CHAPTER 6 - MAINTENANCE

Spindle Bearing Maintenance (some models)

Maintenance of the Spindle Bearing Grease

for Large Spindle Bore Lathes

(Applies to all 10” bore and above, and 6” bore w/ tapered roller bearings)

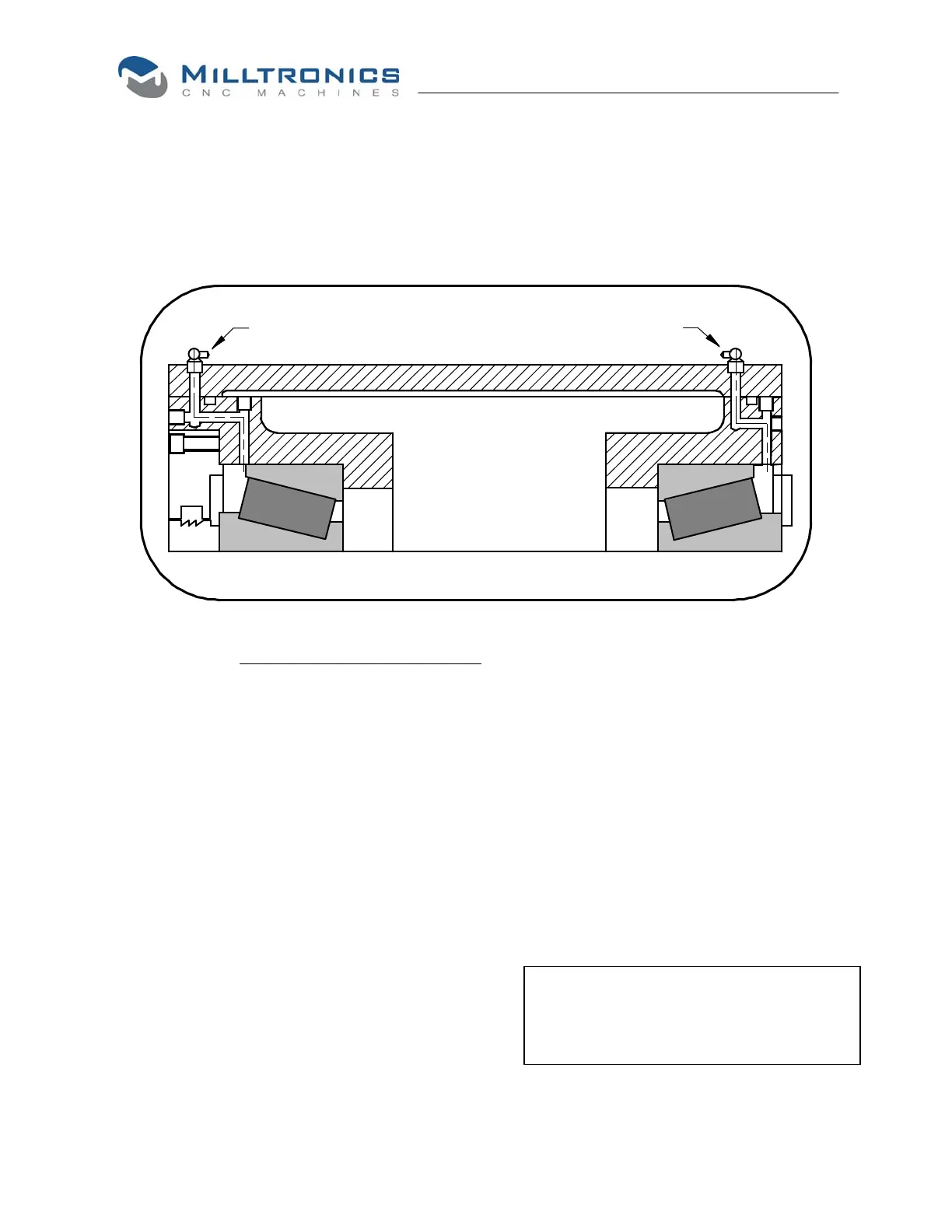

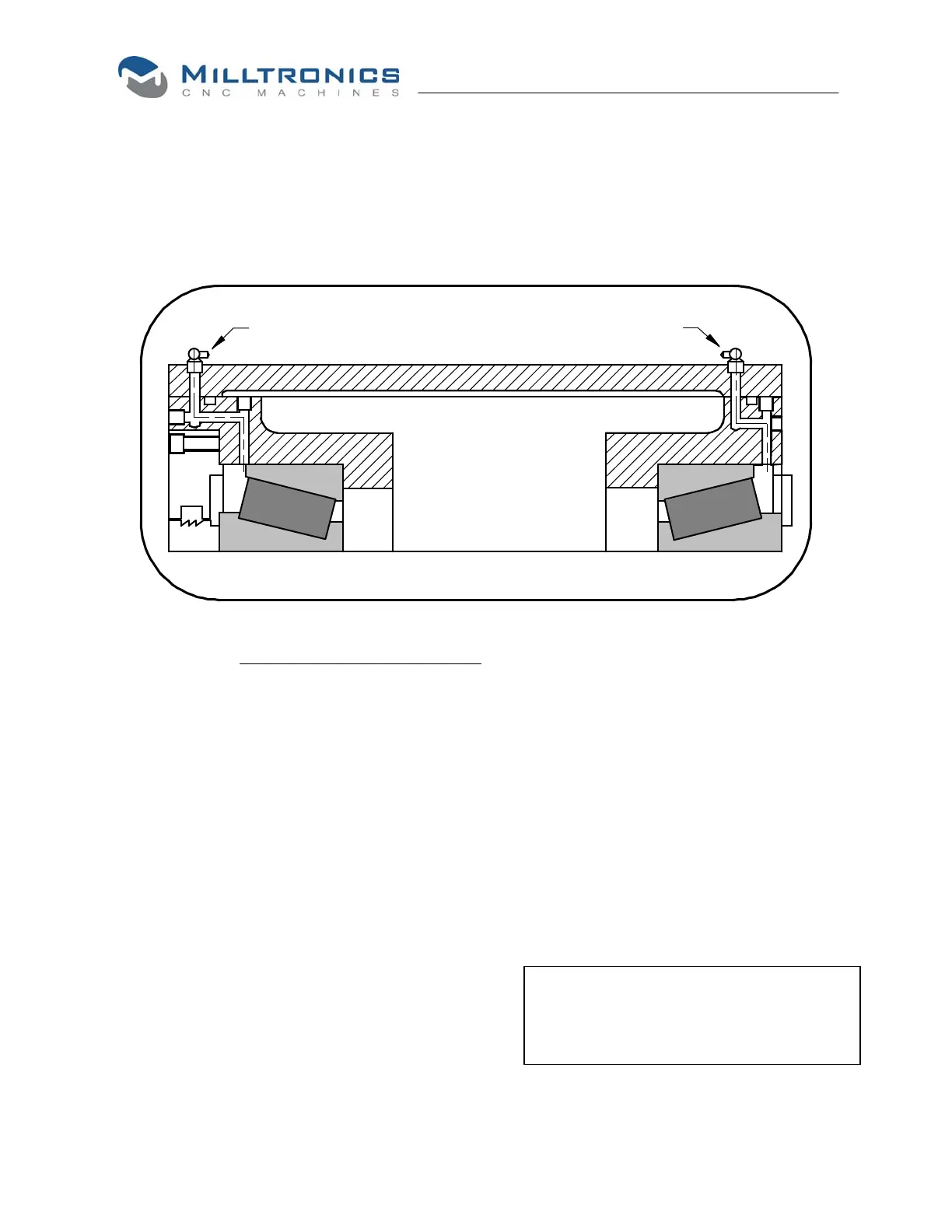

1 2

• Use only Kluber STABURAGS NBU 8 EP

grease or equivalent.

• Spindle should be greased 3 months after machine commissioning, then every 6 months

thereafter.

• Apply 30CC of grease at each of the lubrication points for spindle bores under 14”.

Spindle bores 14” and above require 50CC.

• Apply grease to fittings at points 1 and 2 at the top of the lathe headstock.

• To apply grease:

Power off the machine.

Turn spindle by hand as the grease is applied.

Klüber Lubrication North America L.P.

32 Industrial Drive

Londonderry, N.H. 03053

Tel: +1-603-647-410 4

+

-

-

-

49

Loading...

Loading...