OM-353 Page 22

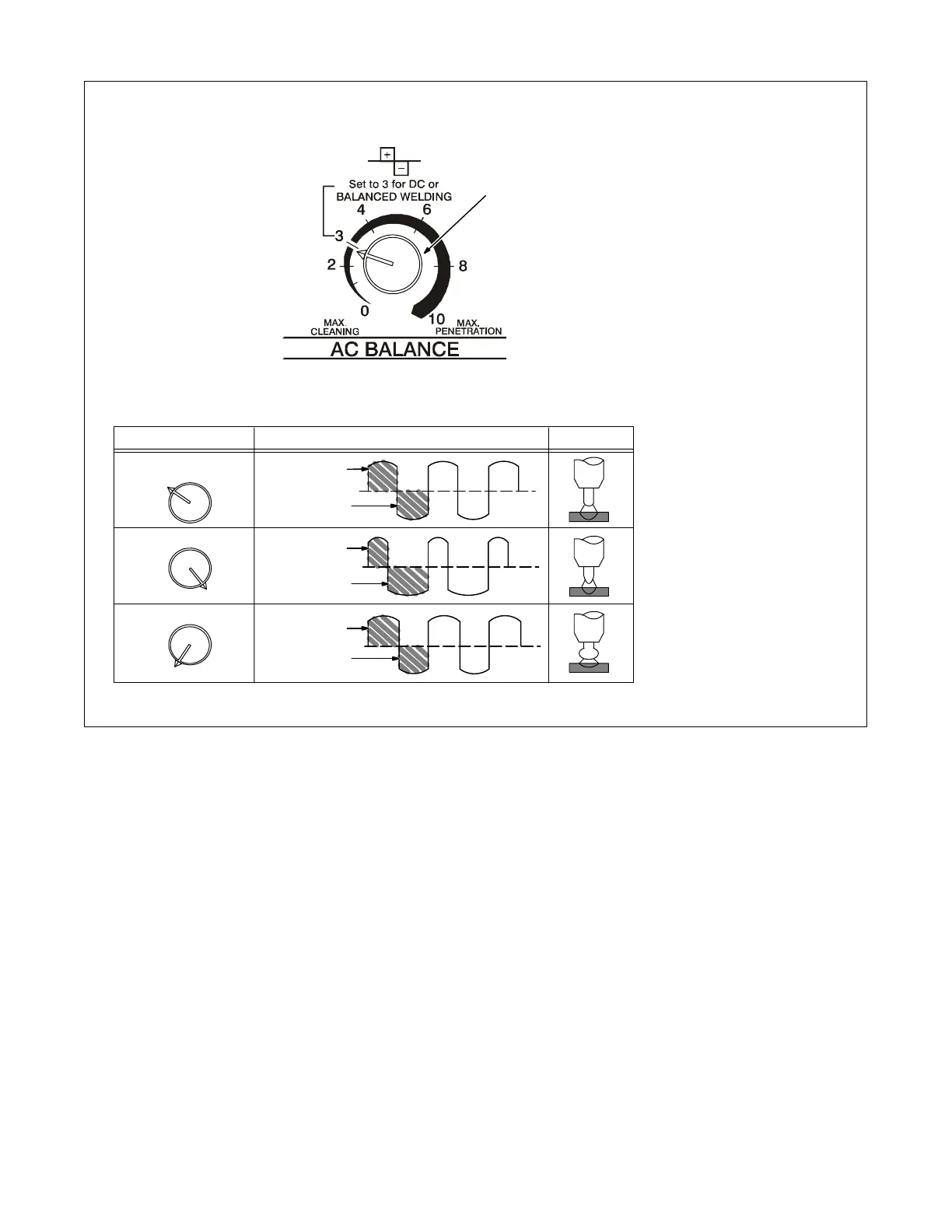

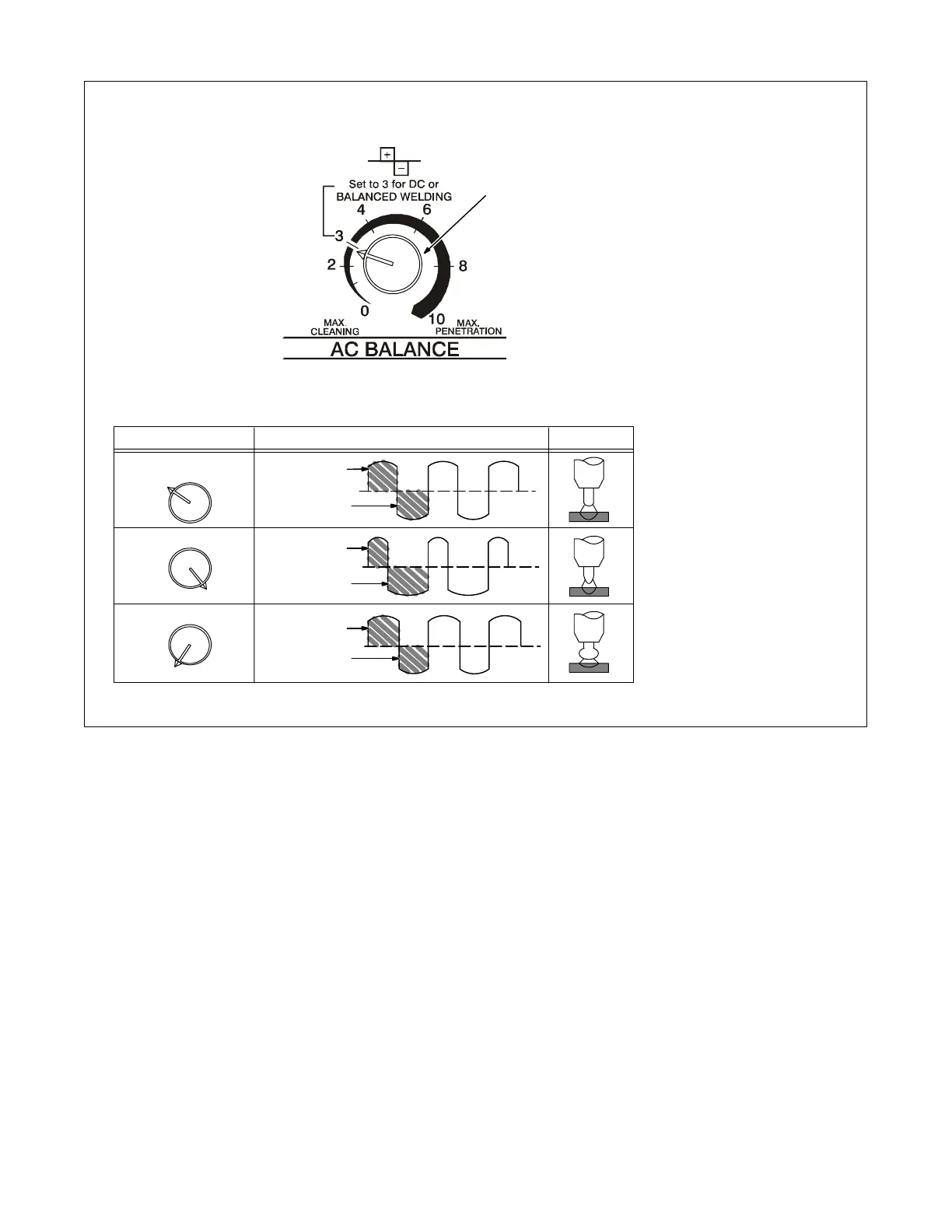

4-6. AC Balance Control

Ref. S-0795-A

1 AC Balance Control

Balance Control (AC GTAW):

Control changes the AC output

square wave. Rotating the control

towards 10 provides deeper pene-

tration. Rotating the control towards

0 provides more cleaning action of

the workpiece.

When the control is in the Balanced

position, the wave shape provides

equal penetration and cleaning

action.

Application:

When welding on oxide forming ma-

terials such as aluminum or magne-

sium, excess cleaning is not neces-

sary. To produce a good weld, only

a minimal amount, approximately a

0.10 in (2.5mm) of etched zone

along the weld toes is required.

Set control to 7 and adjust as nec-

essary. Joint configuration, set-up,

process variables, and oxide thick-

ness may affect setting.

Arc rectification can occur when

welding above 200 amps and/or

while welding with helium gas. If this

condition occurs, increasing the

Balance control towards maximum

penetration, may help to restabilize

the arc.

Balanced

3

10

0

More Penetration

More Cleaning

50% Electrode

Positive

50% Electrode

Negative

32% Electrode

Positive

68% Electrode

Negative

55% Electrode

Positive

45% Electrode

Negative

Output Waveforms ArcSetting

1

Loading...

Loading...