What to do if Miller Trailblazer 325 Diesel Welding System engine cranks but does not start?

- AAmanda MendozaAug 26, 2025

If the engine cranks but does not start, check the fuel level and front panel fault indicators.

What to do if Miller Trailblazer 325 Diesel Welding System engine cranks but does not start?

If the engine cranks but does not start, check the fuel level and front panel fault indicators.

Why is there no or low generator power output at AC receptacles on my Miller Trailblazer 325 Diesel Welding System?

If you have no or low generator power output at the AC receptacles but the weld output is okay, try resetting the supplementary protectors. Also, press the GFCI receptacle Reset button. Check the engine ignition wiring connections. If the problem persists, have a Factory Authorized Service Agent check the brushes and slip rings.

| Duty Cycle | 100% |

|---|---|

| Fuel Capacity | 12 gallons |

| Welding Amperage Range | 20 - 325 A |

| Engine Power | 24.8 hp (18.5 kW) |

| Maximum Output | 325 Amps |

| Type | Engine Driven Welding Generator |

| Rated Output | 325 A |

| Max Open Circuit Voltage | 80 VDC |

| Welding Processes | Stick (SMAW), TIG (GTAW), MIG (GMAW), Flux-Cored (FCAW) |

| Generator Power | 10, 000 Watts (Peak) |

| Auxiliary Power | 120/240 VAC |

Hazards associated with compressed gas cylinders, including explosion risk if damaged.

Hazards associated with compressed air equipment, systems, and air streams.

Covers various additional hazards not categorized elsewhere.

Details potential hazards associated with arc welding processes and equipment.

Hazards from sparks, metal fragments, and slag during welding operations.

Details hazards related to the engine, including battery, fuel, and moving parts.

Risks from improper installation or operation of compressed air equipment.

Risks of motor damage due to overheating and avoiding low voltage.

Risks from inhaling welding fumes and gases; ventilation and respirator requirements.

Hazards associated with battery handling, including explosion risk from gases.

Hazards from flying sparks and the need for face protection.

Hazards from sparks, hot materials, and flammable atmospheres during welding.

Risks of fire and explosion related to fuel handling and storage.

Dangers associated with moving parts.

Dangers of compressed air itself, including pressure relief and air streams.

Risks from intense visible and invisible rays produced by the welding arc.

Prohibition of using compressed air for breathing due to toxicity.

Hazards related to battery charging, including explosion and acid exposure.

Dangers from high-pressure fluids in fuel systems.

Warning about touching hot compressor or air system parts.

Risks of burns from hot steam and coolant, especially during checks.

Consequences of overuse leading to overheating.

Extreme danger of carbon monoxide poisoning from generator exhaust indoors.

Explains duty cycle and the risks of overheating the unit.

Details welding modes, output, generator power, fuel capacity, and engine specifications.

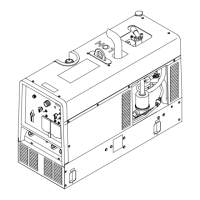

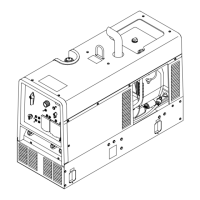

Details pre-start checks and provides an overview of engine components.

Provides detailed descriptions of each front panel control and indicator light.

Explains the function and settings of the process/contactor switch.

Explains how to adjust arc control settings for different welding processes.

Explains the Lift-Arc TIG process and its Auto-Stop and Auto-Crater features.

Details remote receptacle, process switch, and adjust/select controls.

Outlines routine maintenance tasks and their recommended intervals.

Details specific maintenance procedures for the engine, including oil, fuel, and coolant.

Lists common error displays and their descriptions for troubleshooting.

Provides tables to help diagnose and resolve common welding, generator, and engine problems.

Troubleshooting table for engine starting and running problems.