OM-353 Page 24

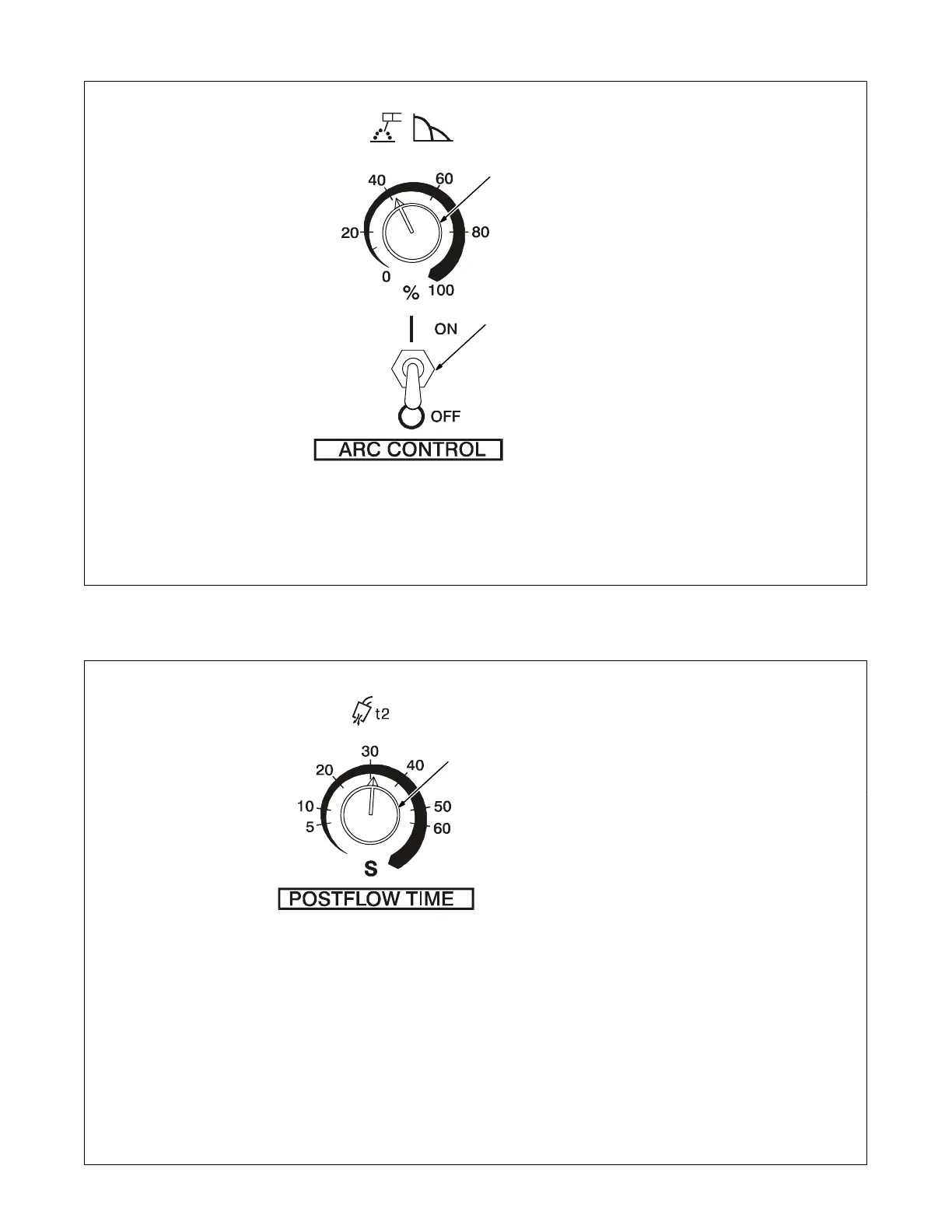

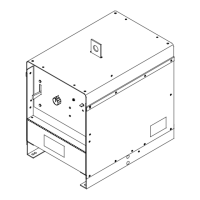

4-9. Arc Controls

1 Arc Control (Dig)

For AC And DC SMAW Welding

When set at 0, short-circuit amper-

age at low arc voltage is the same

as normal welding amperage.

When setting is increased, short-

circuit amperage at low arc voltage

increases.

Set at 0 for GTAW welding.

2 Arc Control Switch

Place switch in the ON position to

turn on arc control circuitry. When

switch is in the OFF position, no ad-

ditional amperage is available at

low arc voltages. Place switch in

the OFF position while performing

Gas Tungsten Arc Welding

(GTAW).

Application:

Control helps arc starting or making

vertical or overhead welds by in-

creasing amperage at low arc volt-

age, and reduces electrode sticking

while welding.

2

1

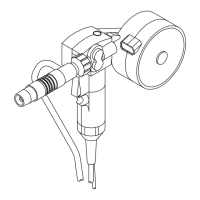

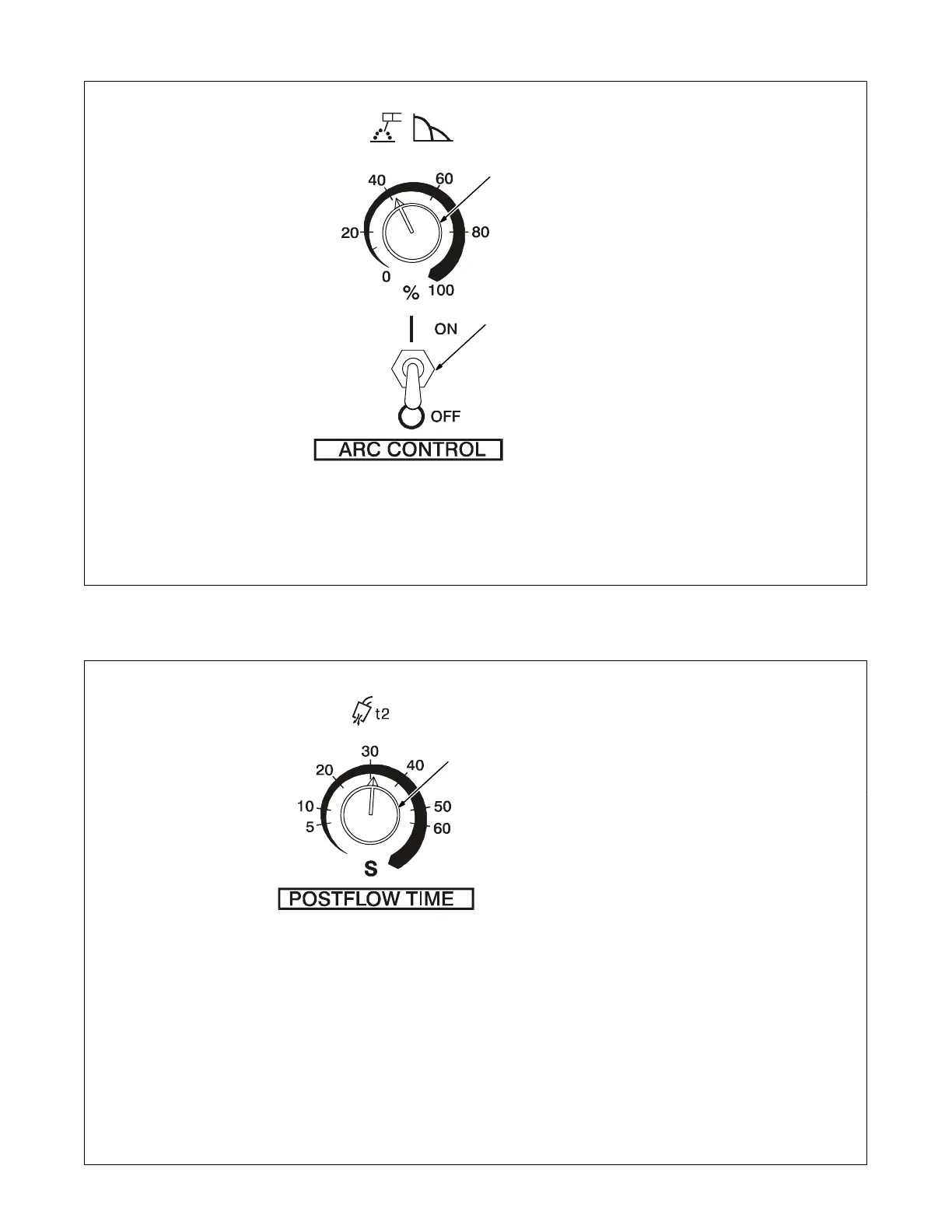

4-10. Postflow Time Control

1 Postflow Time Control

Use control to set length of time

(0–70 seconds) gas flows after

welding stops. It is important to set

enough time to allow gas to flow un-

til after the tungsten and weld

puddle has cooled down.

Application:

Postflow is required to cool tung-

sten and weld, and to prevent con-

tamination of tungsten and weld. In-

crease postflow time if tungsten or

weld are dark in appearance.

1

Loading...

Loading...