Section 12-2).

4 Insulated Electrode Holder

5 Electrode Holder Position

6 Arc Length

Arc length is the distance from the

electrode to the workpiece. A short

arc with correct amperage will give

a sharp, crackling sound.

7 Slag

Use a chipping hammer and wire

brush to remove slag. Remove slag

and check weld bead before mak-

ing another weld pass.

Tools Needed:

1

4

3

5

2

7

6

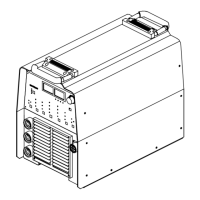

12-4. Striking an Arc − Scratch Start Technique

S-0049

1 Electrode

2 Workpiece

3 Arc

Drag electrode across workpiece

like striking a match; lift electrode

slightly after touching work. If arc

goes out electrode was lifted too

high. If electrode sticks to work-

piece, use a quick twist to free it.

Y Normal open-circuit voltage

(80 volts) is present if normal

open-circuit voltage is se-

lected (see Section 6-6).

1

2

3

12-5. Striking an Arc − Tapping Technique

S-0050

1 Electrode

2 Workpiece

3 Arc

Bring electrode straight down to

workpiece; then lift slightly to start

arc. If arc goes out, electrode was

lifted too high. If electrode sticks to

workpiece, use a quick twist to free it.

1

3

2