OM-353 Page 25

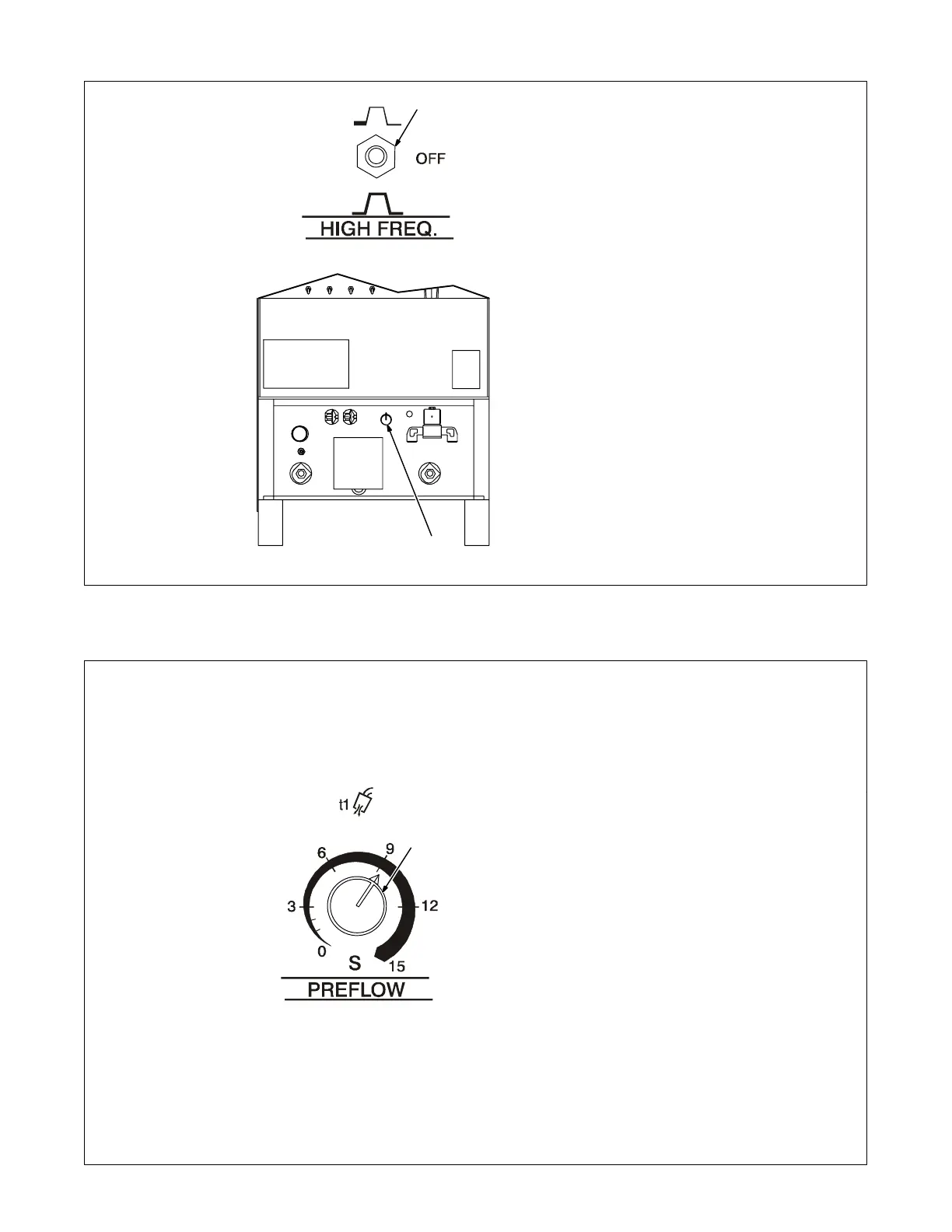

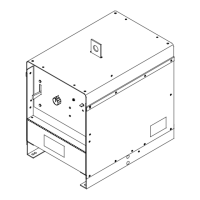

4-11. High Frequency Controls

Y Place High Frequency

switch in Off position before

using the shielded metal arc

welding (SMAW) process.

1 High Frequency Switch

START – (Up position) provides HF

for arc starting only. High frequency

turns on to help start arc when out-

put is enabled. High frequency

turns off when arc is started, and

turns on whenever arc is broken to

help restart arc.

Application:

HF Start is used when the DCEN

GTAW process is required.

OFF – provides no HF. Use OFF for

SMAW (stick electrode) welding.

CONTINUOUS – (Down position)

provides HF continuously through-

out the weld.

Application:

HF Continuous is used when the

AC GTAW process is required.

2 High Frequency Intensity

Control

Use control to change amount of

HF energy used to start and main-

tain the arc. Set as low as practical

to prevent interfering with electronic

equipment.

1

2

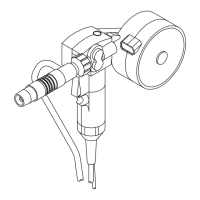

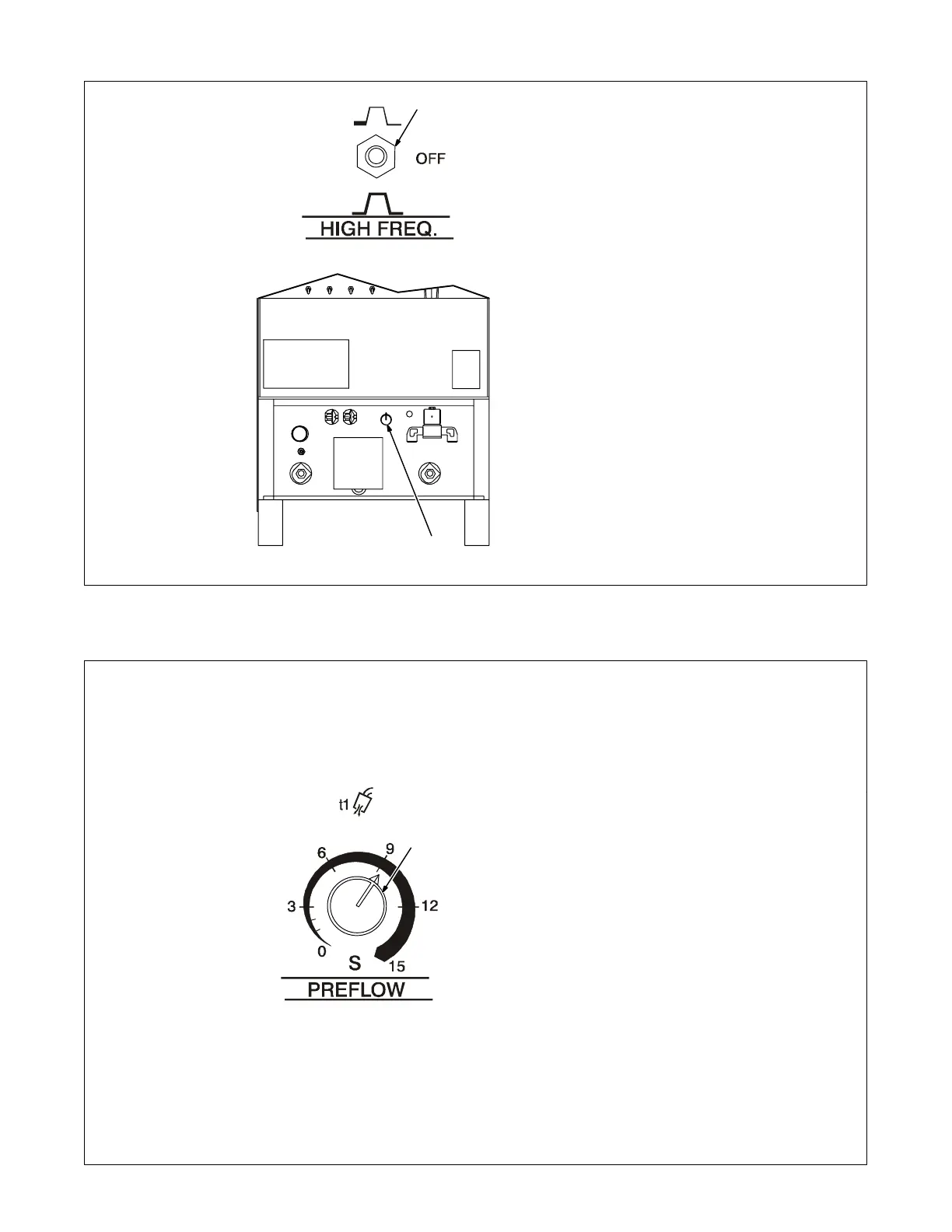

4-12. Preflow Time Control (Optional)

1 Preflow Time Control

Use control to set the length of time

(0–15 seconds) that gas flows be-

fore an arc is started.

Application:

Preflow is used to purge the imme-

diate weld area of atmosphere. Pre-

flow also aids in consistent arc

starting.

1

Loading...

Loading...